Thickness gauge with replaceable probe and test method

A technology of thickness gauge and measuring head, which is applied in the field of thickness measuring instrument and testing with changeable measuring head, can solve the problems of not being able to meet the needs of measurement, limited conditions of use, easy wear of edge scales, etc., and achieve simple structure, Easy to grasp and easy to read

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

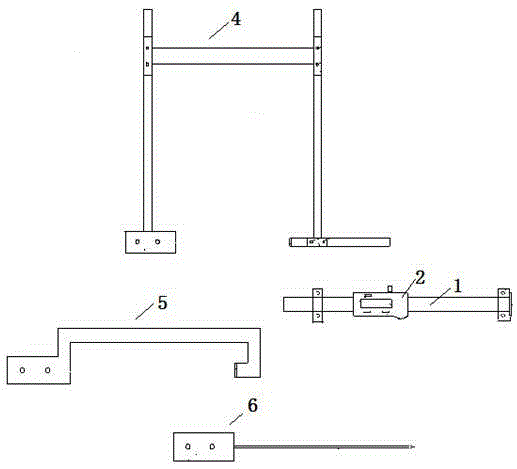

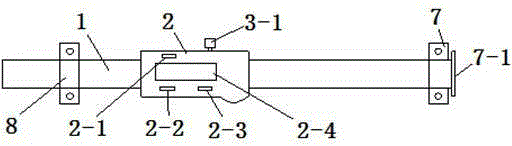

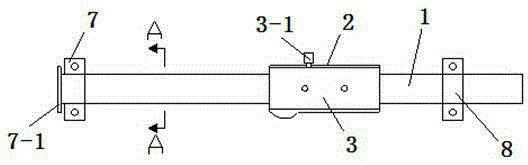

[0034] Such as Figure 1 to Figure 11 As shown, a thickness gauge with a changeable measuring head includes a mechanical scale 1, a digital display head 2, a scale slider 3, and also includes a movable U-shaped measuring head 4, a fixed U-shaped measuring head 5, and a needle-shaped measuring head. Measuring head 6, measuring base 7, positioning device 8.

[0035] A mechanical scale 1, a scale slider 3, a measuring base 7, a positioning device 8, and a digital display head 2 form a thickness gauge.

[0036] The mechanical scale 1 is equipped with a scale slider 3, and a positioning device 8 is fixed by a screw at one end of the mechanical scale 1. The fixed position of the positioning device 8 is the starting point of the size provided on the surface of the mechanical scale 1. Fix a measuring base 7 with screws, the surface of the positioning plate III7-1 on the measuring base 7 forms a vertical plane with the side of the other end of the mechanical scale 1, and fix the digit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com