A kind of impeller structure of turbine flowmeter and its turbine flowmeter

A technology of turbine flowmeter and impeller, which is applied in the field of flowmeter, can solve the problems such as the limitation of the range of use of turbine flowmeter, and achieve the effects of expanding the measurement range, small centrifugal force, and small flow velocity distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

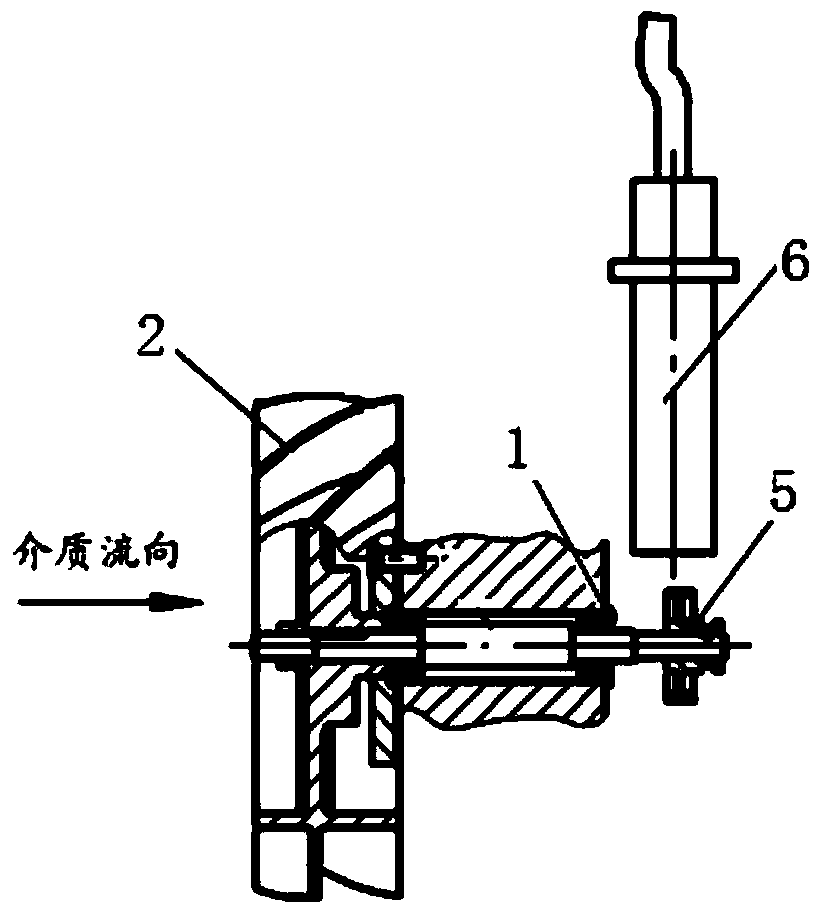

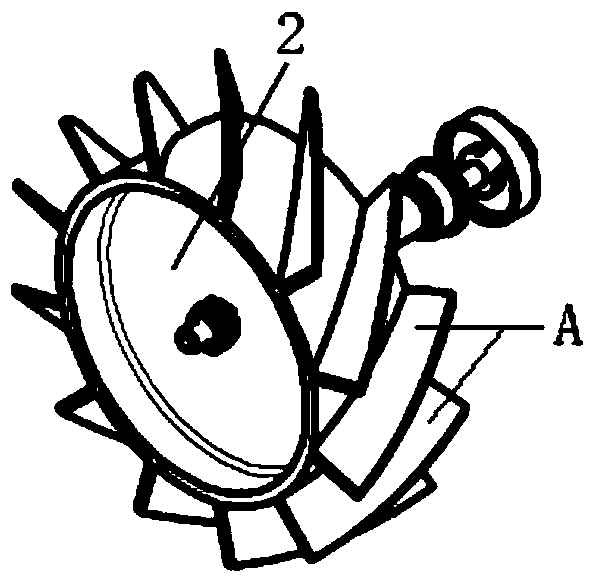

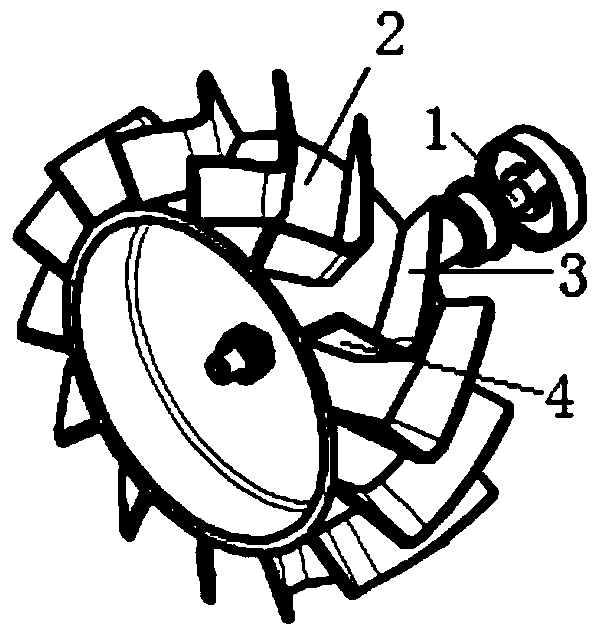

[0030] The invention discloses an impeller structure of a turbine flowmeter, such as image 3 , Figure 4 As shown, the impeller structure includes a bearing 1 and an impeller 2, wherein the impeller 2 is arranged on the bearing 1, and a plurality of blades are arranged at equal intervals on the impeller 2, and the plurality of blades respectively include a front blade 3 and a rear blade 4 forming a certain angle. , the front blade 3 and the rear blade 4 are distributed along the axial direction of the impeller 2, the torque on the front blade 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com