Electric automobile, and battery collector and battery system thereof

A collection device, electric vehicle technology, applied in the direction of measurement device, measurement of electricity, measurement of electric variables, etc., can solve the problems of reducing production takt, product qualification rate and reliability, troublesome after-sales maintenance of batteries, intricate wiring harness, etc., to improve production. Beat, improve product qualification rate and reliability, clear wiring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

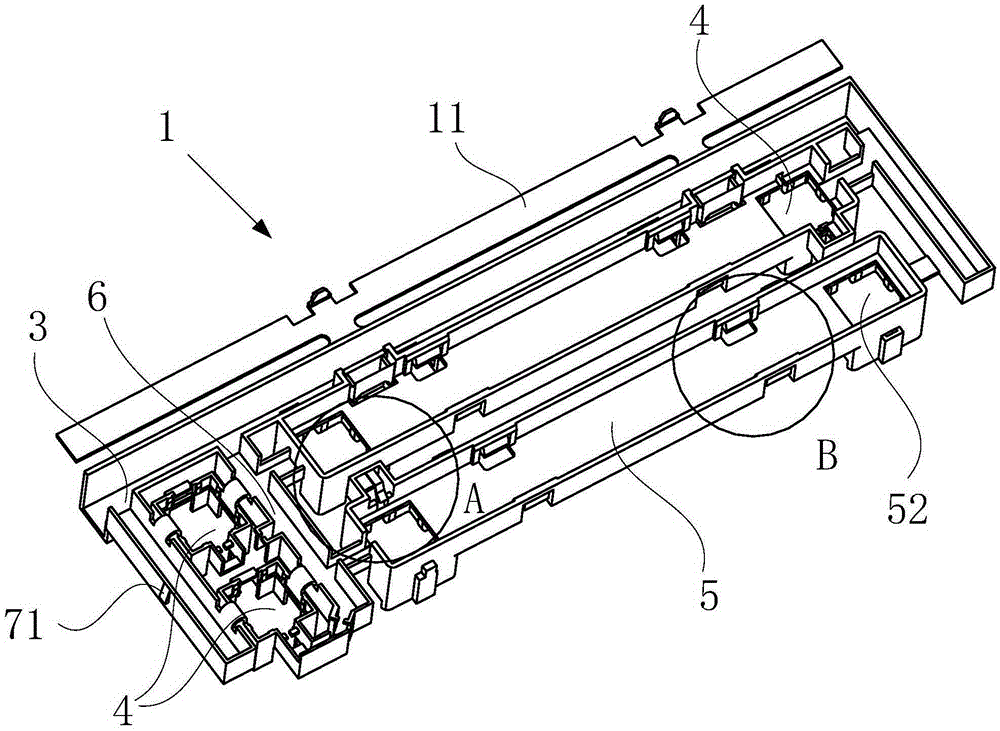

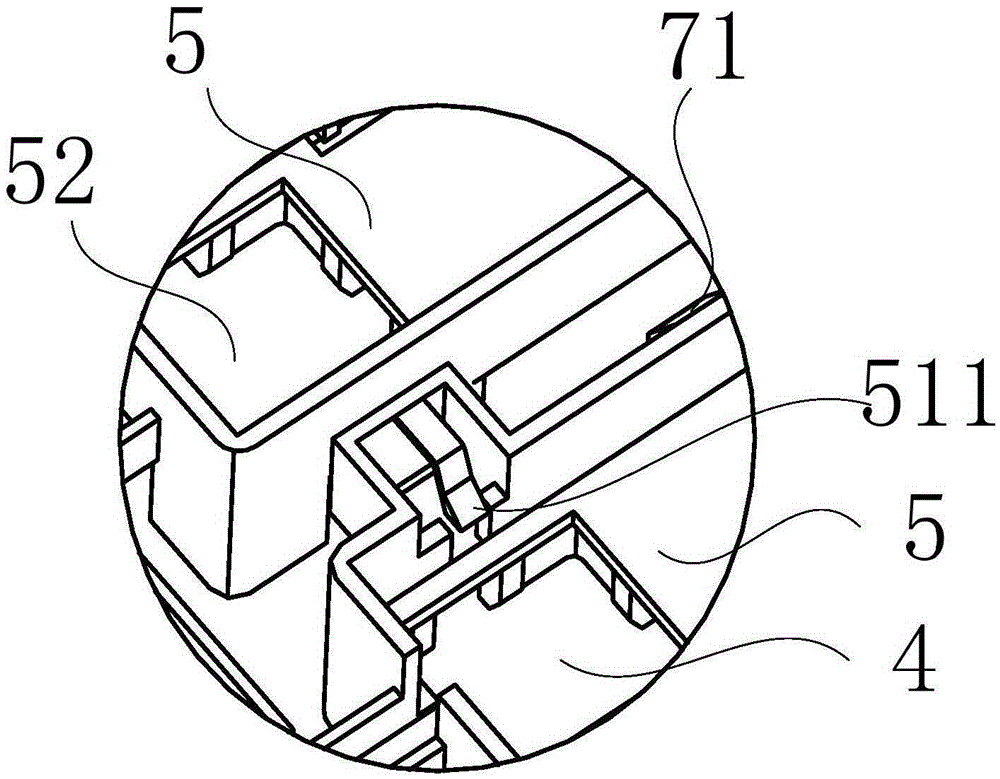

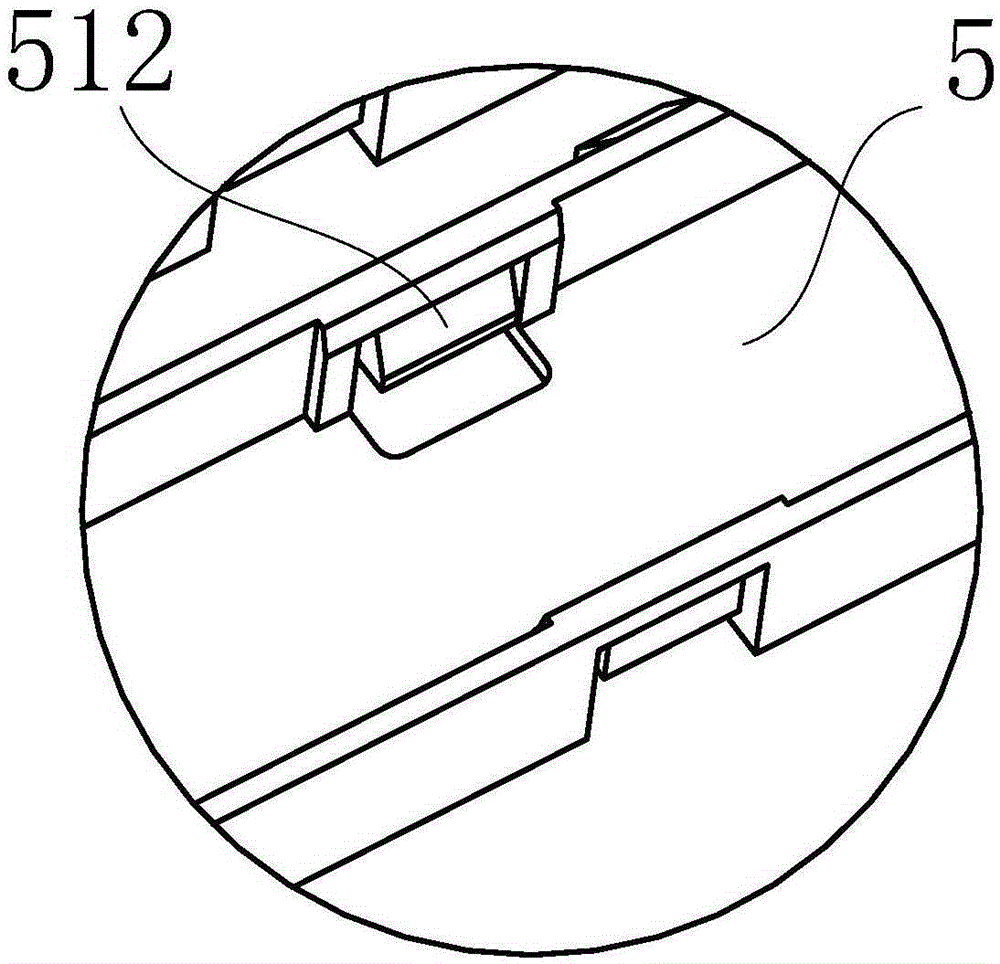

[0038] An embodiment of the present invention provides a battery collection device for an electric vehicle, such as figure 1 with Figure 5 shown, which includes:

[0039] The main housing 1, the plug-in 61, the collection wire harness 31 and m wire harness terminals 41, where m is an integer greater than 1;

[0040] The main housing 1 is provided with a plug-in installation groove 6, a wire harness groove 3 and at least m first limiting grooves 4, and the wire harness groove 3 is connected to each of the plug-in installing groove 6 and at least m first limiting grooves 4 respectively. A limiting groove 4 communicates;

[0041] The m wire harness terminals 41 are respectively arranged in the m first limiting grooves 4, the plug-in 61 is arranged in the plug-in installation groove 6, and each wire harness terminal 41 in the m wire harness terminals 41 is connected to the plug-in 61 through the collection wire harness 31, and The collection wire harness 31 is arranged in the ...

Embodiment 2

[0070] An embodiment of the present invention provides a battery system for an electric vehicle, including the battery collection device and a battery pack for an electric vehicle described in Embodiment 1;

[0071] Each harness terminal 41 on the battery collection device is connected to a measurement point on the battery pack.

[0072] The battery collection device in this embodiment is completely the same as the battery collection device in Embodiment 1, so the structure of the housing will not be described in detail in this embodiment.

[0073] In this embodiment, the battery collection device can assemble the battery collection device offline by installing the collection wire harness 31, wire harness terminal 41, copper bar 51 and plug-in 61 in a main housing 1, and the completed battery collection device can be directly assembled online. The acquisition device is directly assembled around the battery pack, which achieves the purpose of modular assembly and improves the p...

Embodiment 3

[0075] An embodiment of the present invention provides an electric vehicle, including the battery system of the electric vehicle described in the second embodiment.

[0076] In this embodiment, the battery system assembled in the electric vehicle is very convenient and fast during after-sales maintenance, and the battery collection device can be directly disassembled for maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com