Kelp knotter

A kelp knotter and kelp technology, applied in food science and other directions, can solve the problems of high labor cost, low knotting success rate, affecting product quality and output, etc., and achieve the effect of reasonable structure and high knotting success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

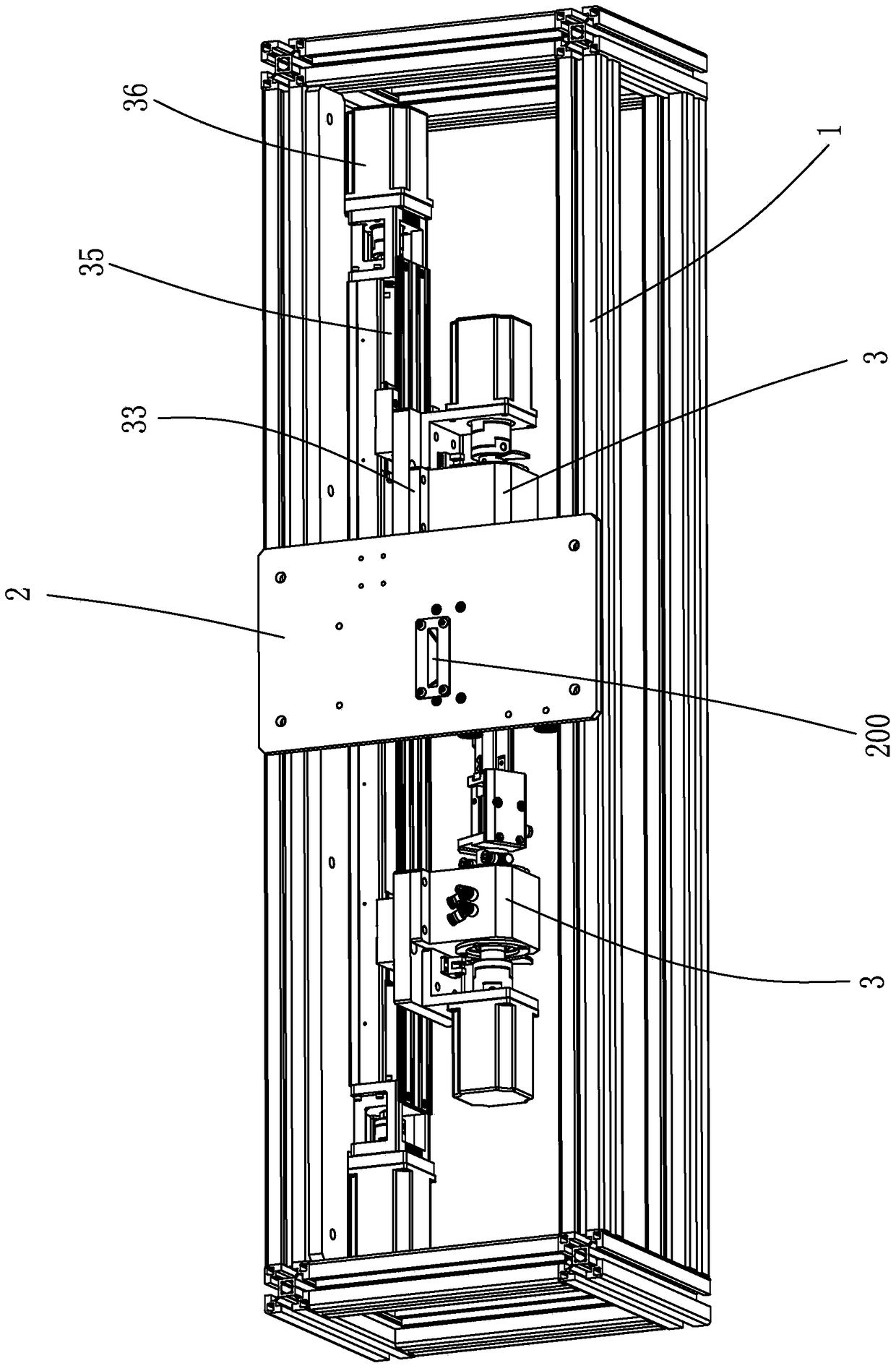

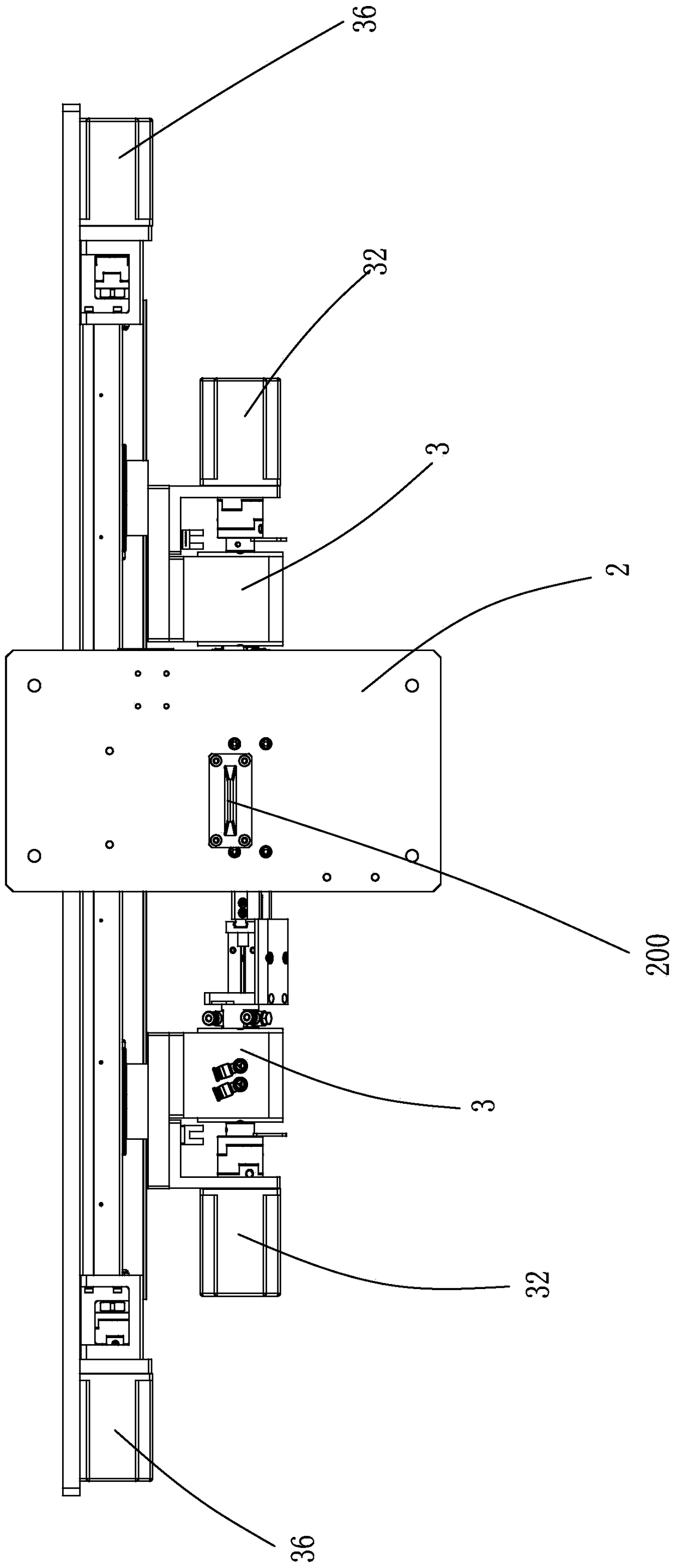

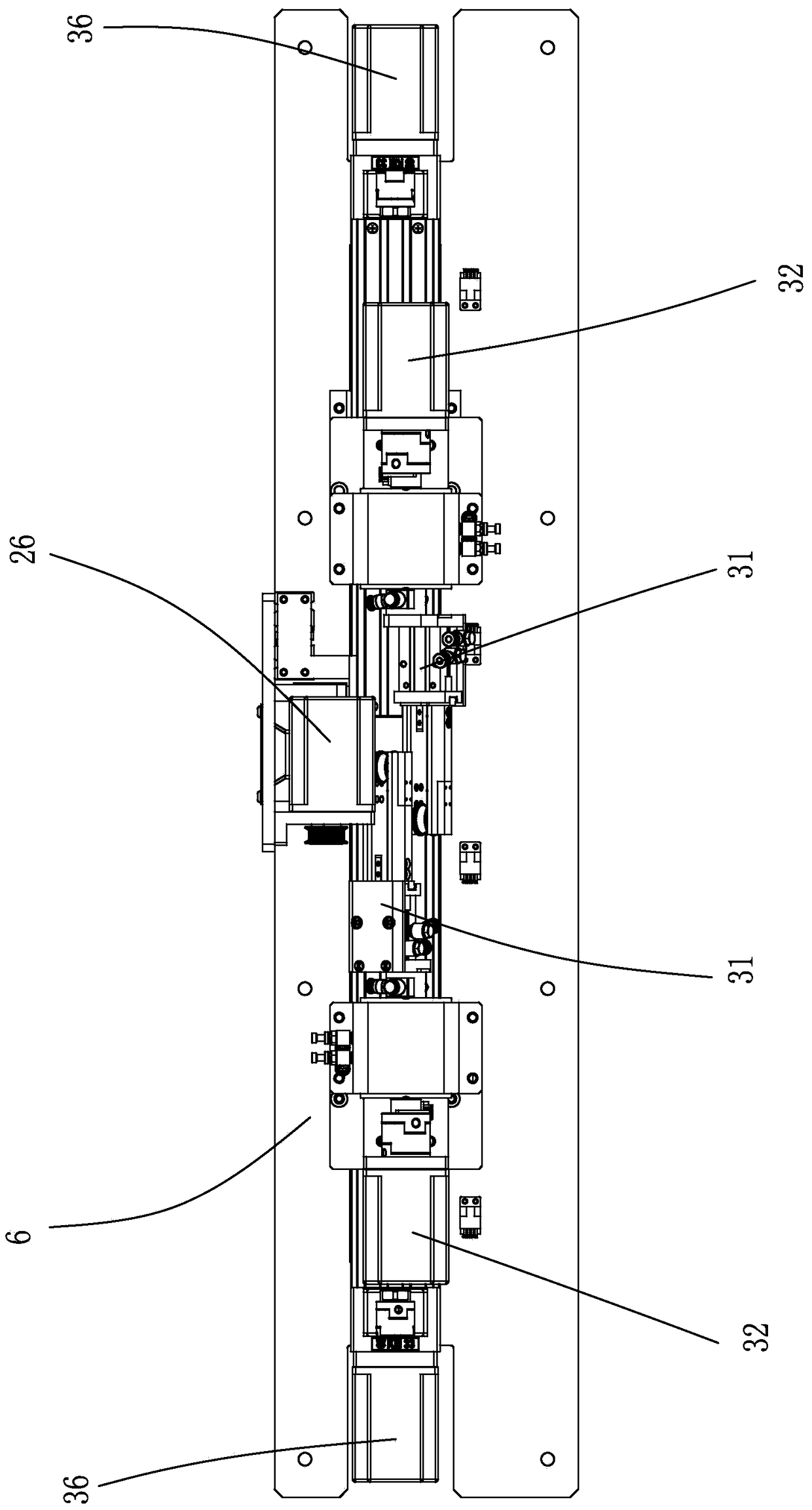

[0021] Example: see Figure 1 to Figure 5 , a kelp knotting machine, comprising a frame 1 and a feeding device 2 and a knotting device 3 installed thereon, said knotting devices 3 being two and symmetrically arranged on both sides of the feeding device 2, two dozen The knot device 3 can move back and forth along the linear guide rail 4 respectively, wherein:

[0022] Feeding device 2, which includes a feeding channel for conveying materials to be knotted;

[0023] Knotting device 3, it comprises eccentric pneumatic finger 31, rotary motor 32, slide 33, leading screw, linear motor and guide rail 4, described eccentric pneumatic finger 31 is connected with rotary motor 32 and performs eccentric rotation around motor shaft, rotates The motor 32 is installed on the sliding seat 33, and the sliding seat 33 cooperates with the guide rail 4 and the lead screw under the action of the linear motor to make the knotting device 3 reciprocate in a straight line. The eccentric pneumatic fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com