Automatic telescopic type head band structure

A technology of automatic telescopic and telescopic belts, which is applied to the fastening devices of head coverings, clothing, eye masks, etc., can solve the problems of uneven head size, increased mask damage, and high price, so as to meet safety requirements, Ease of fast protection and short wearing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

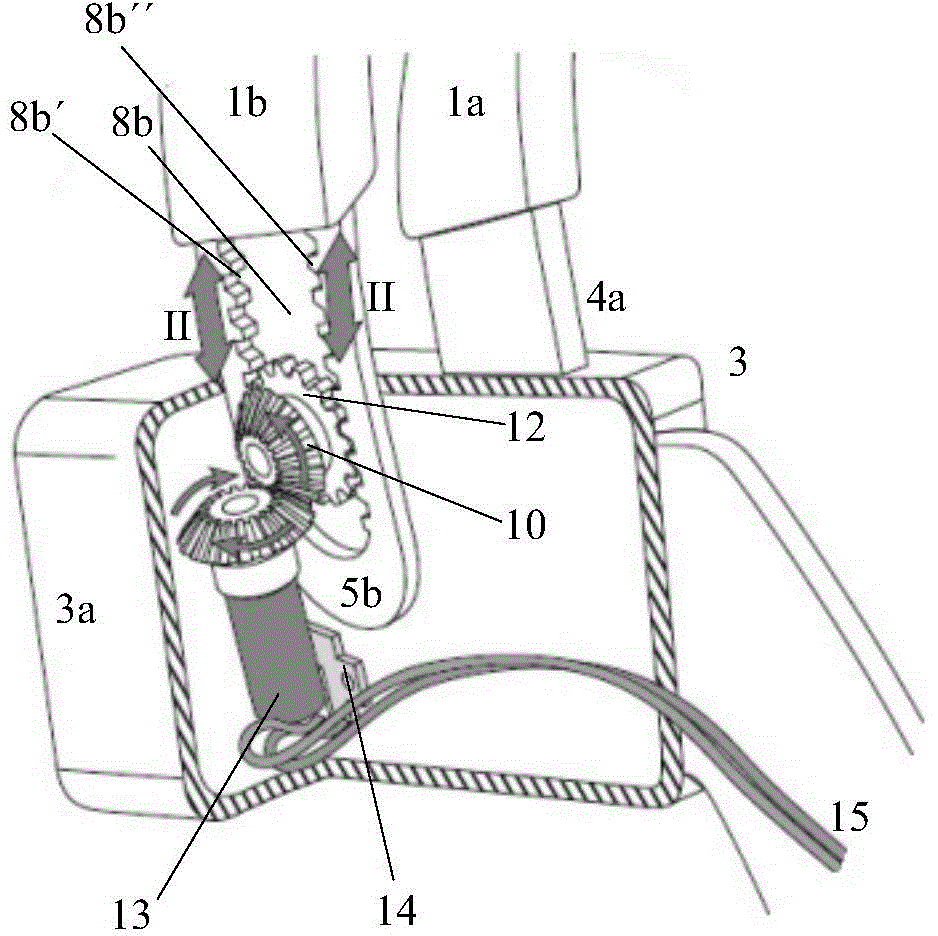

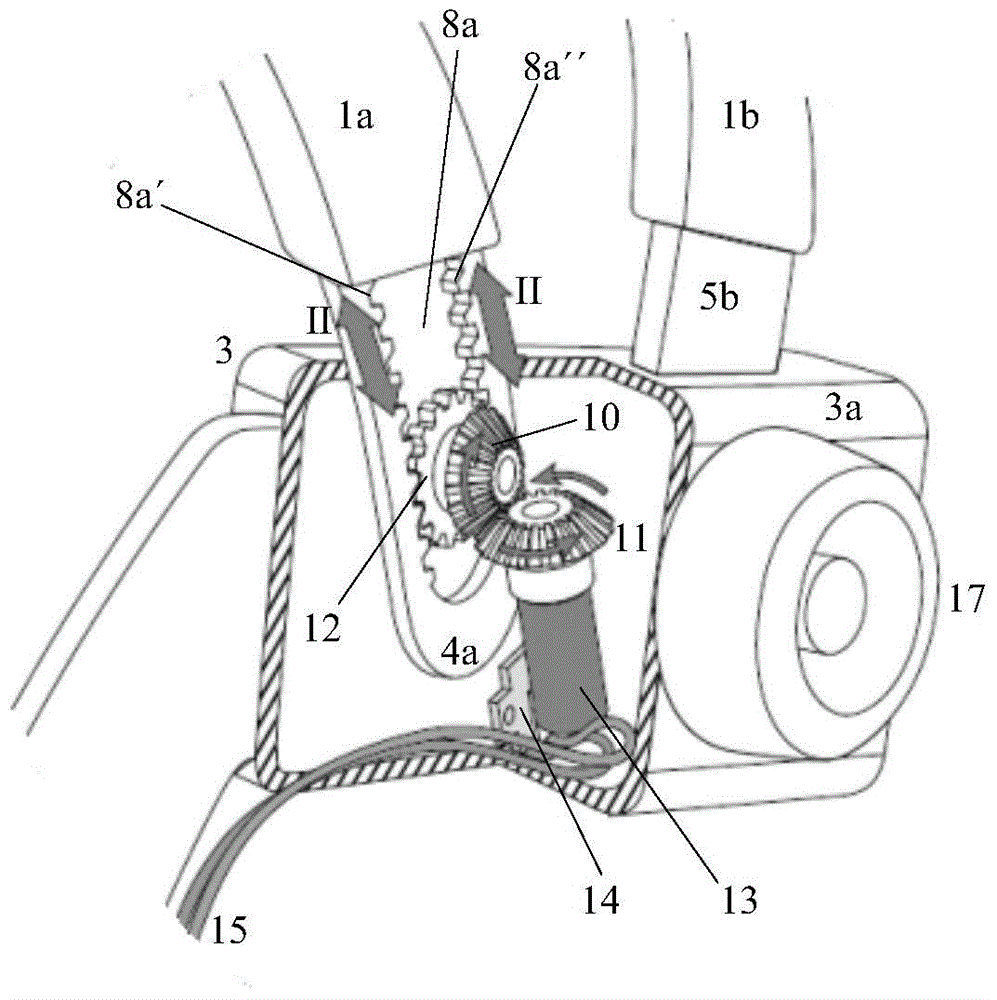

[0032] In the various figures of the application, structurally identical or functionally similar features are indicated by the same reference numerals.

[0033] The following content of the manual is only for the description of the headband structure of the mask. It should be apparent to those skilled in the art that the headgear structure of the present invention is suitable for application in any suitable mask, such as a welding mask. The headband structure is fixed on the inner liner of the mask, and the specific fixing method is based on any means known to those skilled in the art, and will not be repeated here.

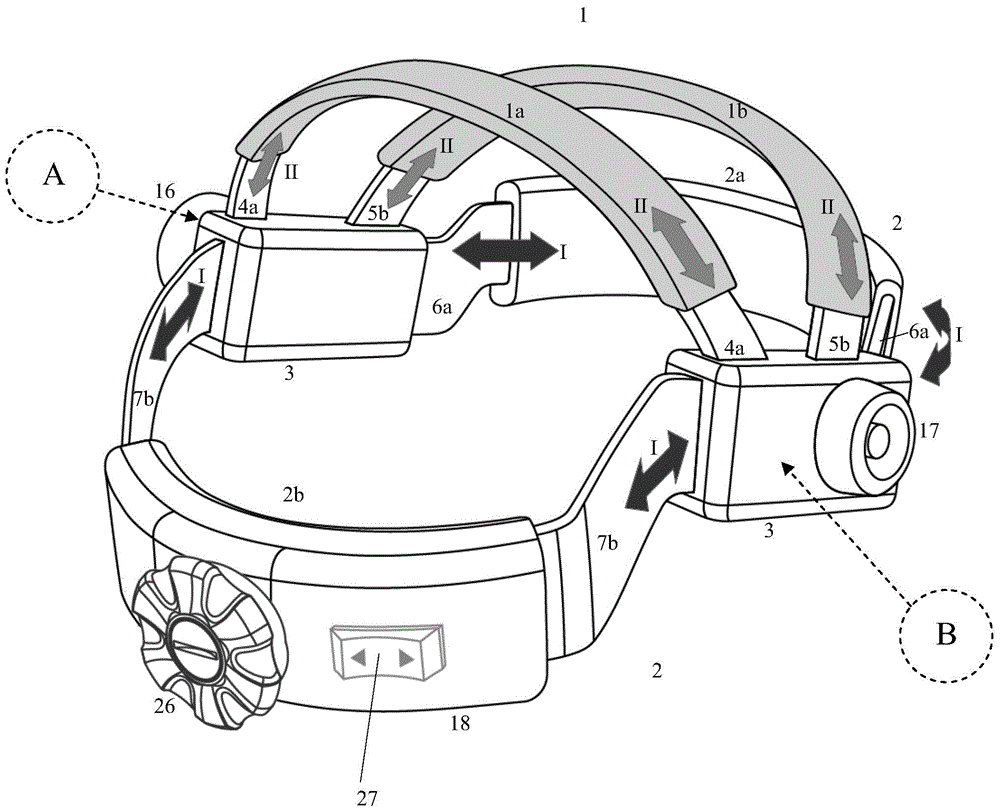

[0034] Such as figure 1 As shown, the headband structure generally includes a head restraint part 1 and a head circumference restraint part 2 . The head restraint part 1 is mainly used to provide the tightening force of the headband structure on the top of the wearer's head, while the head circumference restraint part 2 is mainly used to provide the tightening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com