Method for pipeline non-excavation restoration and reinforcement with light-cured fiber reinforced composite materials and pipeline

A technology for strengthening composite materials and composite materials, applied in the field of composite anti-corrosion and anti-seepage pipelines, can solve the problems of large curing impact, replacement of lines, and large reduction, and achieve the effect of no joint fluidity, extended service life, and rapid repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

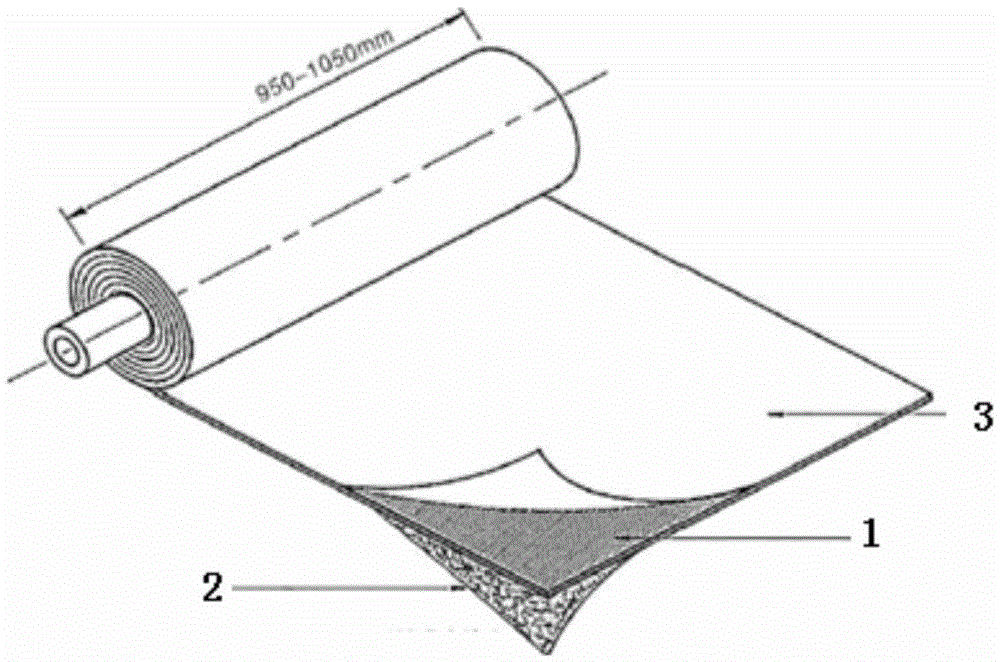

[0096] Embodiment 1: vertical closed pasting method (see figure 2 ).

[0097] Step 1: UV-cured fiber reinforced composite materials are bonded before construction, and the moisture on the inner wall of the pipe is wiped dry with a moisture-absorbing dry cloth.

[0098] Step 2: First peel off one end of the protective film 2 on the sticking surface of the light-cured fiber reinforced composite material, and then carefully paste the peeled side on the inner wall of the pipe. Segmented vertical coating, the sequence of the first segment can start from the counterclockwise (clockwise) direction of the 5 o'clock (or 7 o'clock) position of the clock corresponding to the cross section of the pipe, wrap around the top of the pipe, and continue to attach to the joint. Seam position, tear off 3 seams of the top layer of film, and overlap the two ends of the composite material. There should be a lap length of 8-10cm or 30-50mm at the lap peak, and roll the lap seam forcefully with hand...

Embodiment 2

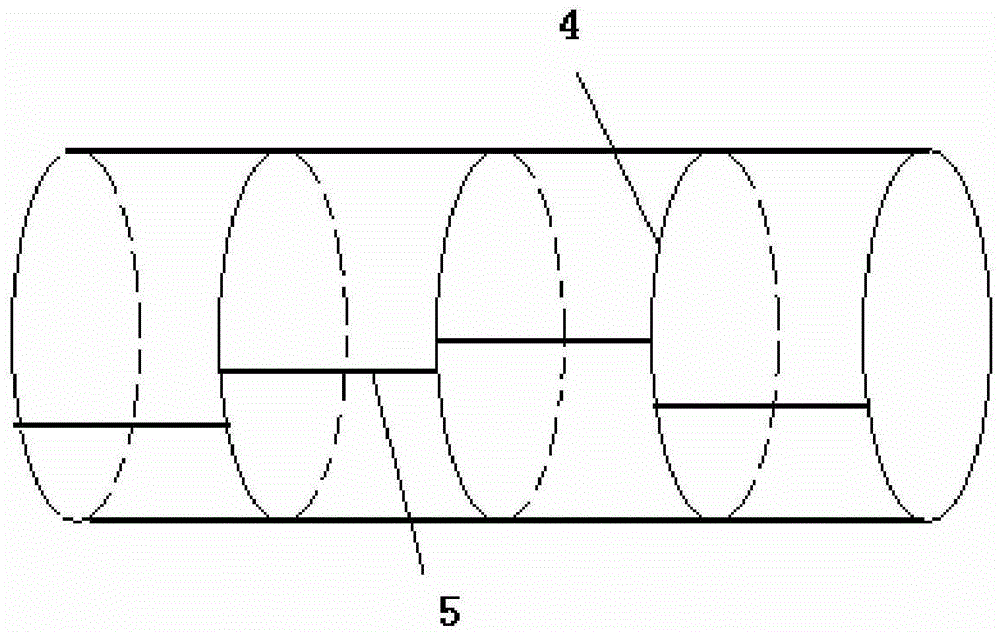

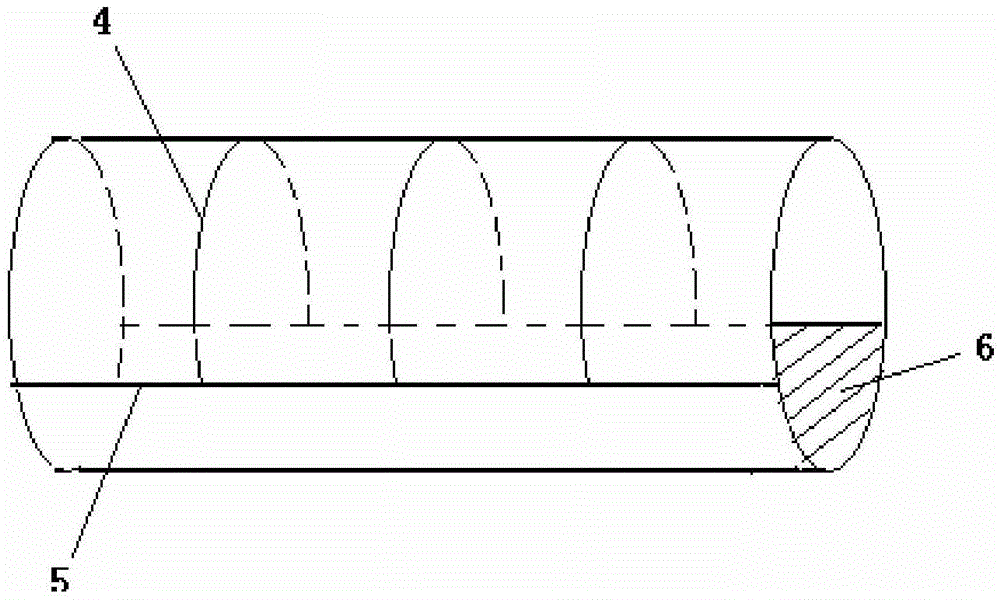

[0108] Embodiment 2: the law of pasting of reserved working channel (see image 3 ).

[0109] In order to prevent the newly pasted anti-corrosion reinforcement patch at the bottom of the pipeline from being damaged by transport vehicles and workers walking during the construction process, the thickness of each sheet is calculated according to the diameter and length of the pipeline under the condition that the 1-meter-wide inner wall at the bottom of the pipeline is not pasted temporarily. Length and width, paste the composite material of the set length and width on the upper peripheral wall of the pipe in an arc range above, and reserve the inner wall with a chord length of one meter at the bottom of the pipe for the time being, and then take another section The composite material with a set width is pasted on the circumferential wall of the pipe along the same arc range in the axial direction, and the inner wall of the pipe with a chord length of less than one meter is reser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Chord length | aaaaa | aaaaa |

| Overlap length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com