Rapid clamping device for pipeline cleaning machine

A pipeline cleaning and clamping device technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the corrosion of screw rods and guide rods, is not suitable for cleaning large batches of pipe fittings, cleaning liquid spraying Reliable and stable clamping force can be achieved without problems such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

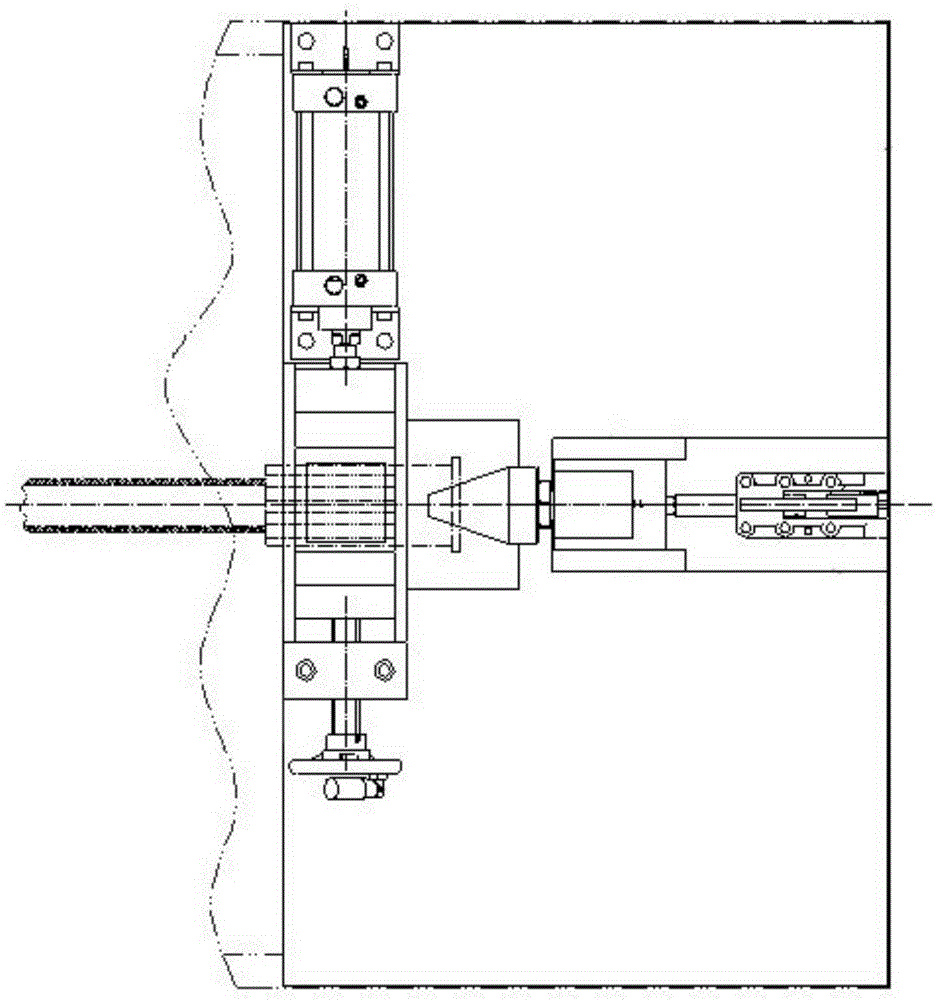

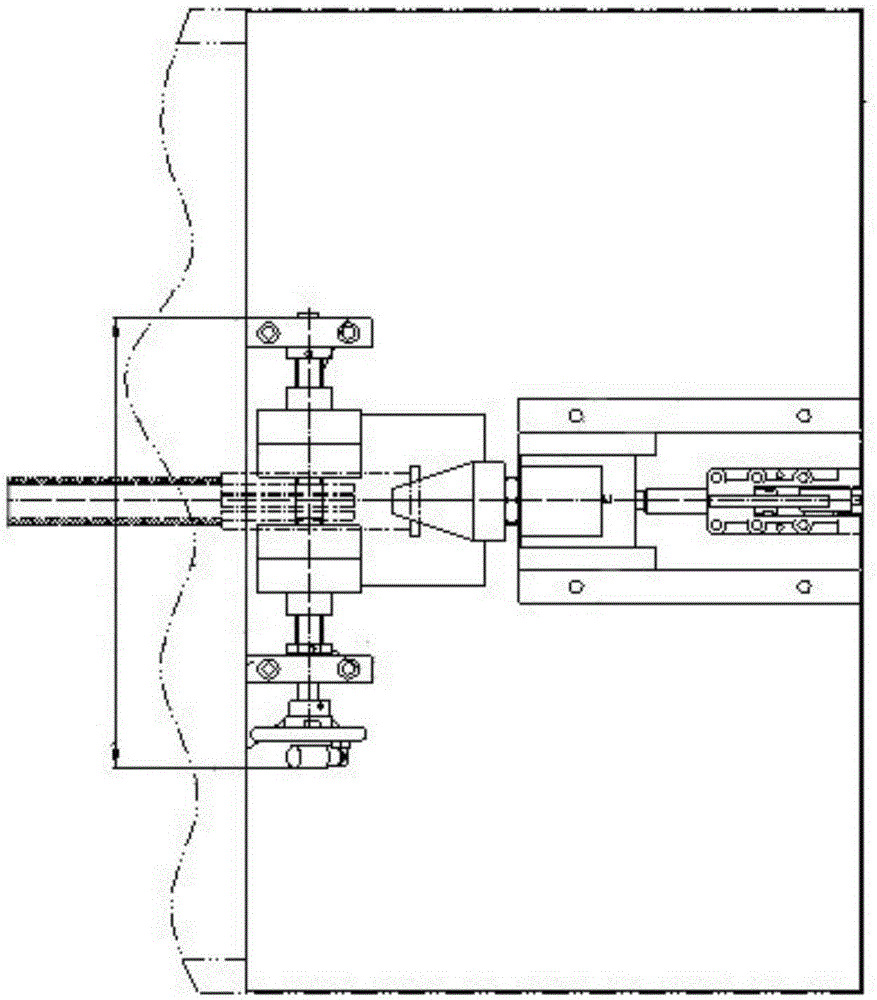

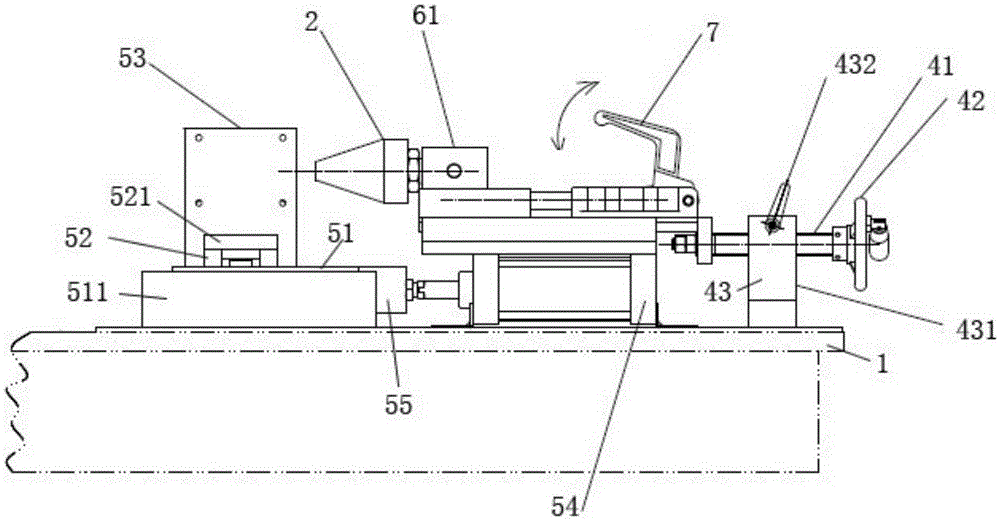

[0023] refer to Figure 3 ~ Figure 5 , the quick clamping device of the pipeline cleaning machine in this embodiment includes a base plate 1, a nozzle 2, a pipe fitting 3, a pipe fitting clamping assembly, a nozzle sliding assembly and a quick clamp 7, a pipe fitting clamping assembly is arranged on the bottom plate, and the pipe fitting clamping A pipe fitting 3 is arranged on the assembly, and a nozzle 2 is arranged on one side of the pipe fitting clamping assembly, and the nozzle 2 is fixed on the nozzle sliding group, and also includes a nozzle adjustment assembly and a clamp sliding assembly, and the nozzle adjustment assembly includes an adjustment screw 41 and adjustment Hand wheel 42, the clamp slide assembly includes clamp slide 81 and clamp slide rail 82, the quick clamp 5 and nozzle slide assembly are installed on the clamp slide 81, clamp slide 81 is installed on In the clamp slide rail 82 , one end of the adjusting screw rod 41 is fixedly connected with the clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com