Rotary drilling processing control system of cylinder cover of diesel engine

A control system and cylinder head technology, applied in metal processing, boring/drilling, automatic control devices, etc., can solve problems such as time-consuming and labor-intensive, affecting the machining accuracy and position accuracy of each hole, and affecting the performance of the diesel engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

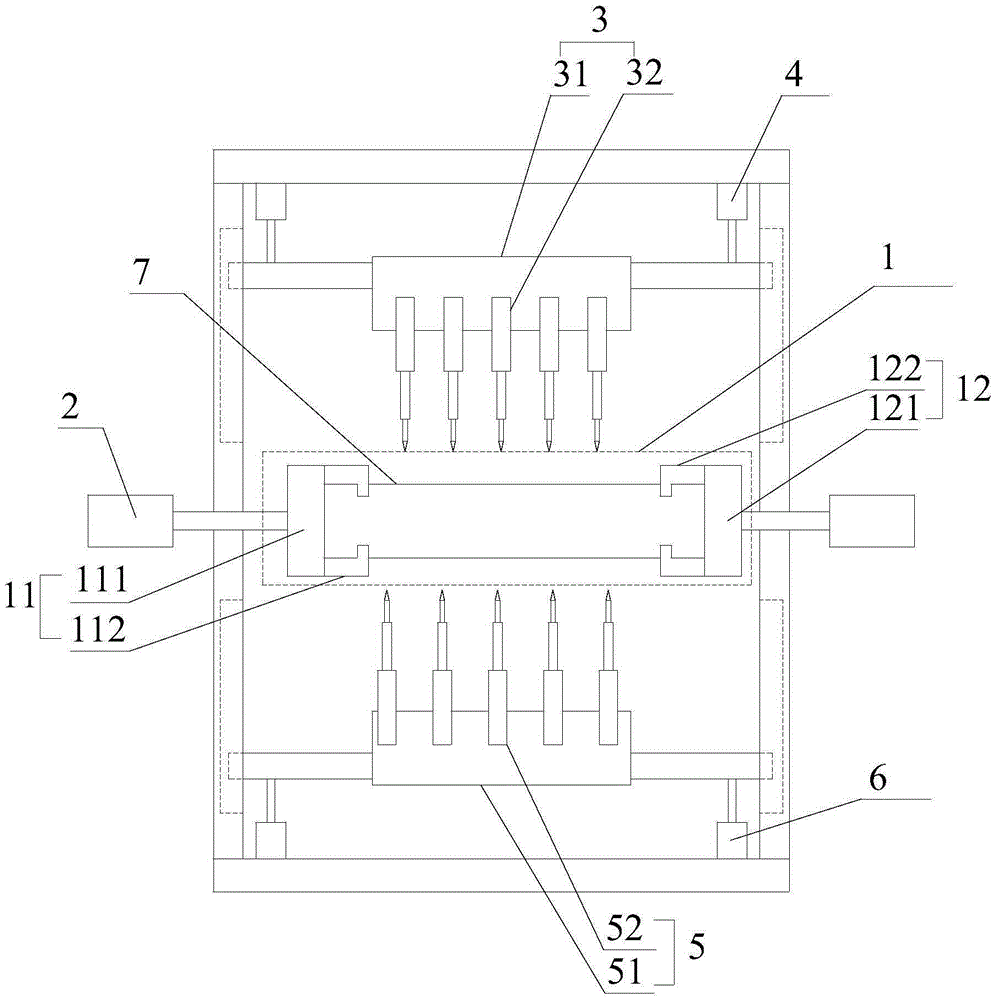

[0019] refer to figure 1 , figure 2 , image 3 , the present invention proposes a diesel engine cylinder head rotary drilling processing control system, including a cylinder head fixing device 1, a first driving device 2, a first drilling device 3, a second driving device 4, a second drilling device 5, a second Three driving devices 6, a first distance measuring sensor, a second distance measuring sensor and a control device, wherein:

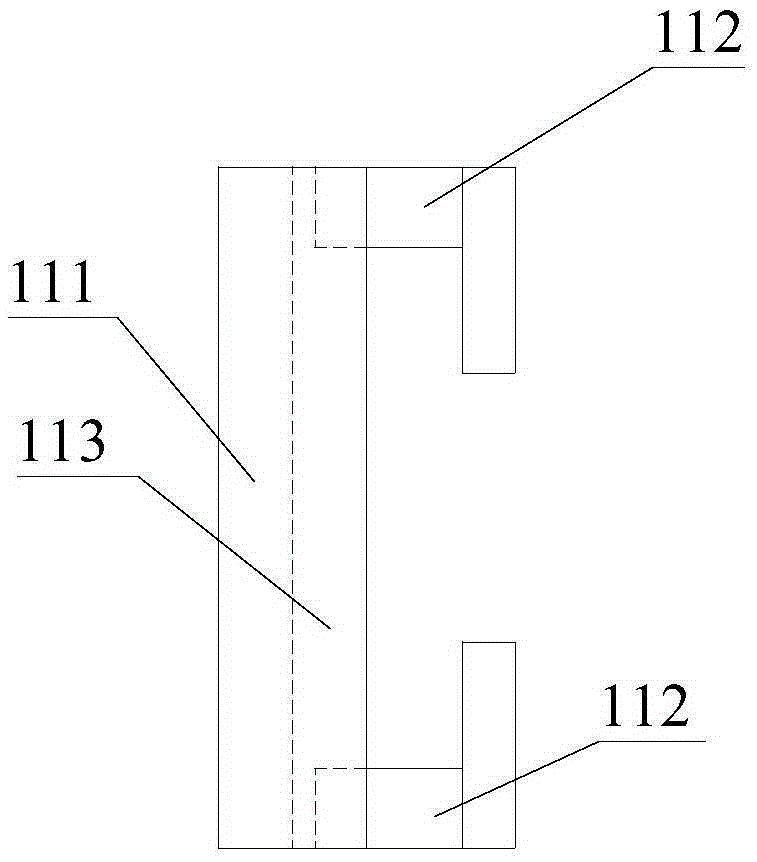

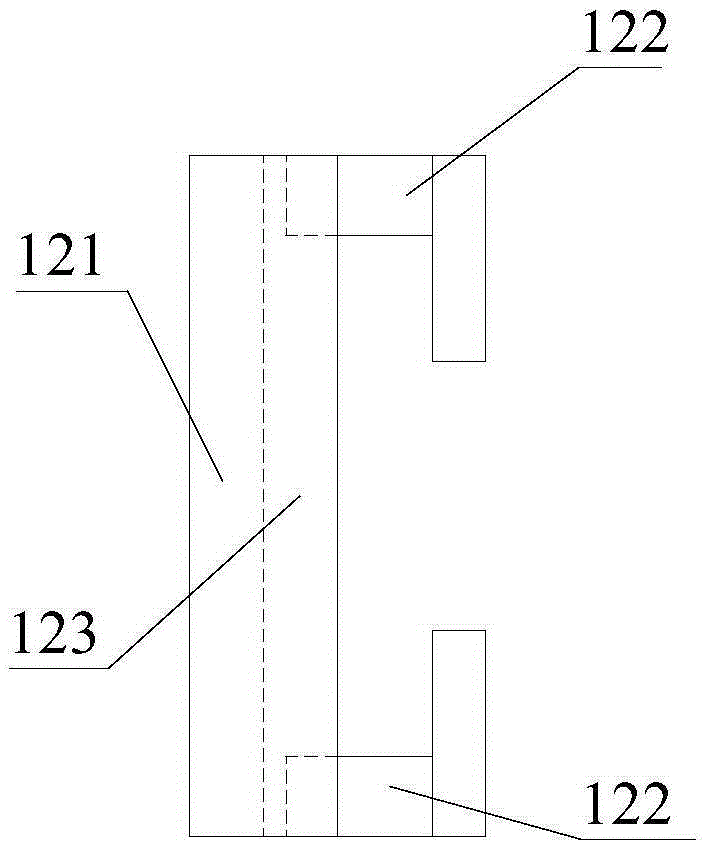

[0020] The cylinder head fixing device 1 is used for fixing the cylinder head 7 . The cylinder head fixing device 1 includes a first fixing unit 11 and a second fixing unit 12 arranged side by side along the horizontal direction. As for the fixing part, the cylinder head 7 is axially fixed by cooperating with the first fixing part on the first fixing unit 11 and the second fixing part on the second fixing unit 12 . The first fixing unit 11 also includes a first base 111, the first fixing part includes two first clamping heads 112, the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com