Forward and reverse automatic detachable drill pipe for mining

An automatic disassembly, forward and reverse technology, applied in the direction of drill pipe, drill pipe, earthwork drilling, etc., can solve the problems that cannot meet the operation requirements of automatic drilling rigs, require manual cooperation, and cannot realize automatic disassembly of drilling rigs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

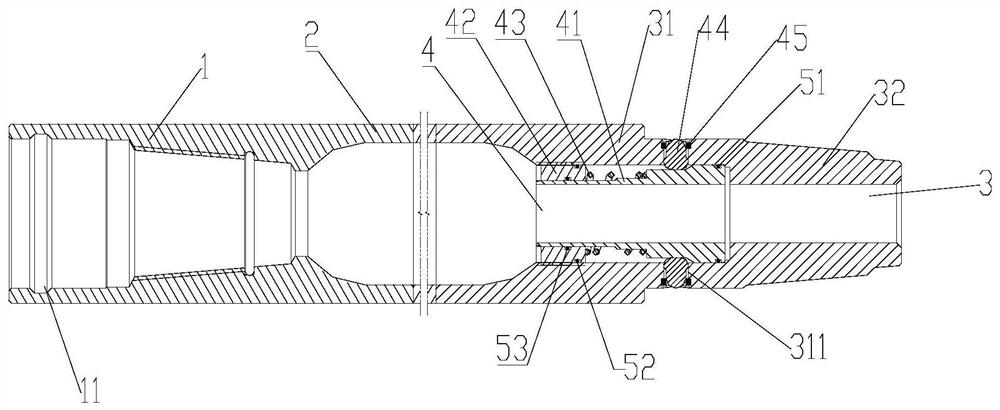

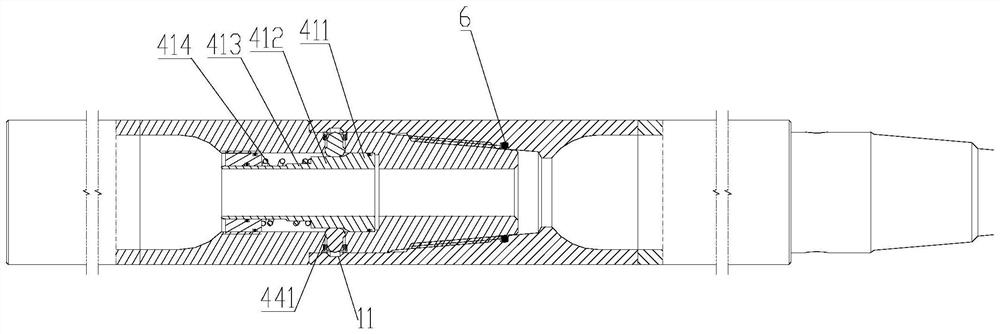

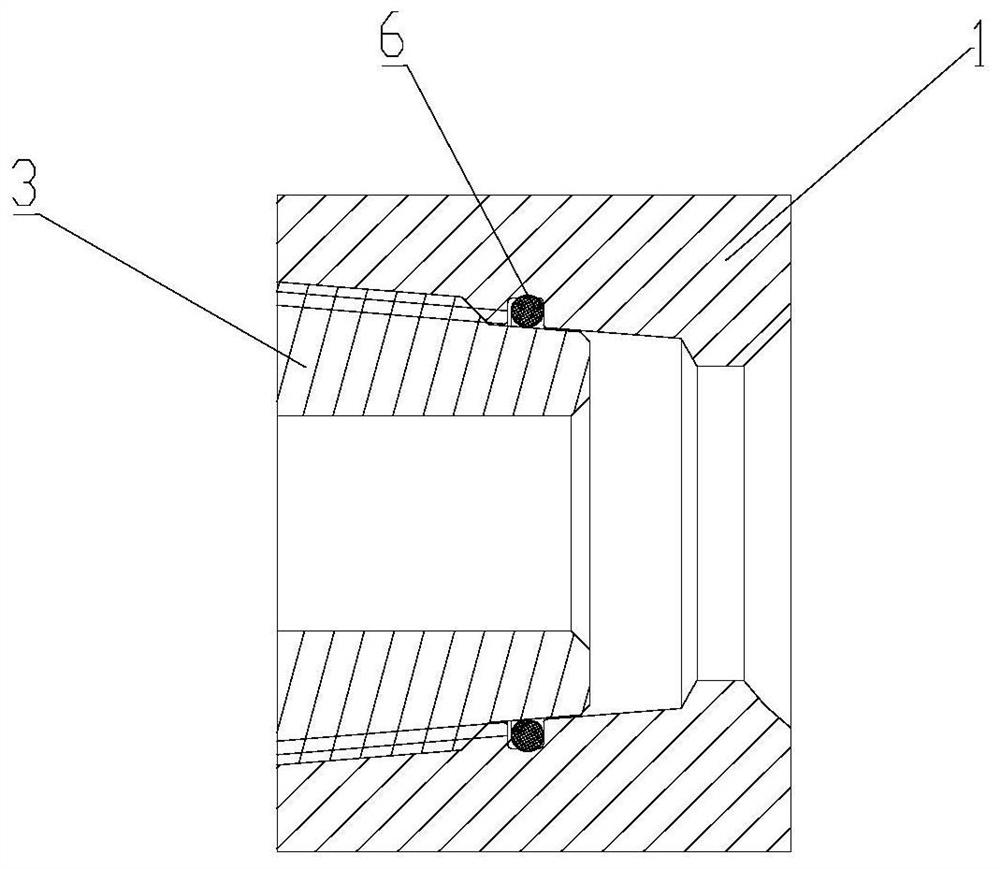

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the connection structure of the male and female joints of the present invention, image 3 It is an enlarged view of the first sealing ring. As shown in the figure, the mine-used forward and reverse automatic detachable drill pipe in this embodiment includes no less than one drill pipe unit that can be connected in sequence, and the drill pipe unit includes The female joint 1, the pipe body 2 and the male joint 3 are connected in sequence. The two adjacent connected drill pipe units are detachably connected through the cooperation of the male joint 3 and the female joint 1. The male joint 3 includes a hollow hole forming a stepped hole. The control section 31 and the introduction section 32, and the inner diameter of the control section 31 is larger than the inner diameter of the introduction section 32, and a jacking mechanism 4 is arranged in the hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com