An electronic product assembly line

A technology for assembling production lines and electronic products, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult line, low efficiency, large site area, etc., to achieve flexible adaptability, improve transmission accuracy, The effect of preventing the belt from slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

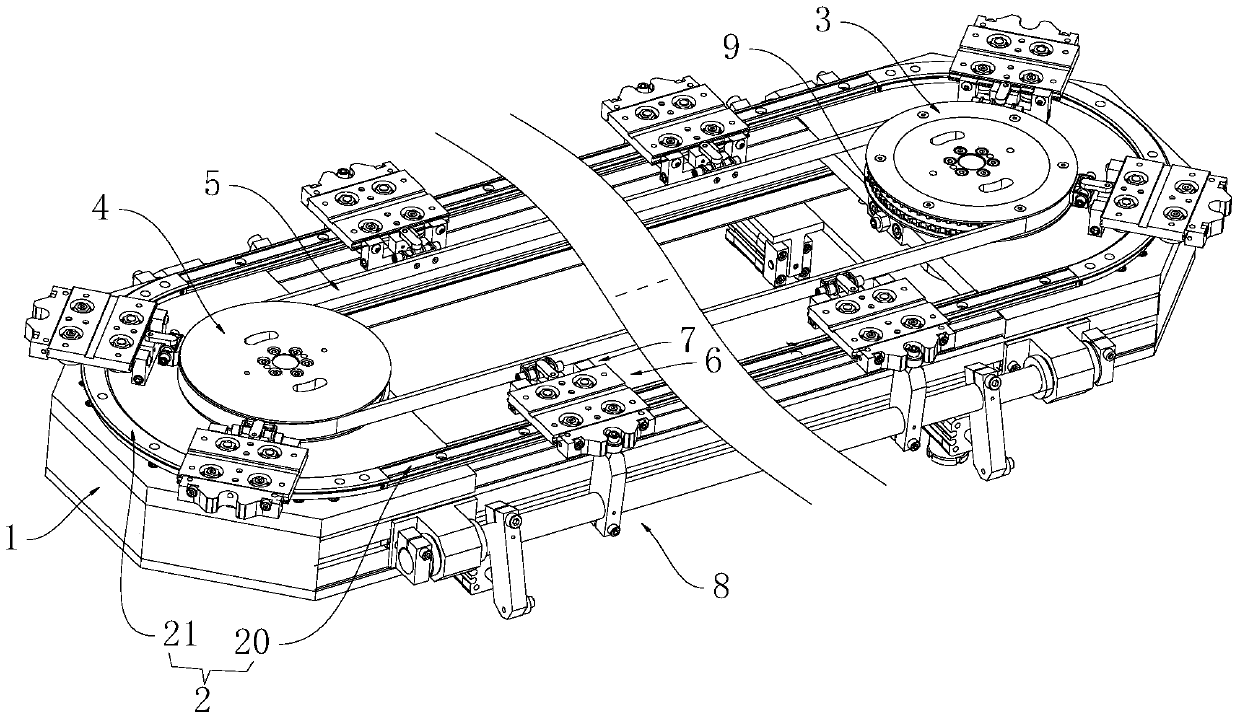

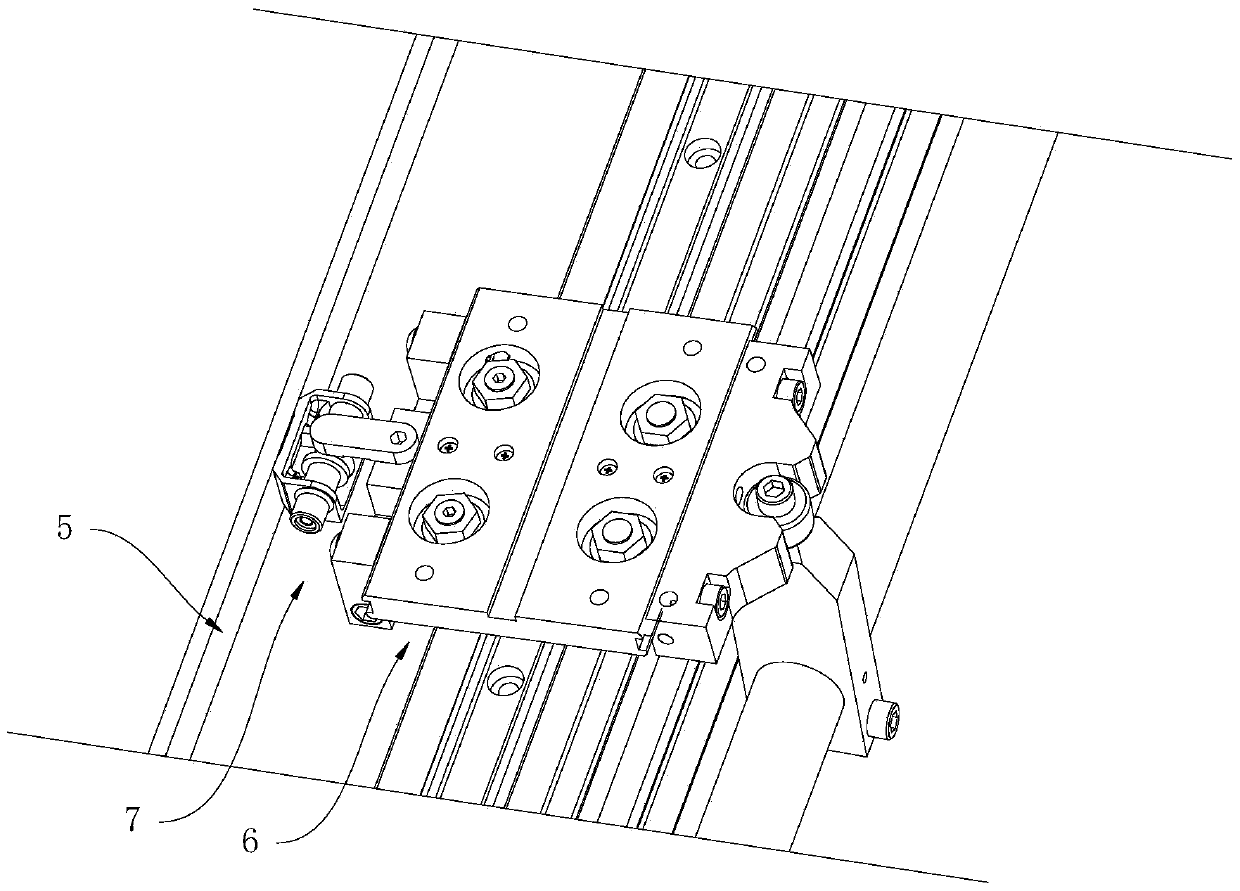

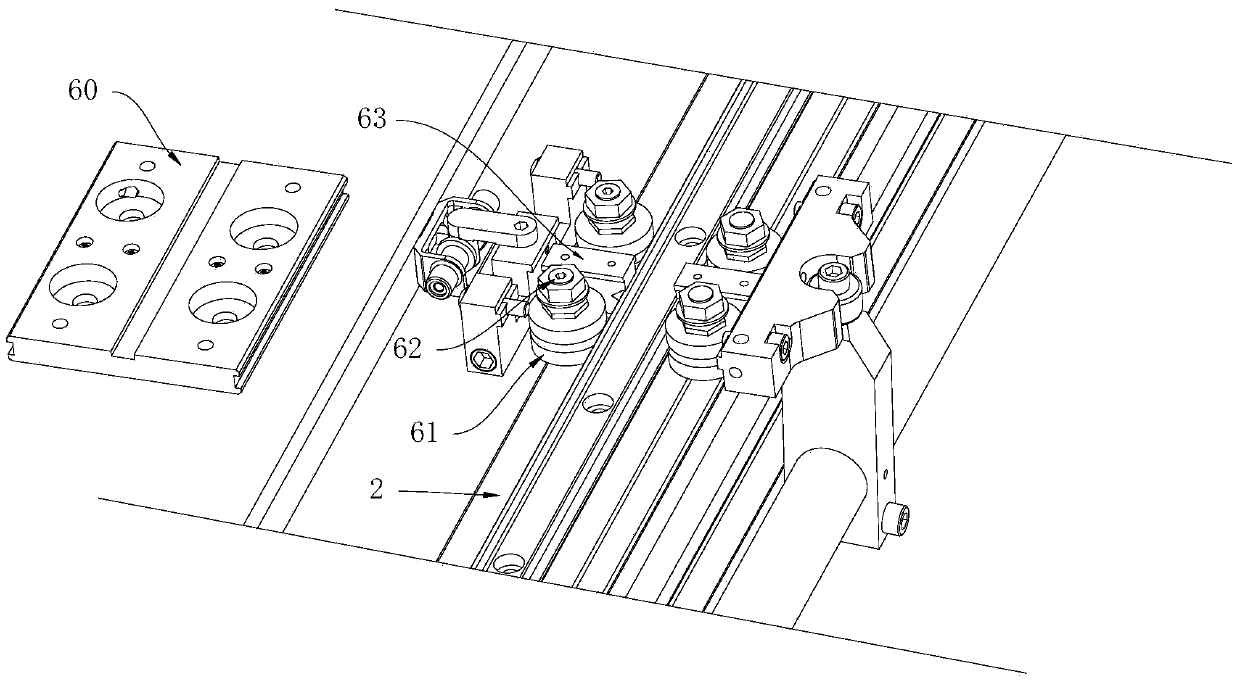

[0022] The invention discloses an electronic product assembly production line, which combines Figure 1 to Figure 7 As shown, it includes a frame 1, and the frame 1 is provided with a slide rail 2, and the slide rail 2 includes two linear guide rails 20 and two arc guide rails 21, and the two linear guide rails 20 are arranged in parallel, Two arc guide rails 21 are separately arranged at two ends of two linear guide rails 20 so that the slide rail 2 is in the shape of a racetrack. The inside of the slide rail 2 is provided with a driving wheel 3 and a driven wheel 4, and the driving wheel 3 and the driven wheel 4 is connected by a belt 5, and a preset distance is maintained between the belt 5 and the slide rail 2, and a plurality of slider assemblies 6 are arranged on the slide rail 2, and the slider assemblies 6 and the belt 5 pass through a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com