Quick-bonding pre-stress steel strand, and inducer and preparation method of the inducer

A bonding prestressing and slow bonding prestressing technology, applied in the direction of structural elements, building components, buildings, etc., can solve the problems of insufficient tension, failure to meet the requirements of mechanical performance indicators, and inability to stretch, reducing Constraining, stabilizing and controllable performance indicators, ensuring the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

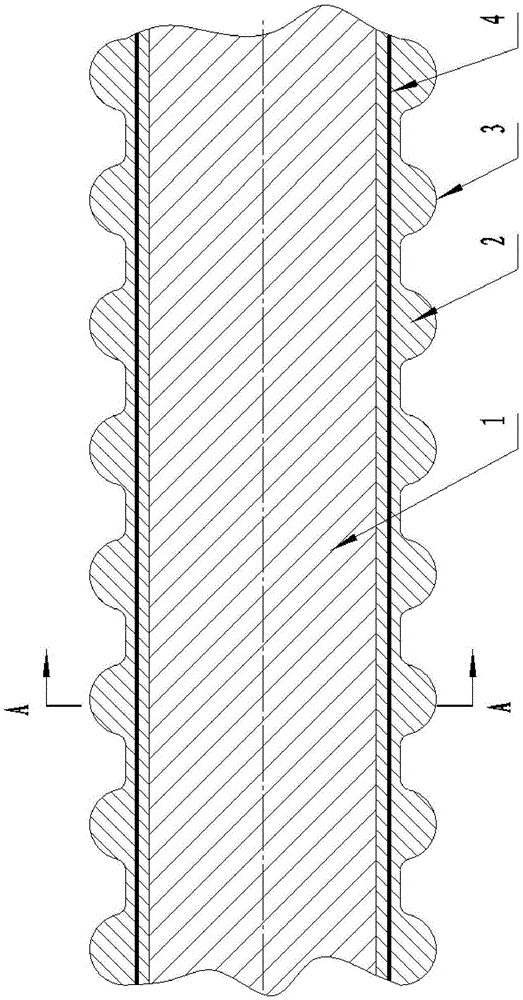

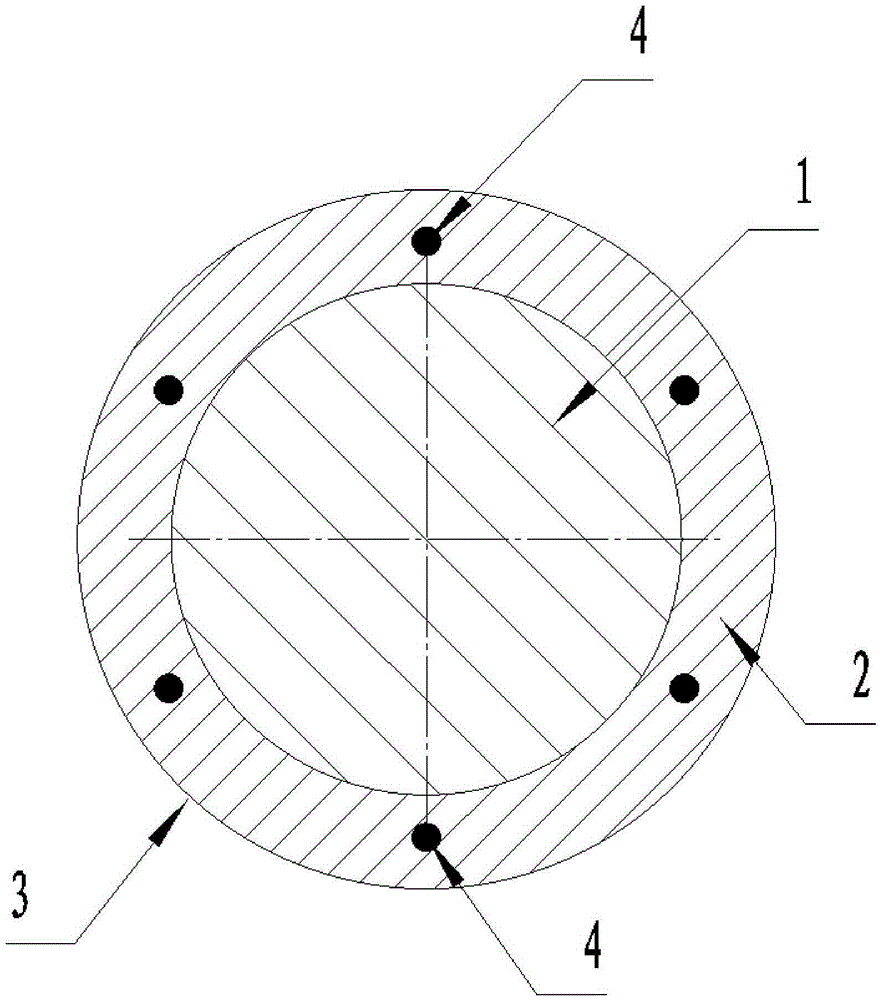

[0039] A quick-bonded prestressed steel strand, comprising: a steel strand 1 and a sheath 3 set outside the steel strand 1, and a solidified liquid gel is filled between the steel strand 1 and the sheath 3 Material layer 2, the steel strand 1 is provided with an inducer 4 for accelerating the curing of the cementitious material layer 2, such as figure 1 and figure 2 shown.

[0040] In this embodiment, the inducer 4 can be arranged in the gel material layer 2 or the sheath 3, and the material of the gel material layer 2 is epoxy resin adhesive. The sheath 3 is bellows-shaped, the wall thickness of the sheath 3 is uniform, the side wall of the sheath 3 contains continuous concave parts and convex parts, and the distance between the inner surface of the concave part of the sheath 3 and the outer surface of the steel strand 1 0.1 mm to 0.5 mm, and the outer diameter of the convex portion of the sheath 3 is 1.5 mm to 2.5 mm larger than the outer diameter of the concave portion o...

Embodiment 2

[0048] This embodiment is an alternative to Embodiment 1, and Embodiment 1 and Embodiment 2 are in a parallel relationship.

[0049] In this embodiment, only the inducer 4 is different from Embodiment 1, and the rest of the technical features can be the same, that is, the quick-bonded prestressed steel strand in this embodiment and the quick-bonded prestressed steel strand in Embodiment 1 The lines differ only in inducer 4.

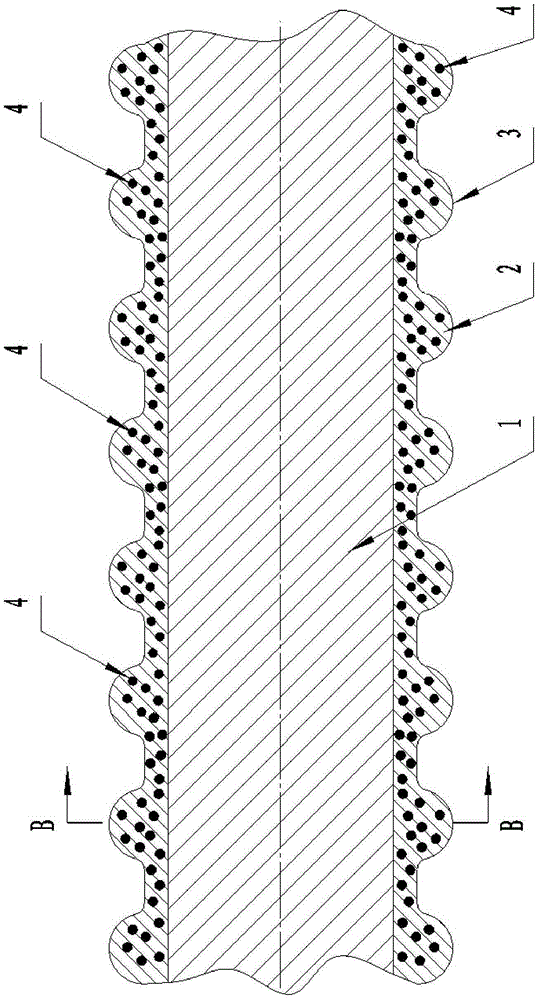

[0050] An inducer 4, the inducer 4 is a microcapsule-type inducer 4, the inducer 4 is a plurality of microcapsules arranged in the gel material layer 2, the microcapsules include a closed shell and a content, the The content is a curing accelerator that can accelerate the curing of the gelling material layer 2, and the microcapsules can be ruptured after the quick-bonding prestressed steel strand is stretched and the content is flowed out, such as image 3 and Figure 4 shown.

[0051] In this embodiment, the diameter of the microcapsule is 10 μm to 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com