Anti-outburst structure of packer rubber tube

A technology of packers and rubber cartridges, which is applied in the field of anti-outburst structure of packer rubber cartridges, which can solve the problems of spring stuck to casing and top shoe, insufficient pressure bearing capacity of rubber cartridges, and limited use range, etc., to achieve pressure bearing The effect of capacity improvement, reliable performance and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

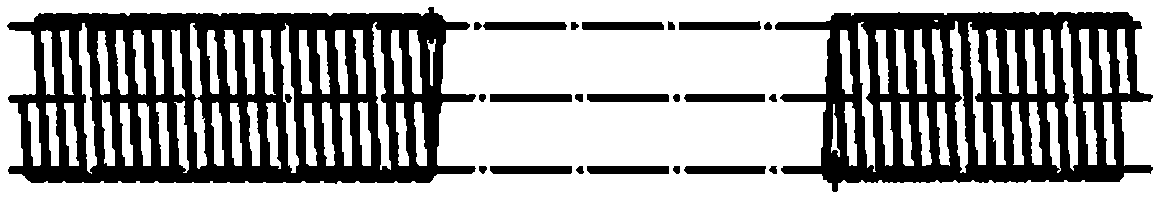

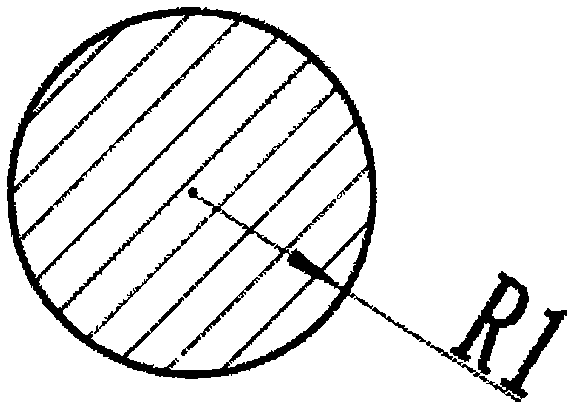

[0030] Such as figure 1 Shown is a schematic diagram of the helical tension spring before processing in the present invention. Cut the helical tension spring to a certain length, and repair and twist the two ends of the spring wire, so that the end and the end can be connected to form a complete ring. The inner radius of the helical tension spring is R1, and the diameter is 2×R1.

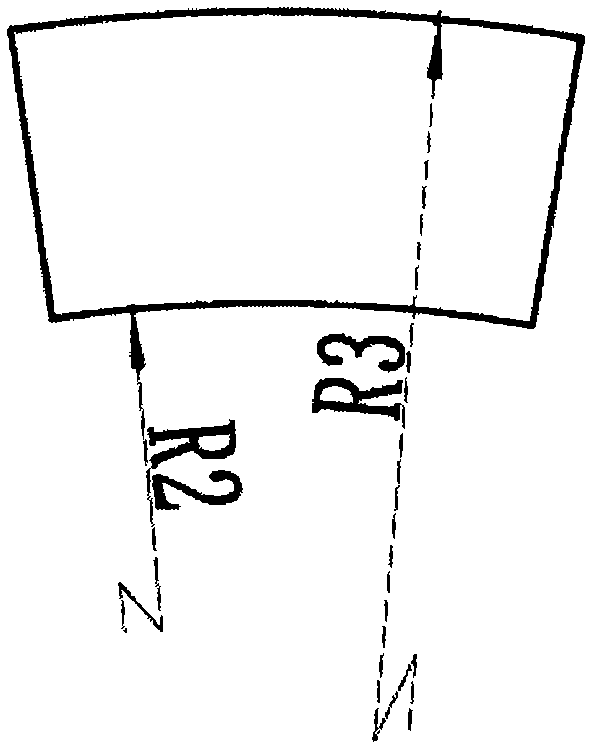

[0031] Such as Figure 2 ~ Figure 3 Shown is a front view and a schematic cross-sectional view of the filling block of the present invention. The filling small piece is an inwardly curved arc rod small piece, and its diameter is consistent with or matches the inner diameter of the spring 1 . The outer arc radius is the sum of its diameter and the inner arc radius R2 of the filling ring 2, and is consistent with the outer arc radius R3 of the filling ring 2, that is, R3=2×R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com