Jaw vice anchorage anchor device used for single-hole steel strand fatigue test

A fatigue test and anchoring device technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of time-consuming and laborious manual operation, fracture of the engagement part of the clip, failure of fatigue test, etc., and achieves improved assembly efficiency and adjustable assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

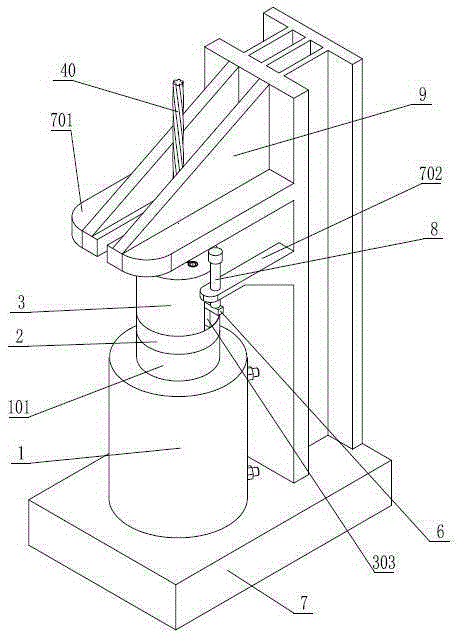

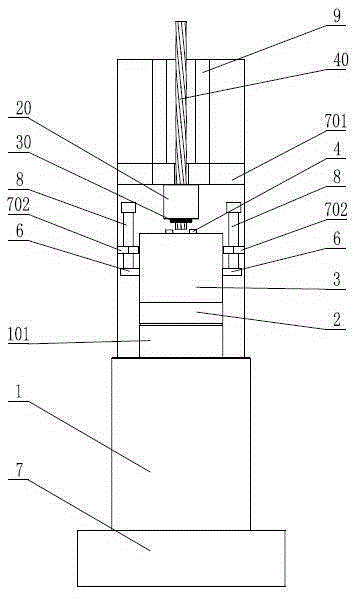

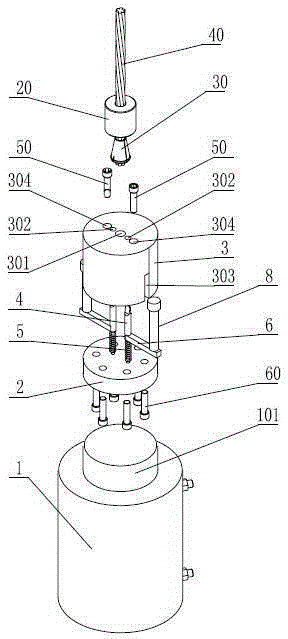

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0023] See figure 1 , figure 2 , image 3 , the anchoring device of the clip type anchor for single-hole steel strand fatigue test of the present invention comprises a vertical oil cylinder 1, a fixed plate 2 is fixedly connected above the piston rod 101 of the oil cylinder 1, and the fixed plate 2 is connected with the fastening bolt 60 above the fixed plate 2. The pressure plate 3 is fixedly connected, and the upper end surface of the pressure plate 3 is provided with a central circular hole 301 and at least two installation holes 302. Each installation hole 302 is evenly distributed along the circumference of the circle centered on the center of the central circular hole 301. The central circular hole 301 is used to accommodate the single-hole steel strand 40; the lower part of the pressure plate 3 is provided with a radial opening g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com