Motor carbon brush assembly with stable brush pressure

A carbon brush and component technology, applied in electrical components, motor generator connectors, circuits, etc., can solve the problems of rising motor current value, easy generation of sparks, and unstable current, so as to avoid excessive wear of carbon brushes and reduce sparks. The effect of producing and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

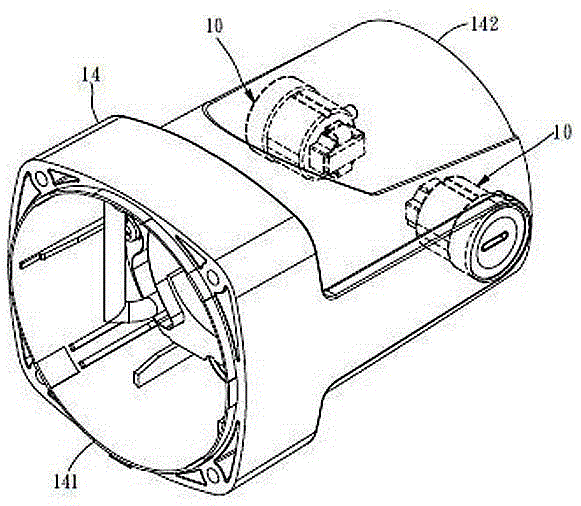

[0023] Such as figure 1 As shown, the motor carbon brush assembly 10 with stable brush pressure is arranged on the inner surface of a motor housing 14. The motor housing 14 is elongated and has an open end 141 and a closed end 142 separated by a considerable distance. There are two motor carbon brush holders 10 at opposite positions, and the installation positions of each motor carbon brush holder 10 are quite close to the closed end 142 .

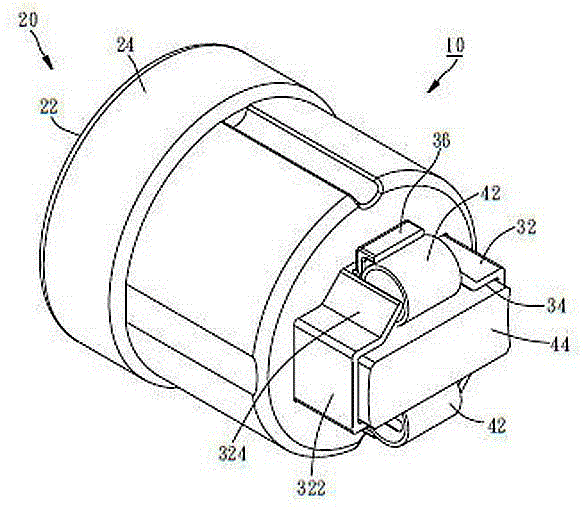

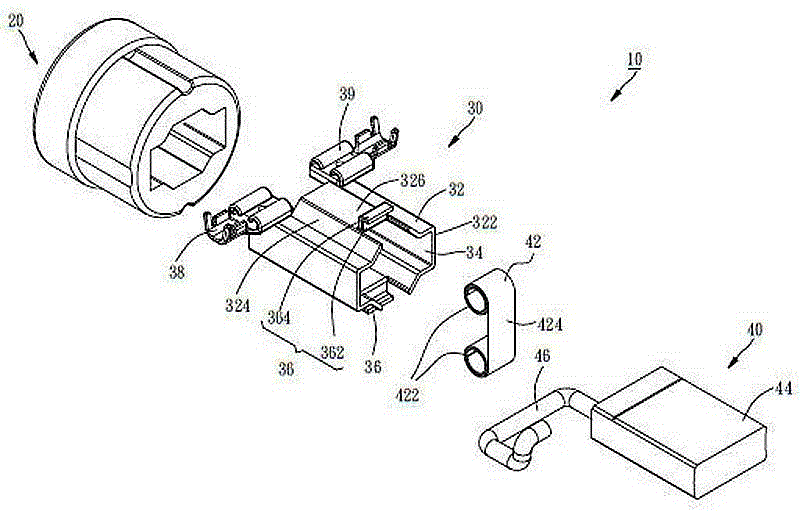

[0024] Such as figure 2 with image 3 , the motor carbon brush holder 10 is mainly composed of an insulating case 20, a conductive member 30, and a carbon brush assembly 40, wherein:

[0025] The insulating case 20 is made of insulating material (such as Bakelite), has a bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com