Preparation method of pasteurized milk

A technology of pasteurization and raw milk, applied in the direction of preservation and application of dairy products and milk, which can solve the problems of restricting the sales area of enterprises, detecting the total number of colonies exceeding the standard, and easy corruption and deterioration, so as to meet the needs of consumers and alleviate Contradictions between supply and demand, the effect of increasing confidence in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

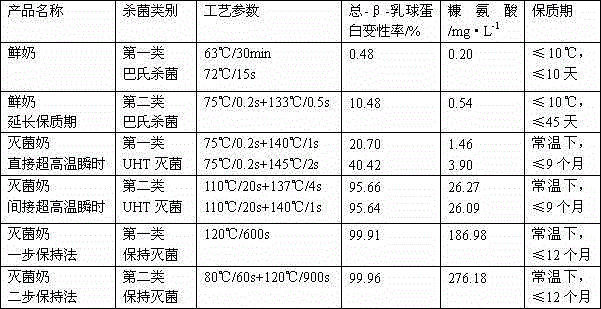

[0021] The preparation method of pasteurized milk of the present invention, its technological process is followed by raw material milk acceptance, pretreatment, primary pasteurization, homogenization, secondary pasteurization, cooling, filling and refrigeration, primary pasteurization The temperature is 72°C and the time is 15s, and the temperature of the second pasteurization is 75°C and the time is 15s.

[0022] Among them, the acceptance of raw milk is the first step in the production of pasteurized milk and an important part of controlling the quality of raw milk. Its purpose is to make the quality of raw milk meet the requirements of raw milk in the national food safety standard GB19301-2010. Generally, raw milk for pasteurized milk should reach grade two or above, the 72% alcohol test is negative, and the melamine content meets the national standard.

[0023] Pretreatment is to filter and / or centrifugally purify the accepted raw milk. Among them, filtration is mainly to...

Embodiment 1

[0035] A preparation method of pasteurized milk, its technical process is as follows:

[0036] S1. Raw milk acceptance: According to raw milk GB19301-2010 food safety national standards and enterprise standards, various indicators of raw milk are measured, and the qualified raw milk enters the next step of process;

[0037] S2. Pretreatment: Filter and centrifugally purify the raw milk that has passed the acceptance test. Filtration is to use stainless steel metal mesh and multi-layer gauze on the raw milk tank for coarse filtration, and further filter using pipeline filters. Purification is carried out by a special centrifugal milk cleaner;

[0038] S3. Standardization: adjust the fat content in the raw milk to make it standardized. If the standardized fat content is higher than that of the raw milk, it is necessary to mix the cream with the raw milk in the tank according to the calculated ratio to achieve the required fat content. If it is low For raw milk, it is necessary ...

Embodiment 2

[0044] A preparation method of pasteurized milk, its technical process is as follows:

[0045] S1. Raw milk acceptance: According to raw milk GB19301-2010 food safety national standards and enterprise standards, various indicators of raw milk are measured, and the qualified raw milk enters the next step of process;

[0046] S2. Pretreatment: Filter and centrifugally purify the raw milk that has passed the acceptance test. Filtration is to use stainless steel metal mesh and multi-layer gauze on the raw milk tank for coarse filtration, and further filter using pipeline filters. Purification is carried out by a special centrifugal milk cleaner;

[0047] S3, one-time pasteurization: perform one-time pasteurization on the pretreated raw milk, the temperature of the pasteurization is 72°C, and the time is 15s;

[0048] S4. Homogenization: use a high-pressure homogenizer to homogenize the pasteurized milk at a temperature of 60°C and a pressure of 21.0MPa;

[0049] S5, secondary pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com