A method for determining the surface roughness of glass-ceramic grinding

A glass-ceramic, surface roughness technology, applied in the field of engineering ceramics processing, can solve problems such as complex surface forming mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0145] A method for determining the grinding surface roughness of glass-ceramics includes the following steps:

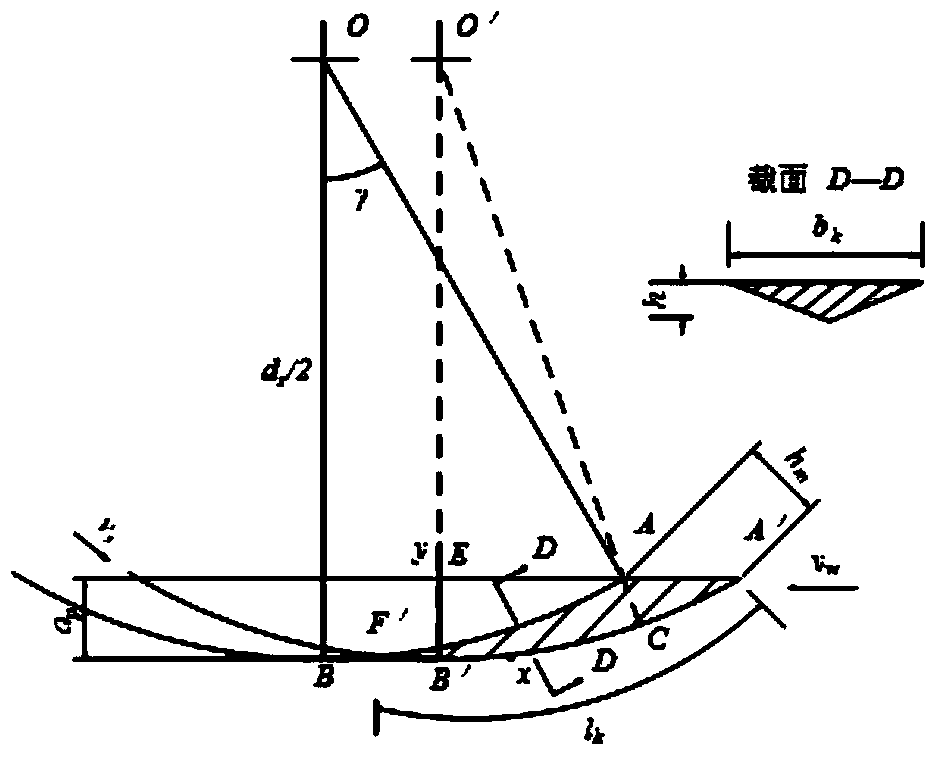

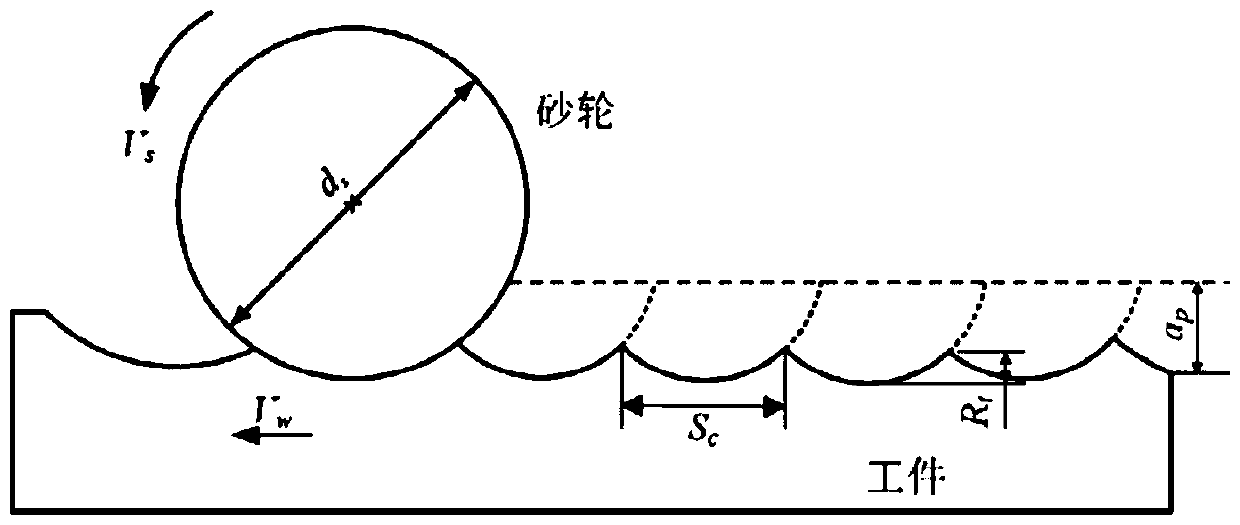

[0146] (1) According to the grinding processing conditions, the maximum undeformed chip thickness h is obtained by the following formula max :

[0147]

[0148] Where N d Is the effective number of abrasive particles per unit area, a p Is the grinding depth, d s Is the diameter of the grinding wheel;

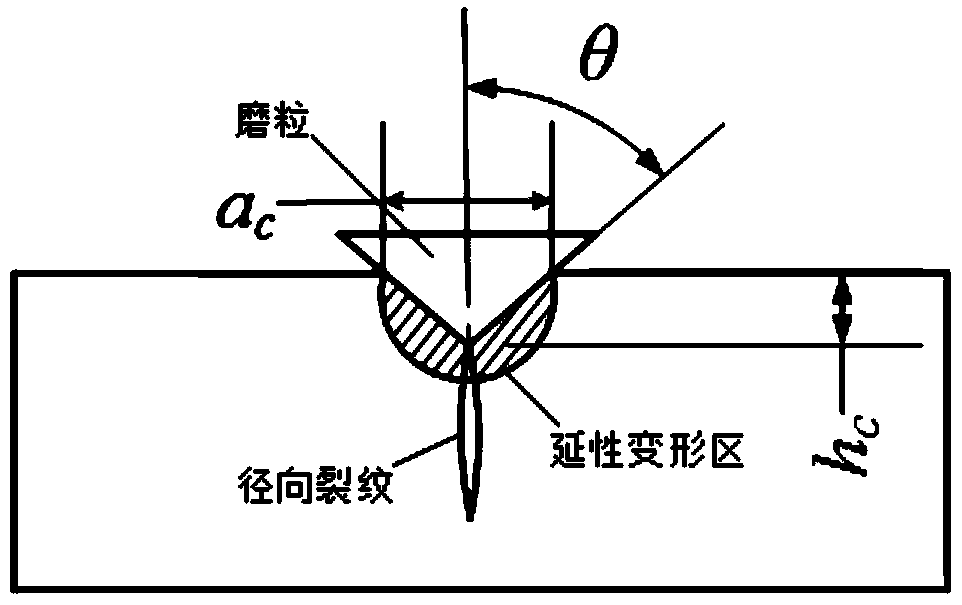

[0149] (2) According to the material properties of glass-ceramics, the ductility-ductile brittleness critical depth h is obtained by the following formulas c1 And ductile brittleness-critical brittleness depth h c2 :

[0150]

[0151] Where η 1 Is the ductility domain coefficient, η 2 Is the extension-brittle domain coefficient, K d Is the dynamic change coefficient (commonly used coefficient, usually 0.3), K IC Is the fracture toughness, θ is the half angle of the cone tip of the abrasive grain, H is the microhardness, and E is the elastic modulus;

[0152] (3) According to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap