Indexing rotating table and indexing rotating table system

A rotary table and indexing technology, which is applied in the direction of manufacturing tools, metal processing equipment, and machine tools suitable for grinding workpiece planes, etc., can solve the problem of a large number of wafer fragments, reduce energy waste, improve equipment stability and work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

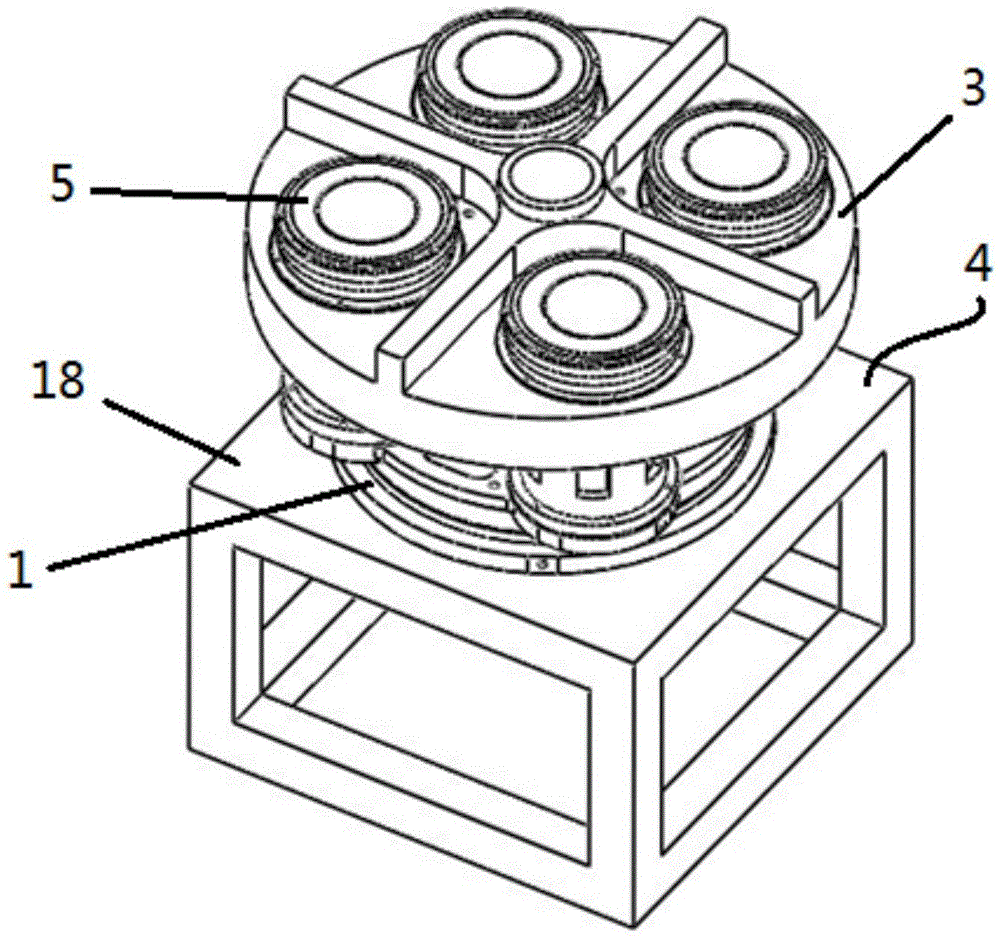

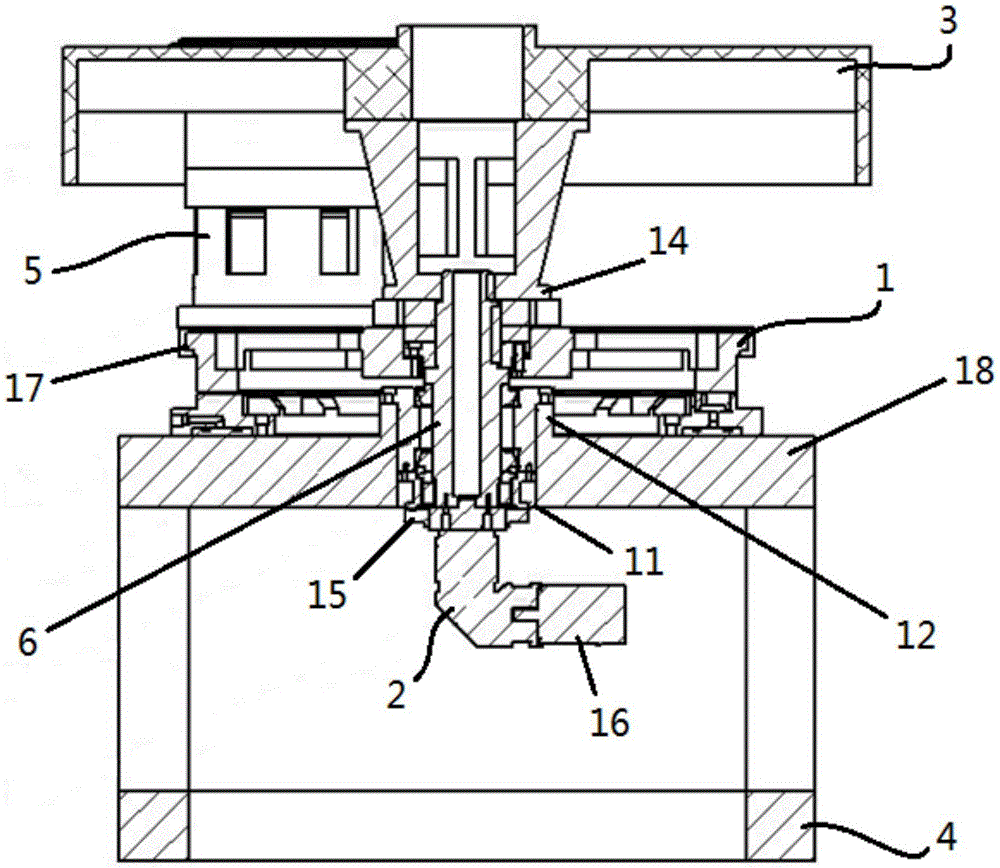

[0036] The present invention aims at the problem of a large number of fragments caused by the transfer of wafers between various devices in the process flow in the prior art, and provides an indexing rotary workbench, such as Figure 1 to Figure 6 shown, including:

[0037] Rotary air flotation structure 1, drive control structure 2, turntable frame 3, base 4 and multiple film holders 5 for placing pieces to be processed;

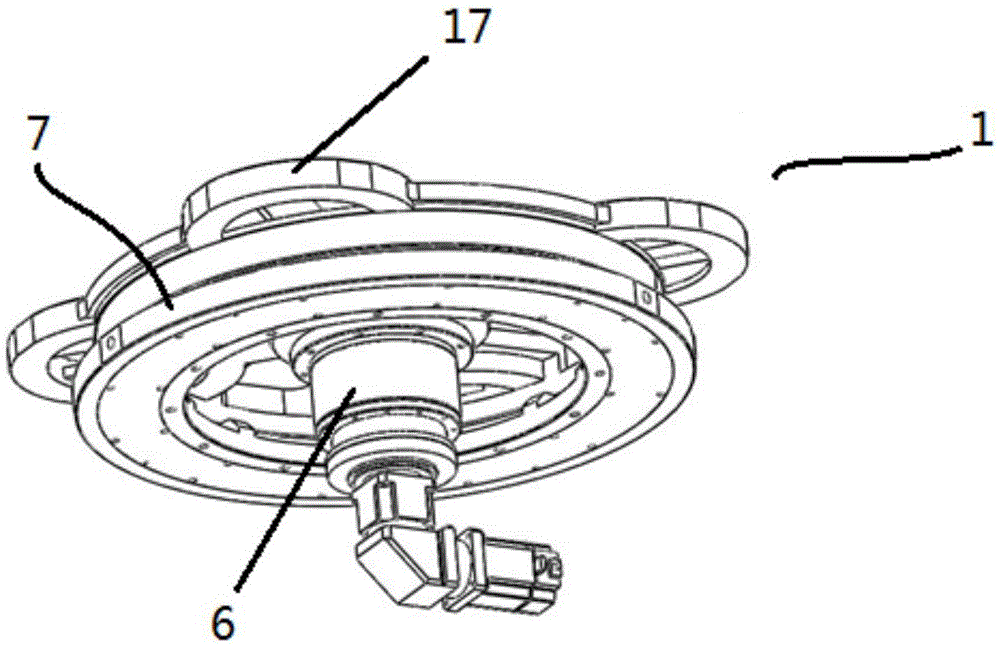

[0038] Wherein, the rotating air floating structure 1 includes a connecting shaft 6 and a bearing platform 7 fixedly connected to the middle part of the connecting shaft 6;

[0039] The turntable frame 3 includes a fixed shaft 8 and a turntable table 9 fixedly connected to the upper end portion of the fixed shaft 8, and the turntable...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap