Multifunctional workbench used for detecting zippers

A workbench and multi-functional technology, applied to multiple packages, automatic control of packaging, packaging, etc., can solve problems such as heavy workload, easy to count mistakes, and complexity, and achieve the effect of accurate inspection and measurement, and less error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

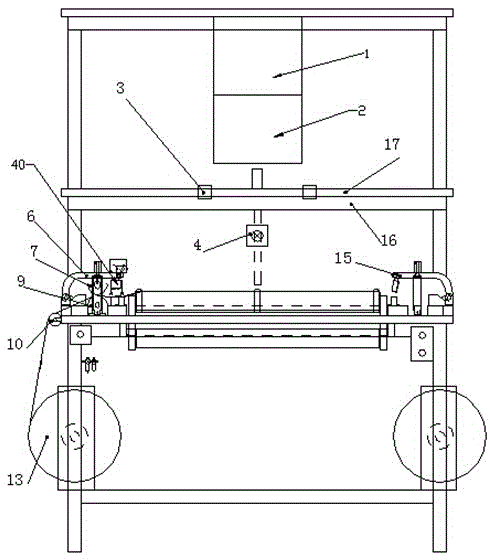

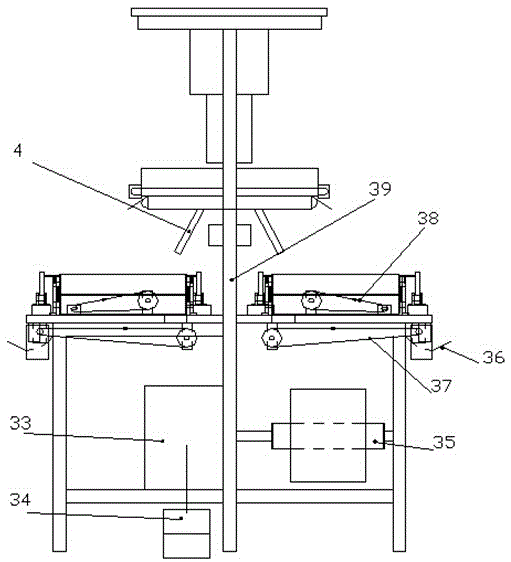

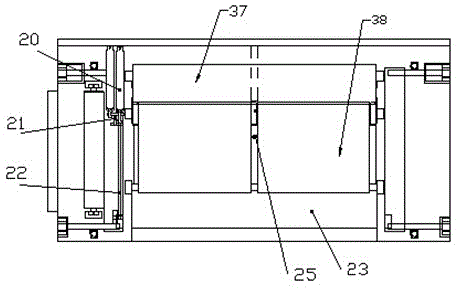

[0018] Such as figure 1 , figure 2 and image 3 As shown, the multifunctional workbench for checking zippers includes a main power switch 1, a control and display device 2, a frame 39, a packaging bag cutting device, a testing device, and a sealing device;

[0019] Described packaging bag cutting device comprises reel shaft 35 and sealing machine 40, and reel shaft 35 is installed on the frame 39, and reel shaft 35 is used for installing reel bag 13; Also includes guiding bag shaft 10, electric drum 9 and the rubber-coated drum 7; the electric drum 9 and the rubber-coated drum 7 form a group of drums; a standard cutter 21 is also included, and the standard cutter 21 is installed on the knife rest guide rail 22, and the standard cutter 21 is driven by the cutter cylinder 20; There is a cantilever 6 above the sealing machine 40, and the cantilever 6 is dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com