Flexible smoked sheet packing gunny bag sealing device

A flexible and sack technology, applied in the field of flexible packaging material sealing devices, can solve the problems of affecting the purity of tobacco leaves, increasing the difficulty of removing impurities, and using a large amount of twine, etc., so as to facilitate repeated use, improve work efficiency, save production time and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

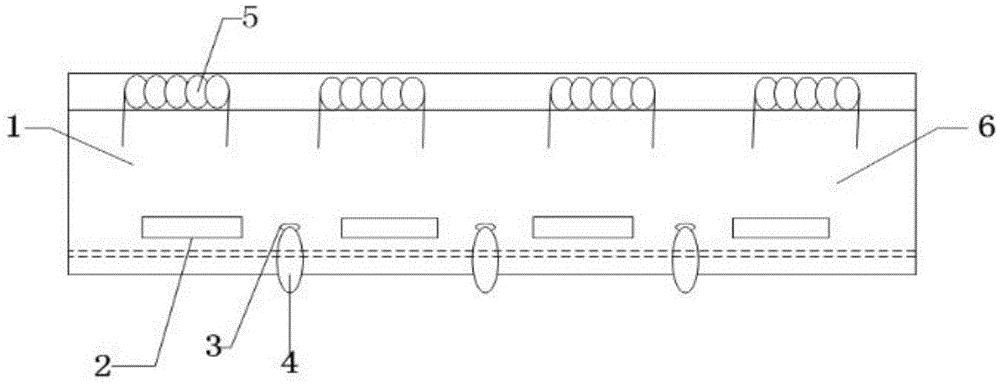

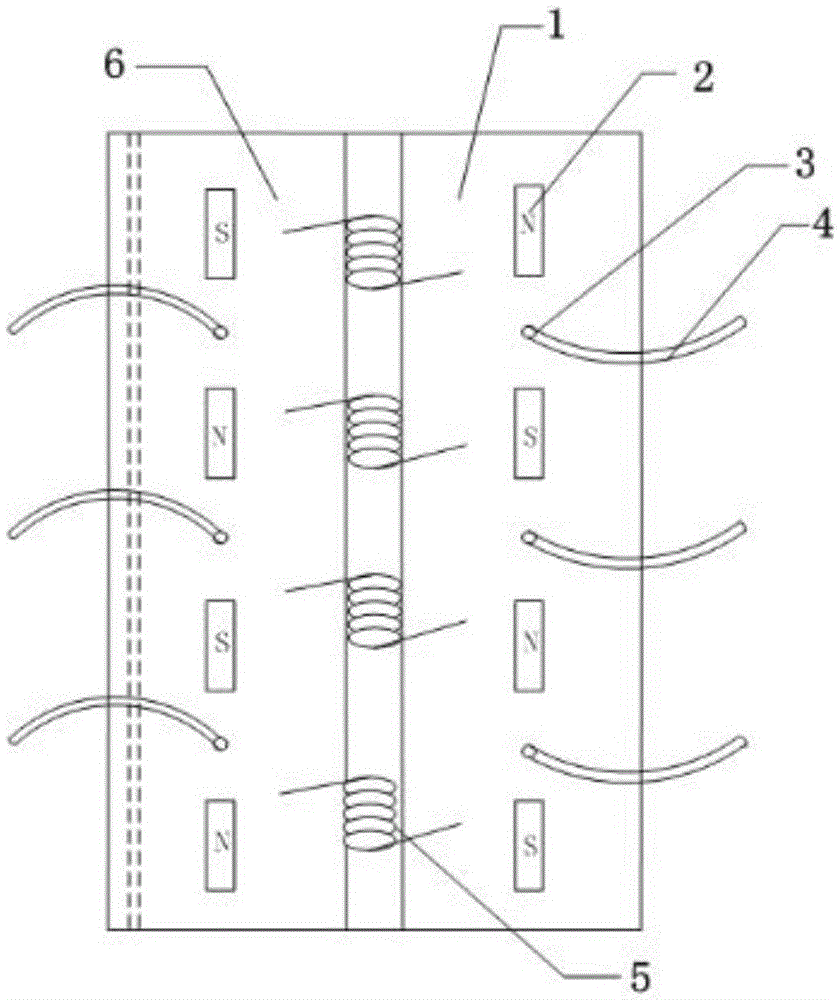

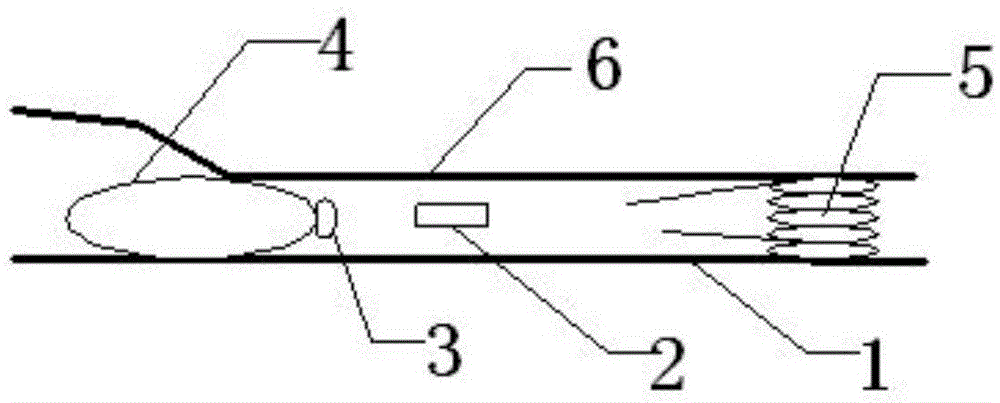

[0018] The sack sealing strip for flexible cigarette packaging of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 , 2 , 3, a flexible cigarette packaging sack sealing strip includes two flexible plastic strips 1, an arc-shaped clip 4 and a spring 5 that controls the closed state. The two flexible plastic strips 1 are connected by multiple springs 5, The outer edge of the plastic strip 1 is provided with several mounting holes 3 intermittently at corresponding positions for installing several arc-shaped clamps 4. In actual use, the arc-shaped clamps 4 are fastened into the flax sheet 7, plus the back tension of the spring 5. Make the seal firm. The magnetic strips 2 of different poles are intermittently installed at the relatively overlapping positions inside the two flexible plastic strips 1. Utilizing the combined action of the back tension of the spring 5 and the attractive force of the sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com