Variable-height conveying line

A conveyor line and height technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as unfavorable equipment fixation and docking with other equipment, inconvenient adjustment of conveyor line height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

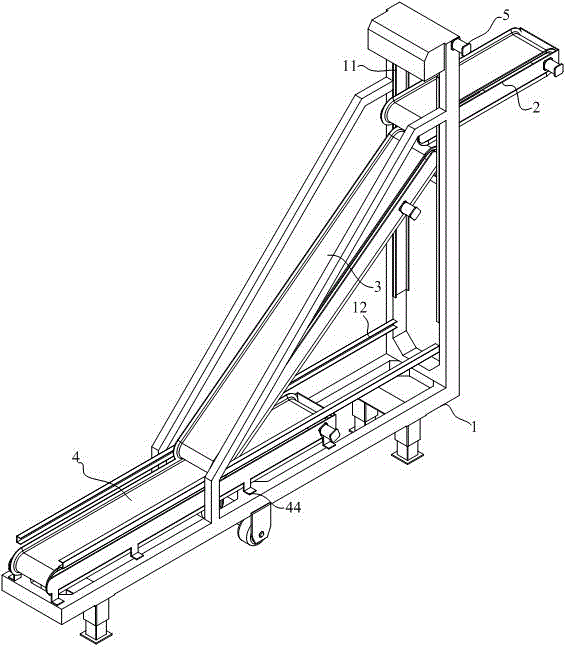

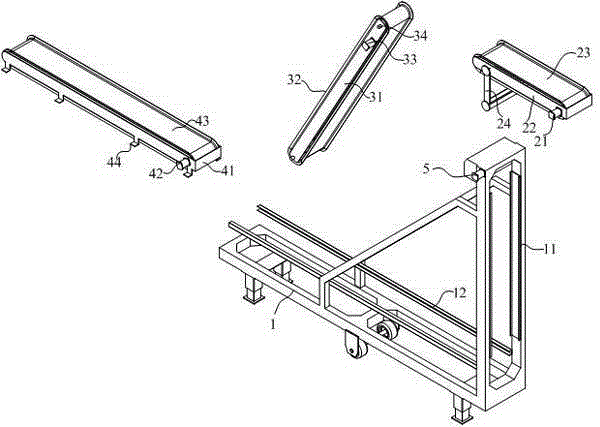

[0012] see Figure 1-Figure 2 As shown, the present invention proposes a kind of embodiment of the conveying line of variable height, support 1 and the high-end conveying line 2 that is arranged on the upper end of support 1, inclined conveying line 3, the bottom end conveying line 4 that is arranged on the bottom end of support 1 and can The lifting mechanism 5 that drives the high-end conveyor line 2 and the inclined conveyor line 3 to move up and down at the same time, the support 1 is provided with a first slide track 11 along its height direction and a second slide track 12 perpendicular to its height direction, so The high-end conveying line 2 is slidably connected with the first sliding track 11, and one end of the inclined conveying line 3 is arranged at the lower end of the high-end conveying line 2 and is correspondingly slidably connected with the first slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com