Liquid crystal medium and liquid crystal display including same

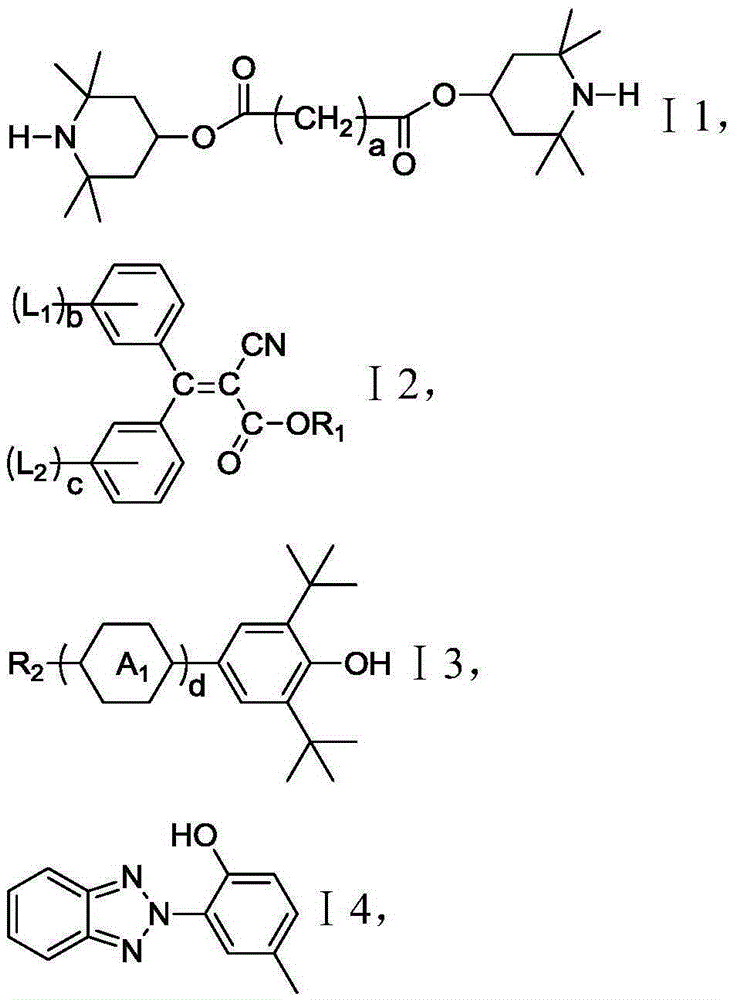

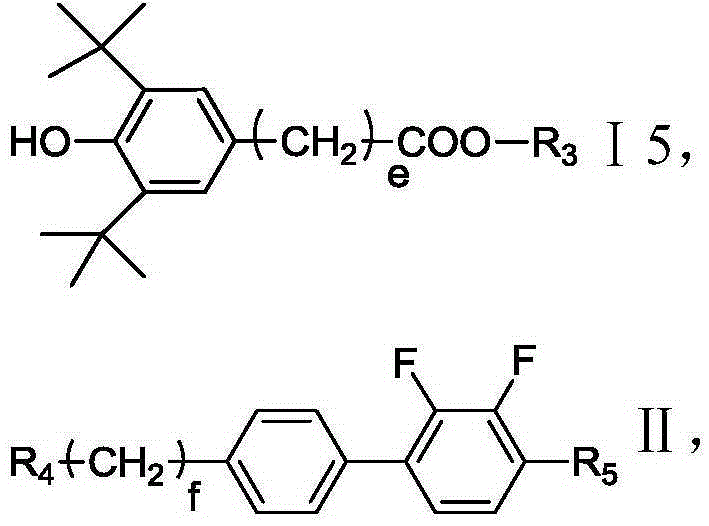

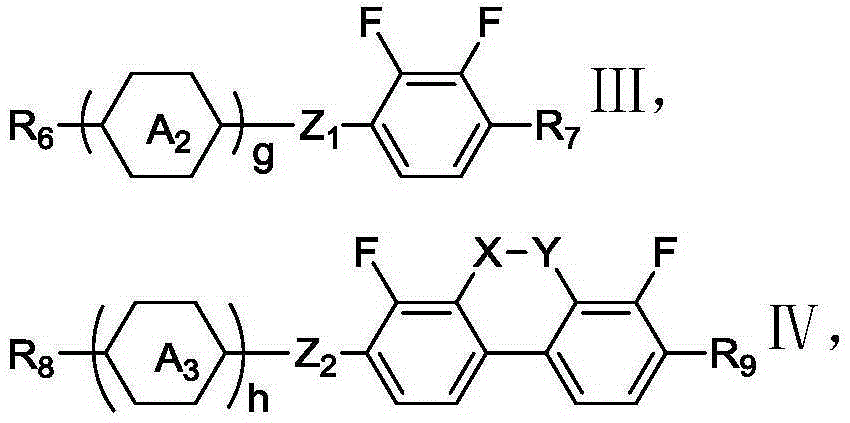

A technology of liquid crystal medium and liquid crystal compound, applied in liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of unstable UV light resistance and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0176] The preparation method of liquid crystal medium comprises the following steps:

[0177] (1) Arrange the monomers used in order;

[0178] (2) Place the stainless steel beaker on the balance, and put the monomer into the stainless steel beaker with a spoon;

[0179] (3) Add monomer liquid crystals by required weight in turn;

[0180] (4) Place the stainless steel beaker with the added material on the magnetic stirring apparatus to heat and melt;

[0181] (5) After most of the mixture in the stainless steel beaker is melted, add a magnetic rotor into the stainless steel beaker, stir the liquid crystal mixture evenly, and obtain the liquid crystal medium after cooling to room temperature.

[0182]The obtained liquid crystal medium is filled between the two substrates of the liquid crystal display for performance testing. The monomer structure, dosage (weight percentage) of the specific compound, and the performance parameter test results of the obtained liquid crystal me...

Embodiment 1

[0184] The liquid crystal medium of this embodiment was prepared according to the composition ratio of the liquid crystal medium in Table 1.

[0185] The component distribution ratio and the performance parameter thereof of the liquid crystal medium of table 1 embodiment 1

[0186]

[0187] Reliability data after adding different amounts / different types of additives in embodiment 1 of table 2

[0188]

[0189] From the above table, it can be concluded that using additives I1-4 and I2-1 alone in negative liquid crystal materials is very obvious for improving the UV resistance of liquid crystal materials, and additives I1-4 are more effective than I2-1 in terms of UV resistance The improvement is the most prominent, and when the combination of I1-4+I3-2 is used, the anti-UV and high-temperature performance of the liquid crystal material is excellent.

Embodiment 2

[0191] The liquid crystal medium of this embodiment was prepared according to the composition ratio of the liquid crystal medium in Table 3.

[0192] The component ratio of the liquid crystal composition of table 3 embodiment 2 and performance parameter thereof

[0193]

[0194] Reliability data after adding different amounts / different kinds of additives in embodiment 2 of table 4

[0195]

[0196]

[0197] From the above table, it can be concluded that using additives I1-4 and I2-1 alone in negative liquid crystal materials is very obvious for improving the UV resistance of liquid crystal materials, and additives I1-4 are more effective than I2-1 in terms of UV resistance The improvement is the most prominent, and when the combination of I1-4+I3-2 is used, the anti-UV and high temperature resistance of the liquid crystal material are excellent, and the addition of I1-4 is at 30ppm, and the addition of I3-2 is at 300ppm Excellent performance for improving reliability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com