Steel wire rope used for crane and manufacturing method of steel wire rope

A production method and technology for steel wire ropes, which are applied in textile cables, textiles and papermaking, etc., can solve the problems of poor softness, weak wear resistance, and hard steel wire ropes, and achieve the effect of stable contact state, small number of steel wires, and reduced friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

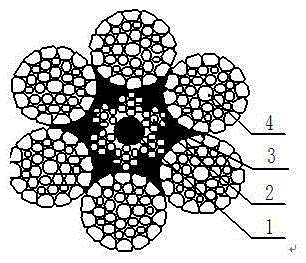

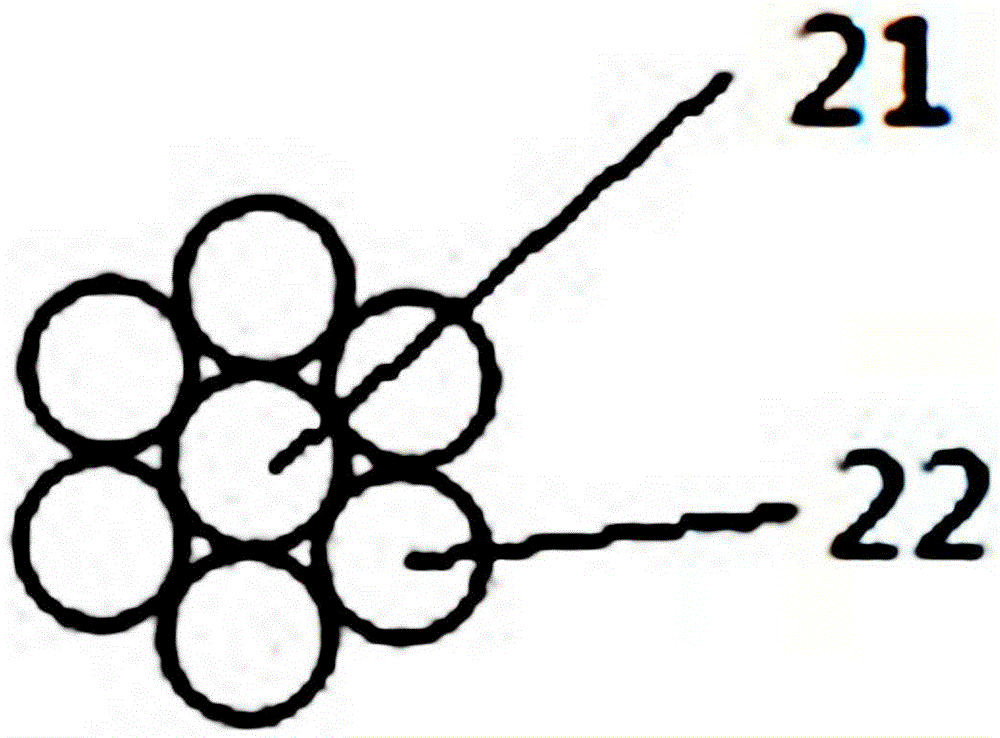

[0027] Such as figure 1 As shown, the wear-resistant and soft steel wire rope for cranes, the model is 6×K36WS+6PPF+IWRC—¢28mm, its structure includes two inner and outer layers from the cross-section, the inner layer is composed of six inner strands 2 (¢3.45mm), the outer The layer is composed of six outer strands 4 (¢9.2mm), and also includes a central strand 1 (¢5.3mm). The six inner strands 2 are evenly covered on the circumference of the central strand 1. The center strands 1 are in surface contact, and a filling strand 3 (¢2.8mm) is set between the inner layer and the outer layer. The filling strand 3, the inner strand 2, and the outer strand 4 are all surface contact.

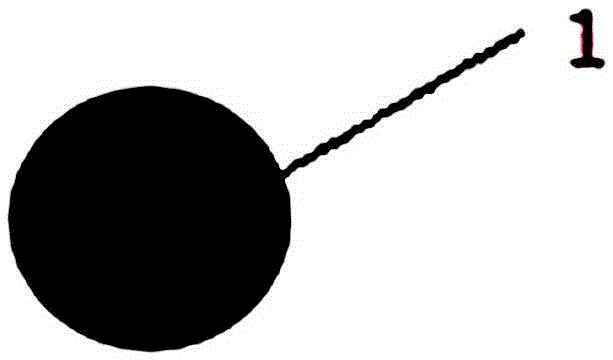

[0028] Among them, such as figure 2 As shown, the central strand 1 is a high-strength polyester fiber rope composed of more than 1000 spirally rotating polyester fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com