Dust sucking and removing system

A technology for dust collection and dust removal, which is applied in road cleaning, construction, cleaning methods, etc., and can solve problems such as affecting dust removal operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

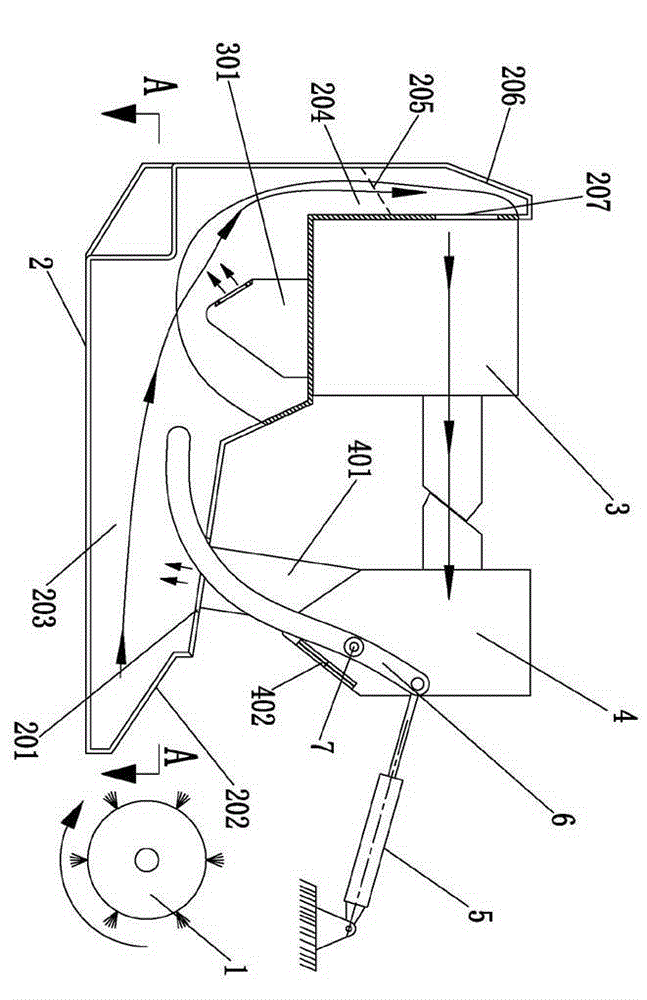

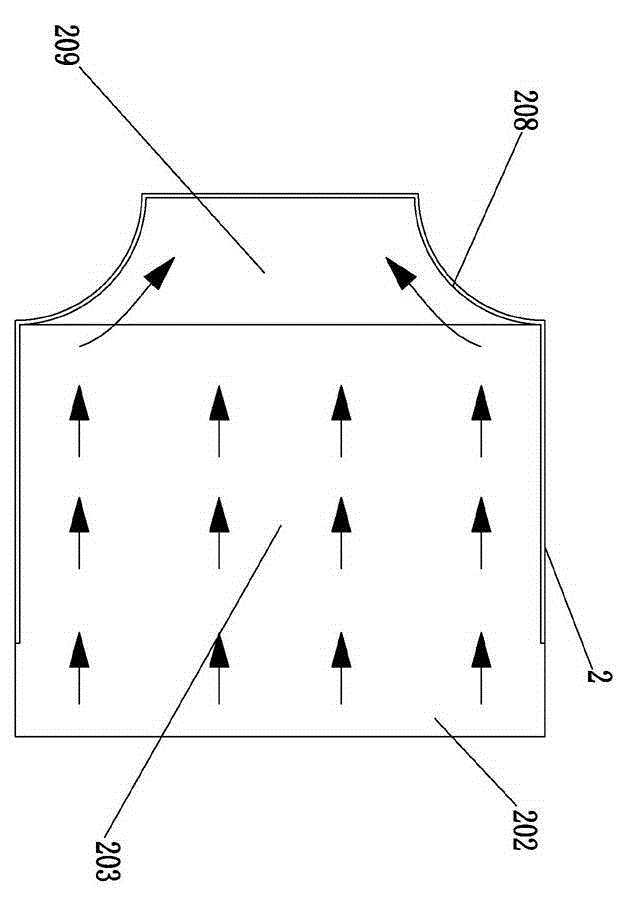

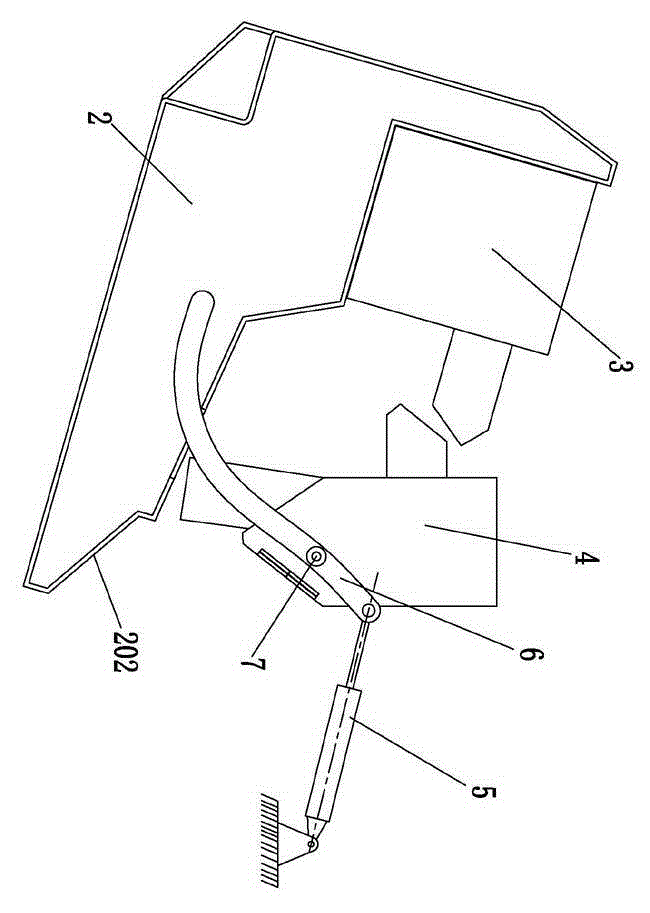

[0020] Such as Figure 1-4 As shown, a dust collection and dust removal system includes a sweeping brush 1, a dust collection bucket 2 with a box structure, a coarse filter mechanism 3, and a fine filter mechanism 4. The air outlet side of the coarse filter mechanism 3 is connected to the air inlet side of the fine filter mechanism 4. Pass; the dust collecting bucket 2 is provided with a dust inlet 202, and the sweeping brush 1 is arranged on the vehicle frame and faces the dust inlet 202 when cleaning. The tuyere 207; the fine filter mechanism 4 is provided with a blower fan 402 that can cause the internal negative pressure of the fine filter mechanism 4, and the dust collecting chamber 203 and the collecting chamber 204 that are connected to each other are arranged in the dust collecting bucket 2 in sequence according to the air flow direction. The dust chamber part 203 is in a horizontal state during cleaning, the dust collection chamber part 203 is connected to the dust in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com