Wet junction forming method

A forming method and a technology of wet jointing, which are applied in the fields of construction, building structure, and building materials processing, etc., can solve problems such as hidden quality problems, labor-intensive manual chiseling, and high labor intensity, and achieve convenient, simple, and delayed construction. The effect of setting time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with examples, so that those skilled in the art can implement it with reference to the description.

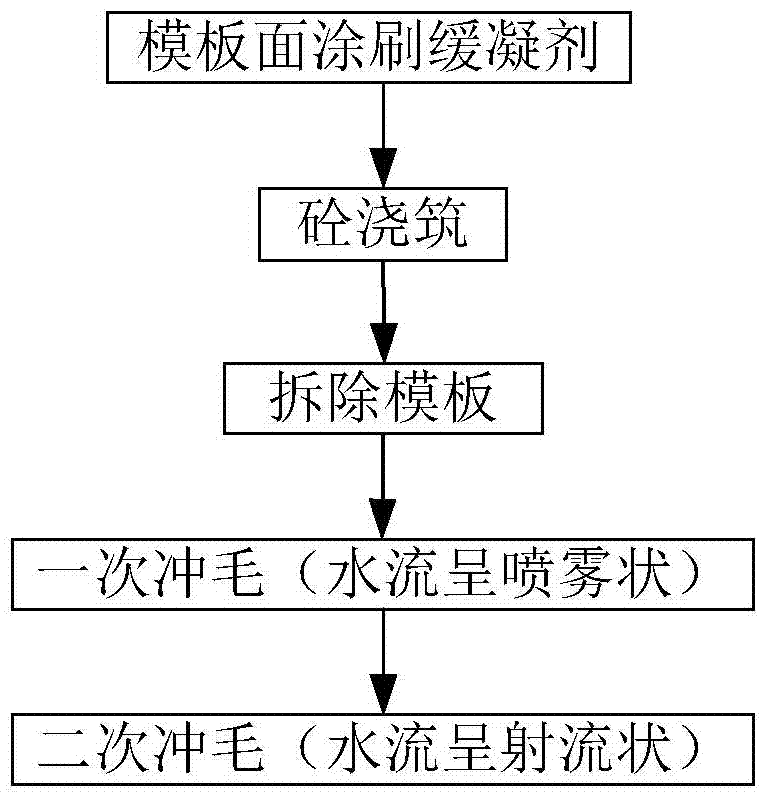

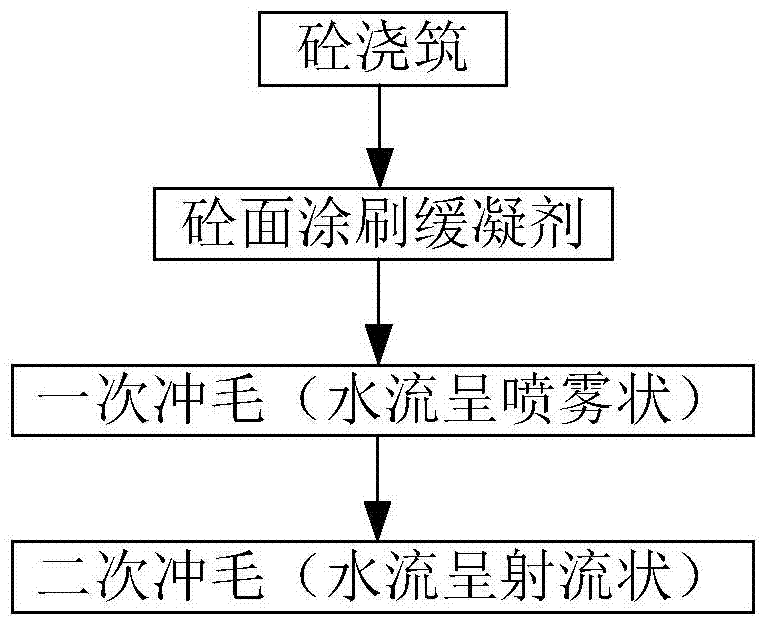

[0027] Such as figure 1 , 2 As shown, the present invention provides a wet joint forming method, comprising:

[0028] For the horizontal joint surface, apply the first retarder evenly after closing the surface, leave it for 3 to 5 hours, first wash it with the first high-pressure water, and then wash it with the second high-pressure water to obtain a horizontal wet joint surface;

[0029] For the vertical joint surface, evenly brush the second retarder on the surface of the formwork used to cover the vertical joint surface before pouring, and leave it for 12 to 24 hours after pouring, first wash it with the first high-pressure water, and then use the second High-pressure water washing, get vertical wet joint surface;

[0030] Wherein, the water pressure of the first high-pressure water is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap