Wear-resistant repair material for CFB boiler and preparation method of wear-resistant repair material

A circulating fluidized bed and repairing material technology, which is applied in the field of wear-resistant materials preparation, can solve problems such as poor effects, achieve the effects of filling harmful pores, slowing down hydration reactions, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

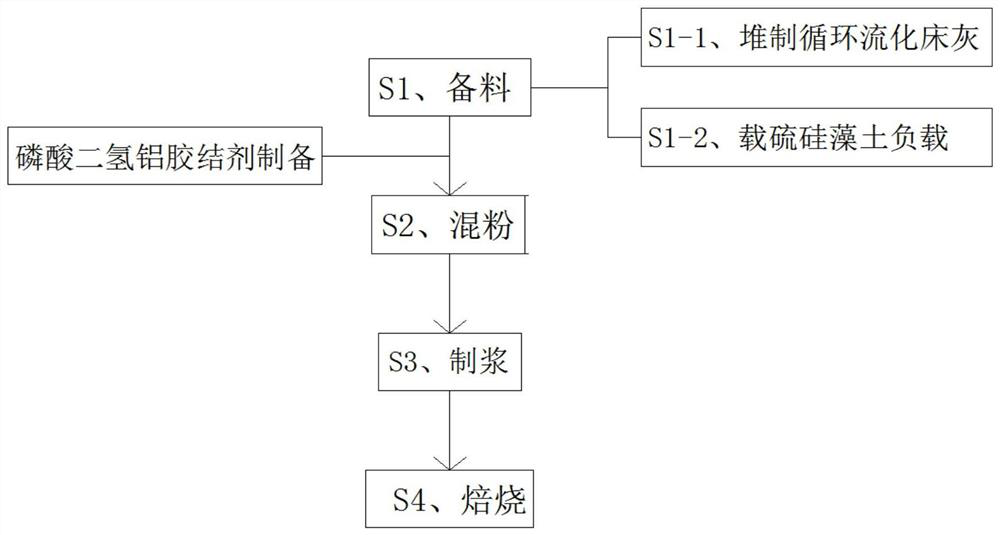

Method used

Image

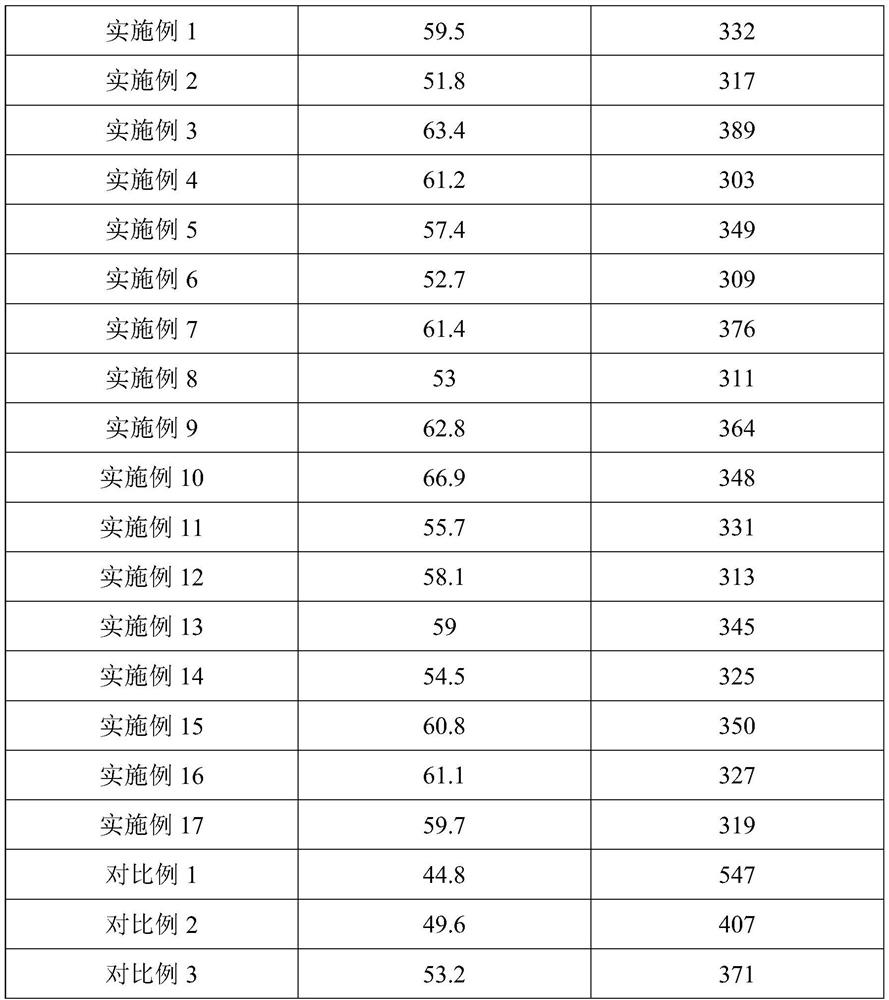

Examples

Embodiment 1

[0030] A wear-resistant repair material for a CFB circulating fluidized bed boiler, comprising 47 parts by weight of brown corundum powder, 4 parts of modified circulating fluidized bed ash, 1.7 parts of aluminum dihydrogen phosphate cement, 0.9 parts of explosion-proof fiber, ceramic 0.8 parts of fiber, 0.4 parts of dispersant, 2.5 parts of zirconia powder, 3 parts of yttrium oxide powder, 1 part of titanium diboride powder;

[0031] The average particle size of brown corundum powder is 1.5 mm, the average particle size of zirconia powder is 0.8 mm, the average particle size of yttrium oxide powder is 260 μm, and the average particle size of titanium diboride powder is 500 μm;

[0032] The average particle size of the modified circulating fluidized bed ash is 65 μm, and the modified circulating fluidized bed ash is the circulating fluidized bed ash loaded with sulfur-loaded diatomite, including 2.5 parts of circulating fluidized bed ash, 1 part of diatomite and 0.5 parts of s...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, the difference lies in that the proportion of the components of the wear-resistant repairing material is different.

[0047] A wear-resistant repair material for a CFB circulating fluidized bed boiler, comprising 45 parts by weight of brown corundum powder, 3 parts of modified circulating fluidized bed ash, 1.5 parts of aluminum dihydrogen phosphate cement, 0.8 parts of explosion-proof fiber, ceramic 0.6 parts of fiber, 0.2 parts of dispersant, 2 parts of zirconium dioxide powder, 2.5 parts of yttrium oxide powder, and 0.8 part of titanium diboride powder.

Embodiment 3

[0049] This embodiment is basically the same as Embodiment 1, the difference lies in that the proportion of the components of the wear-resistant repairing material is different.

[0050] A wear-resistant repair material for a CFB circulating fluidized bed boiler, comprising 50 parts by weight of brown corundum powder, 5 parts of modified circulating fluidized bed ash, 2 parts of aluminum dihydrogen phosphate cement, 1 part of explosion-proof fiber, ceramic 0.9 parts of fiber, 0.5 parts of dispersant, 2-3 parts of zirconium dioxide powder, 2.5-4 parts of yttrium oxide powder, and 0.8-1.5 parts of titanium diboride powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com