Preparation method of polycarboxylic acid water reducer containing paw type short side chains

A technology of polycarboxylic acid series and water reducing agent is applied in the field of polycarboxylic acid series water reducing agent for building material cement concrete, which can solve the problems of high cost, complex synthesis process, general mud resistance and the like, and achieves high yield of finished products. , the response is simple and easy, and the transportation is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

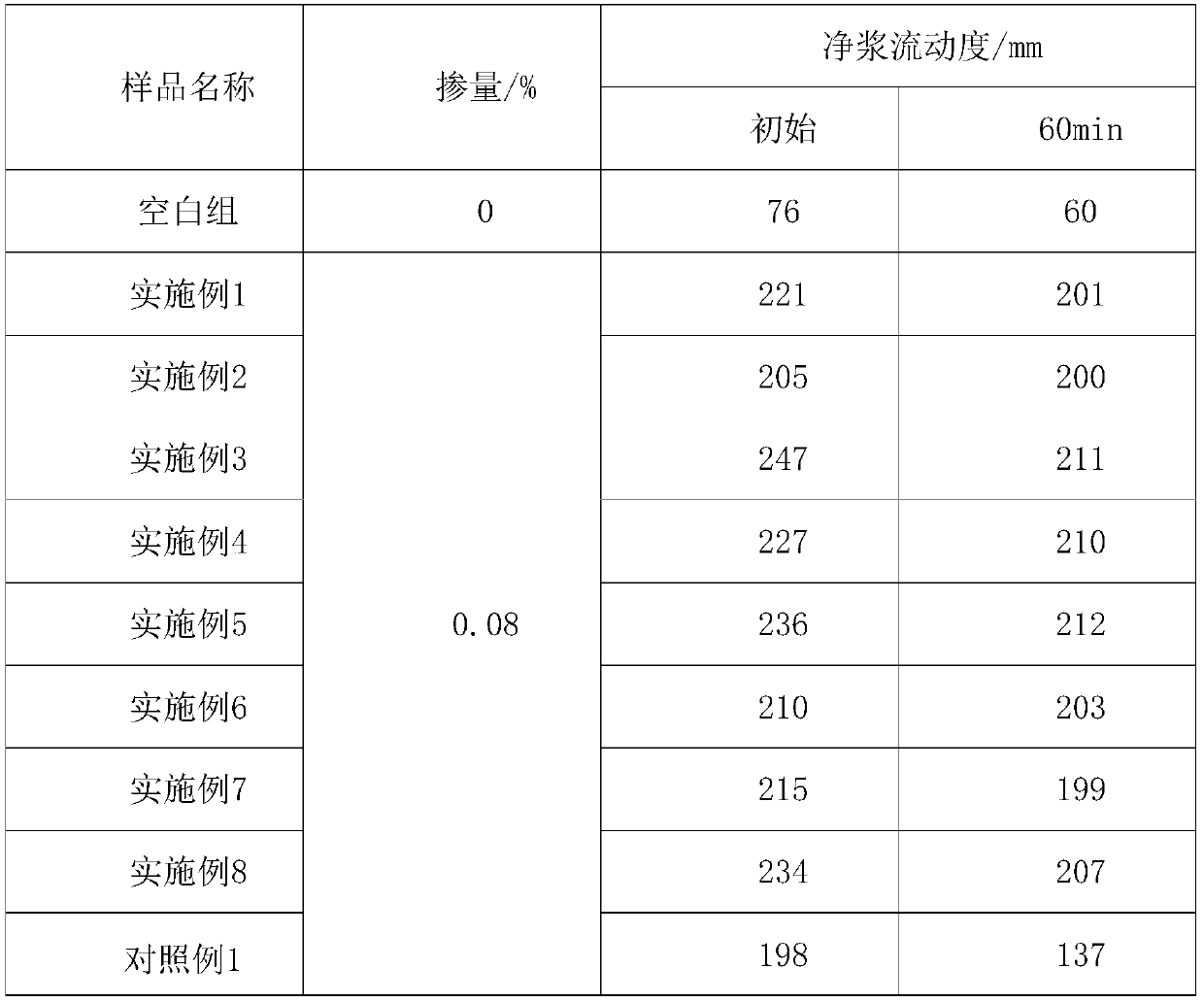

Examples

Embodiment 1

[0035] A method for preparing a polycarboxylate water-reducer containing claw-type short side chains, the specific steps are as follows:

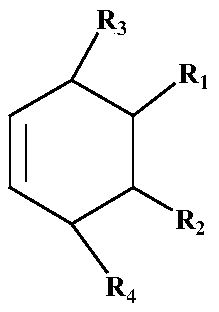

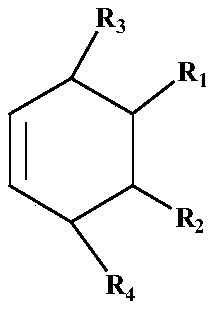

[0036] S1. Preparation of claw-type unsaturated small monomers: 1.0 mol cis-hexadienedioic acid and 1.0 mol glutaconedic acid were subjected to Diels-Alder reaction in ethanol solution at 50°C, stirred for 120 minutes, and water was added to obtain the mass fraction 50% claw-type unsaturated small monomers;

[0037] S2, the preparation method of claw type short side chain polycarboxylate water reducer: 1.0mol claw type unsaturated small monomer obtained in step S1, 2.0mol acrylic acid, 1.0mol methallyl vinyl ether (2400g / mol), 0.1mol ammonium persulfate, 0.20mol 2-mercaptopropionic acid and 0.02mol L-ascorbic acid, carry out free radical polymerization at 30°C for 4 hours, add sodium hydroxide to adjust the pH value to 7, and add water to obtain the mass concentration It is a 40% claw-type short side chain polycarboxylate water reducer. ...

Embodiment 2

[0039] A method for preparing a polycarboxylate water-reducer containing claw-type short side chains, the specific steps are as follows:

[0040]Preparation of S1 claw-type unsaturated small monomer: 1.0mol cis-hexadienedioic acid and 1.2mol maleic acid were subjected to Diels-Alder reaction in ethanol solution at 50°C, stirred for 80min, and water was added to obtain the mass fraction 45% claw-type unsaturated small monomers;

[0041] The preparation method of S2 claw type short side chain polycarboxylate water reducer: 1.0mol claw type unsaturated small monomer obtained in step S1, 1.0mol methylene succinic acid, 1.0mol allyl vinyl ether ( 1800g / mol), 0.15mol hydrogen peroxide, 0.1mol mercaptoethanol and 0.3mol formaldehyde sodium sulfoxylate, carry out free radical polymerization reaction at 50°C for 5h, add sodium gluconate to adjust the pH value to 5, add water to obtain a mass concentration of 20% of a claw-type short side chain polycarboxylate superplasticizer.

Embodiment 3

[0043] A method for preparing a polycarboxylate water-reducer containing claw-type short side chains, the specific steps are as follows:

[0044] Preparation of S1 claw-type unsaturated small monomer: 1.0 mol cis-hexadienedioic acid and 1.1 mol fumaric acid were subjected to Diels-Alder reaction in ethanol solution at 40°C, stirred for 100 minutes, and water was added to obtain the mass fraction 45% claw-type unsaturated small monomers;

[0045] The preparation method of S2 claw-type short side chain polycarboxylate water-reducer: 1.0mol claw-type unsaturated small monomer obtained in step S1, 3.0mol methacrylic acid, 1.0mol isopentyl vinyl ether (3000g / mol), 0.15mol potassium persulfate, 0.2mol mercaptoacetic acid, and 0.03mol thioglycollate, carry out free radical polymerization for 5 hours at a temperature of 50°C, add sodium hydroxide to adjust the pH value to 6, and add water to obtain a mass concentration of 30%. A claw-type short side chain polycarboxylate water reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com