A modified calcium oxide expanded clinker, its preparation method and application

A technology of expanding clinker and calcium oxide, which is applied in the field of building materials and concrete admixtures, can solve the problems of calcium oxide expanding clinker such as weathering resistance, poor moisture resistance, fast hydration speed, and weak shrinkage compensation ability, etc. Significant benefits, long shelf life, and easy access to results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of modified calcium oxide expanded clinker by sulfated coating (using commercially available calcium oxide expanded clinker as raw material)

[0044] Grinding and crushing commercially available calcium oxide expanded clinker into a specific surface area of 300m 2 / kg of powder. Weigh 100g of expanded clinker powder, spread it flat in the reaction vessel and place it in the holding furnace; it contains 80% SO 2 , 20%O 2 After a period of ventilating reaction, take out the reaction container with calcium oxide expansion clinker; after cooling, weigh the modified quality of calcium oxide expansion clinker to determine the amount of calcium sulfate package. The volume of the mixed gas per 1 L of the holding furnace was 0.04 L / min, and the reaction temperature was 100°C.

[0045] Table 1 shows the chemical composition (wt.%) of the commercially available calcium oxide-based expanded clinker.

[0046]

[0047]

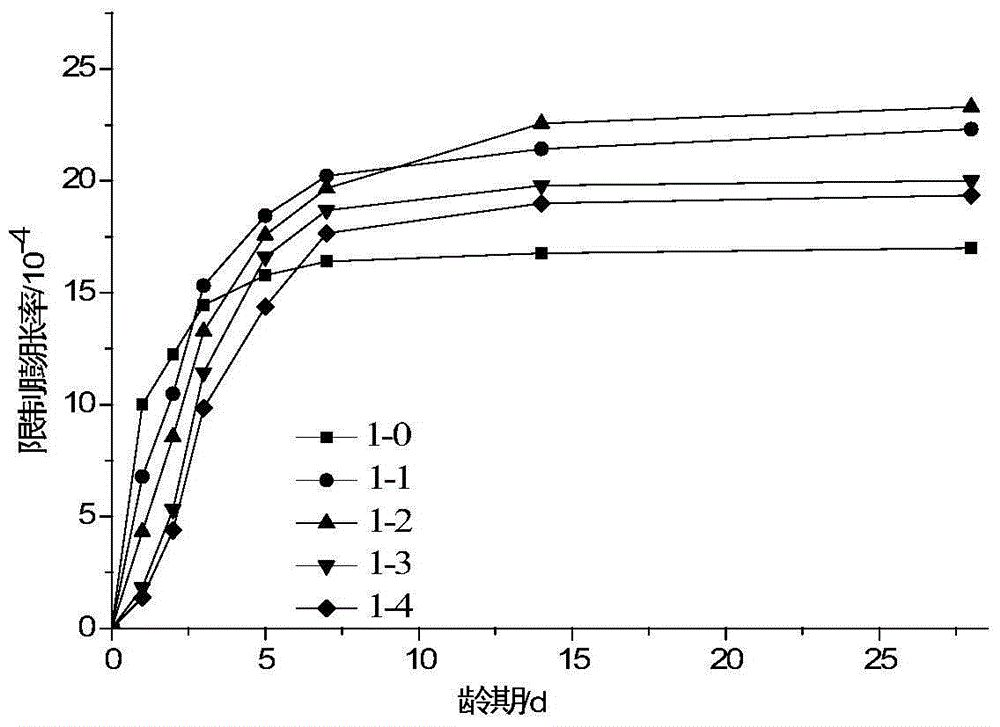

[0048] Table 2 shows the effect of ...

Embodiment 2

[0061] (1) Preparation of modified calcium oxide-based expanded clinker by sulfated coating (use industrially produced sulfur-containing tail gas, and commercially available calcium oxide-based expanded clinker as raw material).

[0062] my country is a big coal-burning country, and coal accounts for 75% of the total primary energy consumption. The massive consumption of energy has caused serious air pollution, the most prominent of which is SO 2 Acid rain hazards caused by gas emissions. At present, my country's total sulfur dioxide emission ranks first in the world, and the economic loss caused by sulfur dioxide pollution is more than 100 billion yuan. Expansion of clinker with calcium oxide and SO in exhaust gas 2 On the one hand, it achieves the purpose of calcium-based desulfurization and fixation, and reduces pollution; on the other hand, it improves the expansion performance of calcium oxide-based expansion clinker.

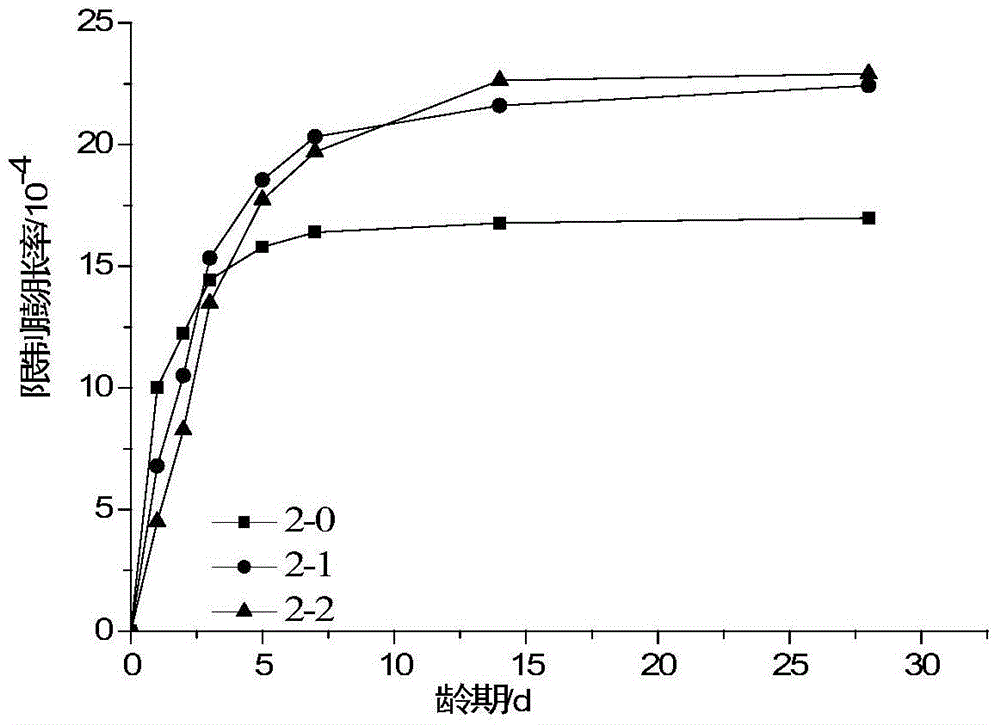

[0063] Using industrially produced sulfur-contain...

Embodiment 3

[0076] (1) Preparation of sulfation-coated modified calcium oxide expanded clinker (using commercially available calcium oxide expanded clinker as raw material)

[0077] Weigh 120.0g of CaO clinker and put it into a 500ml three-necked round-bottomed flask filled with absolute ethanol. A polytetrafluoroethylene stirrer was installed in the middle of the three-neck round bottom flask. will absorb the full concentration of 98% H 2 SO 4 Insert the dropper into one side port of the three-neck flask. The stirrer stirs the CaO clinker at 150r / min; at the same time, the concentrated H in the dropper 2 SO 4 Slowly titrate into the CaO clinker. Through physical adsorption and chemical reaction, a large amount of dense calcium sulfate is formed on the surface of CaO expanded clinker powder. Then filter and dry the modified calcium oxide expanded clinker at 80-105 DEG C to separate the sulfated coated modified calcium oxide expanded clinker from the organic solvent.

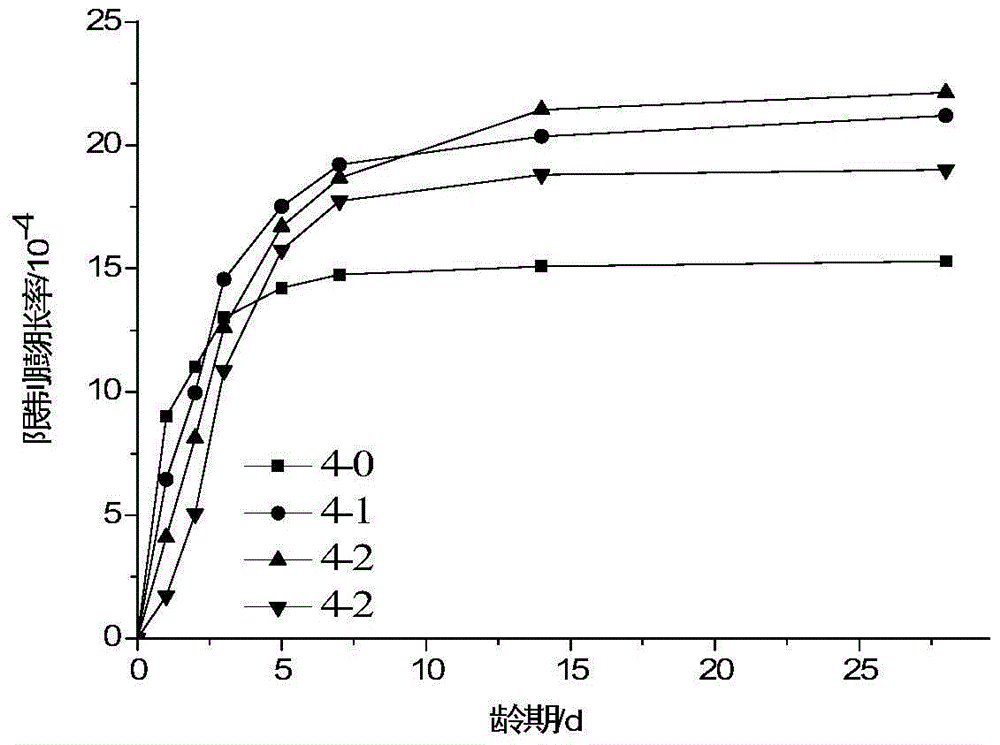

[0078] Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com