Extending-out gear shifting mechanism of mini-tiller

A technology of speed regulating mechanism and tiller, which is applied in the direction of vehicle gearboxes, agricultural machinery and implements, mechanical equipment, etc. It can solve the problems that the selection range is not wide enough and cannot meet the actual production situation, and achieves strong practicability and wide selection range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

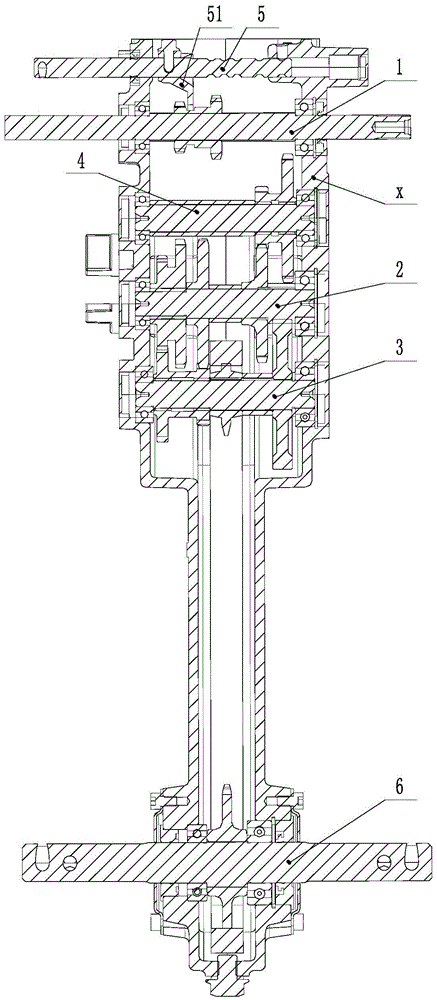

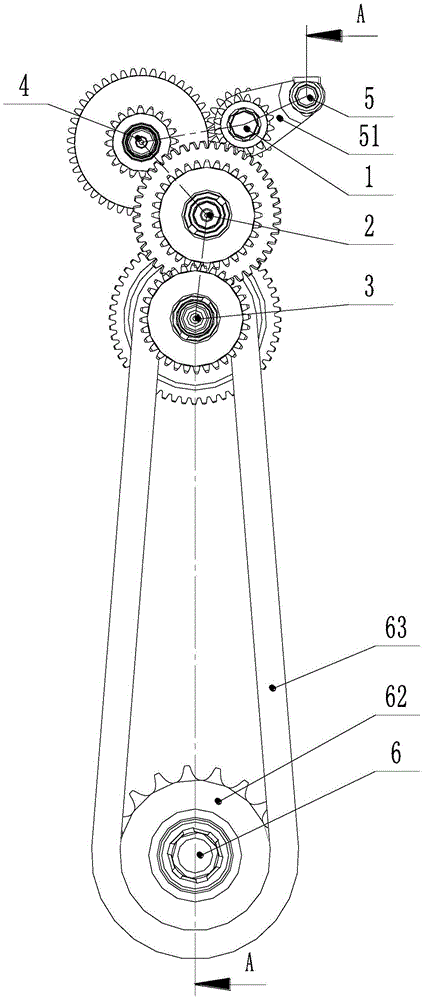

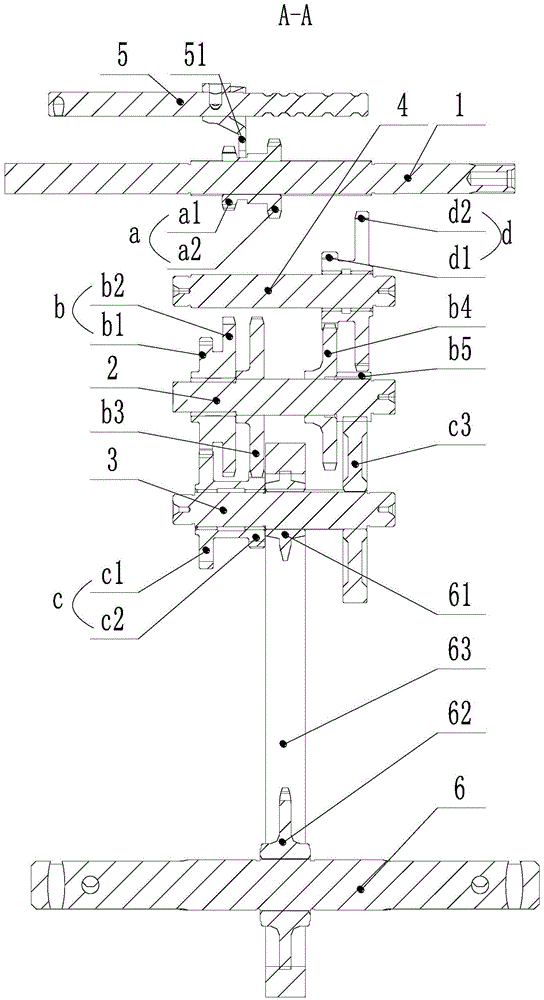

[0023] like figure 1 , figure 2 and image 3 As shown, a gear-shifting and speed-regulating mechanism of a penetrating micro-tiller includes a box (x), and a main shaft (1), a secondary shaft (2), and an output shaft (3) parallel to each other are arranged in the box (x). ) and the reverse gear shaft (4), wherein the ends of the auxiliary shaft (2), the output shaft (3) and the reverse gear shaft (4) are installed on the inner wall of the box (x) through bearings respectively, and the main shaft (1) Installed on the box (x) through bearings, the two ends of the main shaft (1) pass through the box (x) respectively, and one of the exit ends of the main shaft (1) is provided with The outer spline is provided with a circumferential limit groove at the other end of the main shaft (1), and a flat key is provided on the main shaft (1) outside the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com