Compact shelf driving device

A transmission device and compact rack technology, applied in the field of compact racks, can solve problems such as unreasonable transmission coordination, poor transmission stability of the transmission shaft, and large hand shaking force, etc., to achieve a reasonable coordination transmission mode, stable operation, and strong load capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

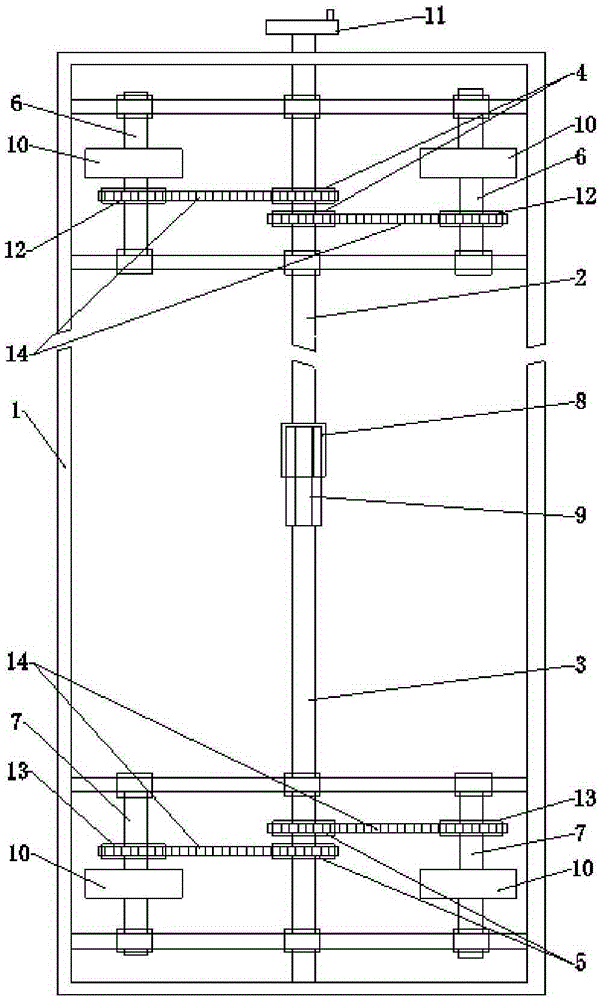

[0009] In order to further understand the technical solutions of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings.

[0010] like figure 1 As shown, the compact rack transmission device of the present embodiment comprises a driving shaft 2 and a corresponding driven shaft 3 positioned on the chassis 1 of the compact rack, and two driving gears 4 and 4 are connected to the driving shaft 2 and the driven shaft 3 respectively. Two driven gears 5, and the corresponding road wheels etc. which are movably connected to the underframe 1 respectively.

[0011] The driving shaft 2 and the driven shaft 3 are respectively arranged on opposite ends of the chassis 1 through corresponding bearing devices; the outer end of the driving shaft 2 near the chassis is connected with a driving wheel 11, and the opposite ends of the driving shaft 2 and the driven shaft 3 The ends are respectively connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com