Electric fan heater

A fan and electric heating technology, used in electric heating systems, space heating and ventilation, household heating, etc., can solve the problems of low thermal efficiency of heating components, reduced indoor oxygen, and large power consumption, and achieve strong heating effect. , the power consumption is small, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is further described:

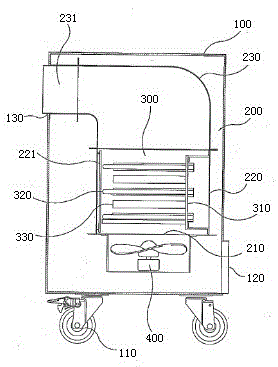

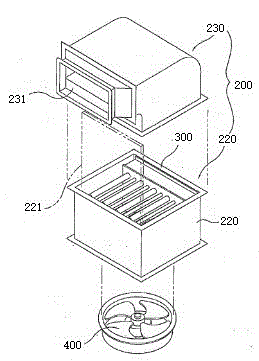

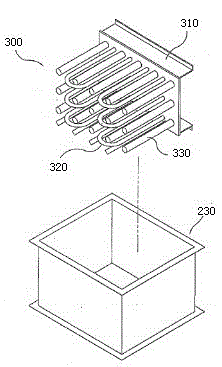

[0021] As shown in the drawings, an electric heater is provided with a box body 100, an air inlet 120 is provided at the lower end of the rear side of the box body 100, an air outlet 130 is provided at the upper end of the front side of the box body 100, and an air outlet 130 is provided at the bottom of the box body 100. The casters 110 that can move, the structure of the above-mentioned components and the interconnection between them are the same as the prior art, so I won’t repeat them here. The pipe box 200 composed of pipes 230, the lower end of the heating body 220 in the pipe box 200 is provided with an air supply device 400, the air supply device 400 is connected with an external power supply through a wire, and the air supply device 400 passes the external air through the box body 100 The air inlet 120 at the lower end and the air inlet 210 on the heating body 220 in t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap