Carbon fiber heating rail connector protection device

A protection device, carbon fiber technology, applied in the application field of indoor heating technology, can solve the problems existing in the lower layer, the upper heat and the lower cooling, the uneven temperature distribution, etc., and achieve the effects of moisture-proof, leakage-proof and good waterproof.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

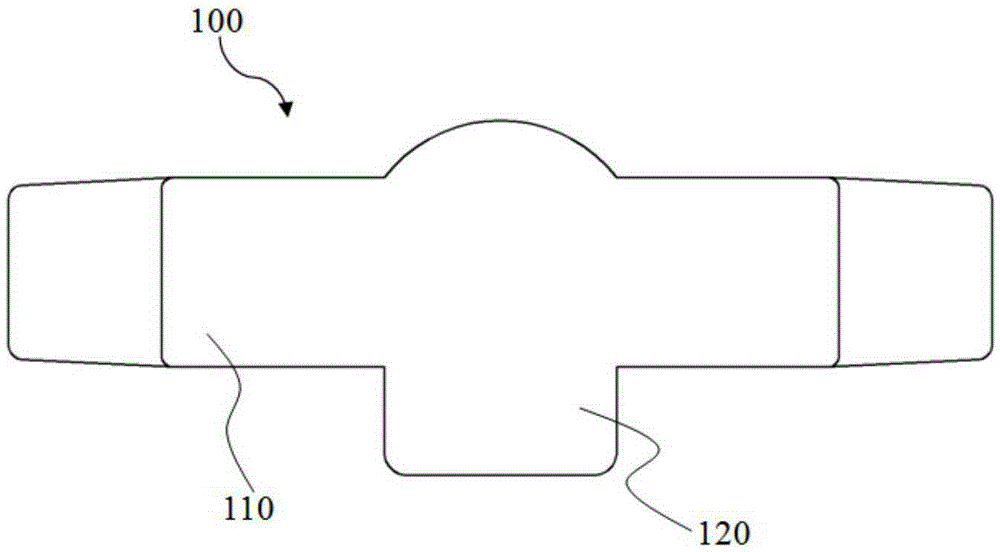

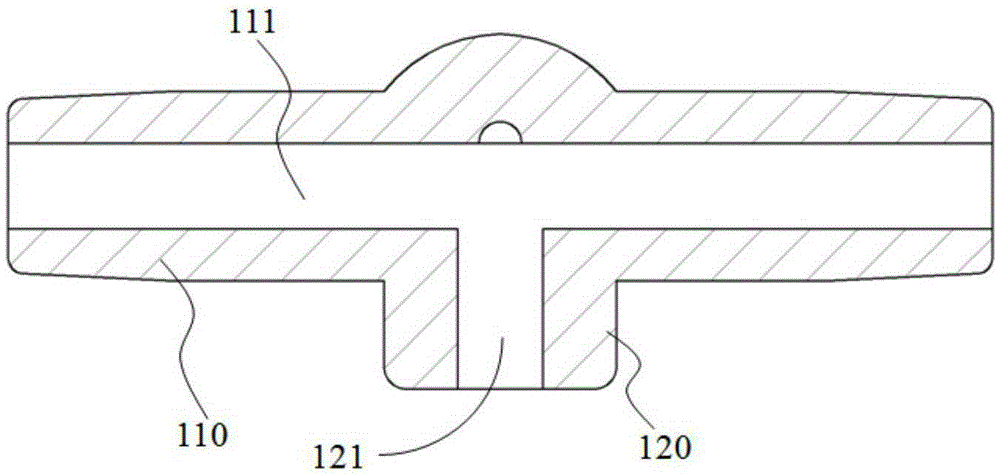

[0030] Such as figure 1 , figure 2 As shown, it shows a preferred embodiment of the carbon fiber hot rail joint protection device of the present invention.

[0031] In this embodiment, the carbon fiber hot rail joint protection device 100 includes a power cord connecting portion 110 and a carbon fiber heating rod connecting portion 120 connected to the power cord connecting portion 110; Axially passes through the wire passing hole 111 of the power cord connecting portion 110 ; the carbon fiber heating rod connecting portion 120 is provided with a connecting hole 121 communicating with the wire passing hole 111 along the carbon fiber heating rod connecting portion 120 axially.

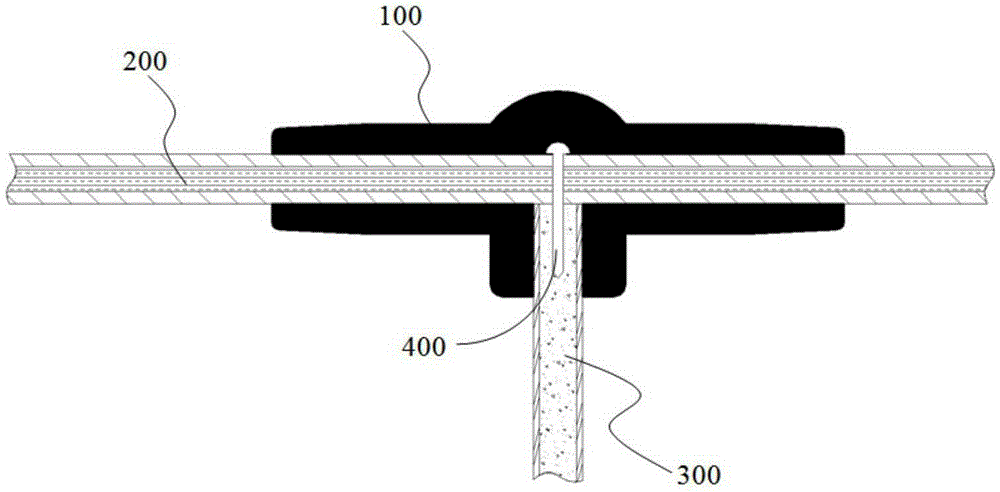

[0032] Moreover, the carbon fiber hot rail joint protection device 100 is integrally formed by injection molding. Specifically, after the power cord 200 and the carbon fiber heating rod 300 are connected by conductive connecting nails, the carbon fiber hot rail joint protection device 100 is injected...

Embodiment 2

[0037] Such as Figure 4 , Figure 5 As shown, it shows another preferred embodiment of the carbon fiber hot rail joint protection device of the present invention.

[0038] In this embodiment, the carbon fiber hot rail joint protection device 100 includes a power cord connecting portion 110 and a carbon fiber heating rod connecting portion 120 connected to the power cord connecting portion 110; Axially passes through the wire passing hole 111 of the power cord connecting portion 110 ; the carbon fiber heating rod connecting portion 120 is provided with a connecting hole 121 communicating with the wire passing hole 111 along the carbon fiber heating rod connecting portion 120 axially.

[0039] In addition, at least one first groove 130 is provided along the circumference of the wire passing hole 111 on the wall of the wire passing hole 111 in the power cord connecting portion 110 .

[0040] Preferably, two first grooves 130 are provided on the wall of the wire passing hole 11...

Embodiment 3

[0049] Such as Figure 4 , Figure 5 As shown, it shows another preferred embodiment of the carbon fiber hot rail joint protection device of the present invention.

[0050] In this embodiment, the carbon fiber hot rail joint protection device 100 includes a power cord connecting portion 110 and a carbon fiber heating rod connecting portion 120 connected to the power cord connecting portion 110; Axially passes through the wire passing hole 111 of the power cord connecting portion 110 ; the carbon fiber heating rod connecting portion 120 is provided with a connecting hole 121 communicating with the wire passing hole 111 along the carbon fiber heating rod connecting portion 120 axially.

[0051] In addition, at least one first groove 130 is provided along the circumference of the wire passing hole 111 on the wall of the wire passing hole 111 in the power cord connecting portion 110 .

[0052] Preferably, four first grooves 130 are provided on the hole wall of the wire passing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com