Underground heat storage tank

A heat storage tank and underground technology, which is used in heat storage equipment, energy storage, indirect heat exchangers, etc., can solve the problems of affecting the service life of the heat storage tank, large heat loss of the heat storage tank, and easy to be eroded by wind and sand. , to achieve the effect of reducing costs and expenses, reducing maintenance costs and facilitating system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

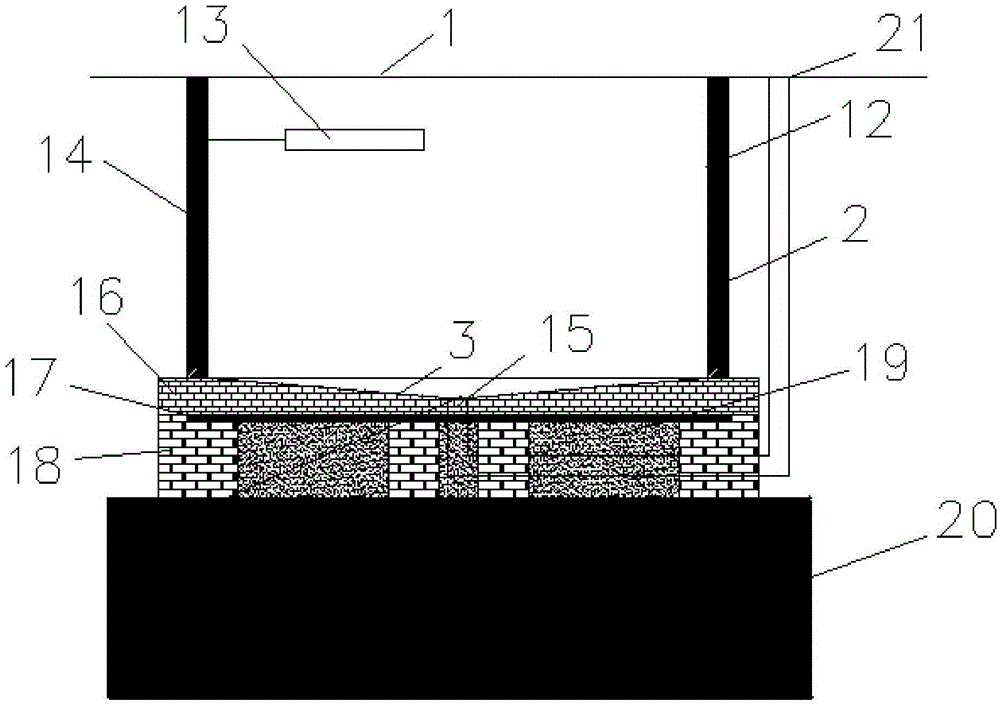

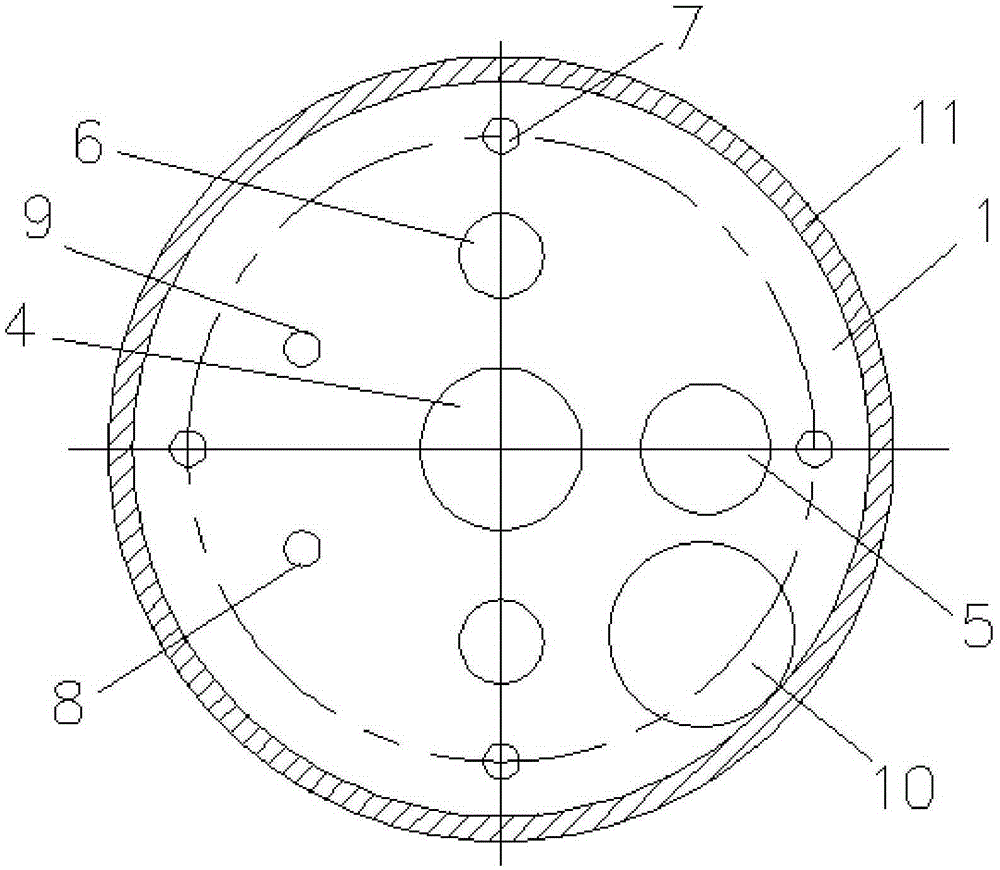

[0029] A buried heat storage tank, comprising a tank top cover 1, a tank wall 2 and a tank bottom 3, characterized in that the tank top cover 1 is provided with a molten salt pump port 4, a molten salt inlet 5, and a molten salt stirrer Port 6, electric heater port 7, liquid level gauge 8, thermometer 9, maintenance manhole 10, insulation layer A11;

[0030] The molten salt pump port 4 is located at the center of the tank top cover 1;

[0031] The molten salt stirrer port 6 is located on the longitudinal axis of the coordinate axis with the molten salt pump port 4 as the center, and is located above and below the molten salt pump port 4;

[0032] The electric heater port 7 is provided with 4, respectively located on the vertical and horizontal axes of the coordinate axis with the molten salt pump port 4 as the center of the circle, and is closest to the tank top cover 1;

[0033] The molten salt inlet 5 is located on the positive axis of the horizontal axis of the coordinate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com