Immersion ultrasonic measurement device and method for adjusting and measuring channel gap

An ultrasonic measurement and immersion technology, applied in measurement devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of local dispersion, inability to quantitatively enhance particle dispersion in real time, etc., to achieve precise control and strong guiding ability. , the effect of strong signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

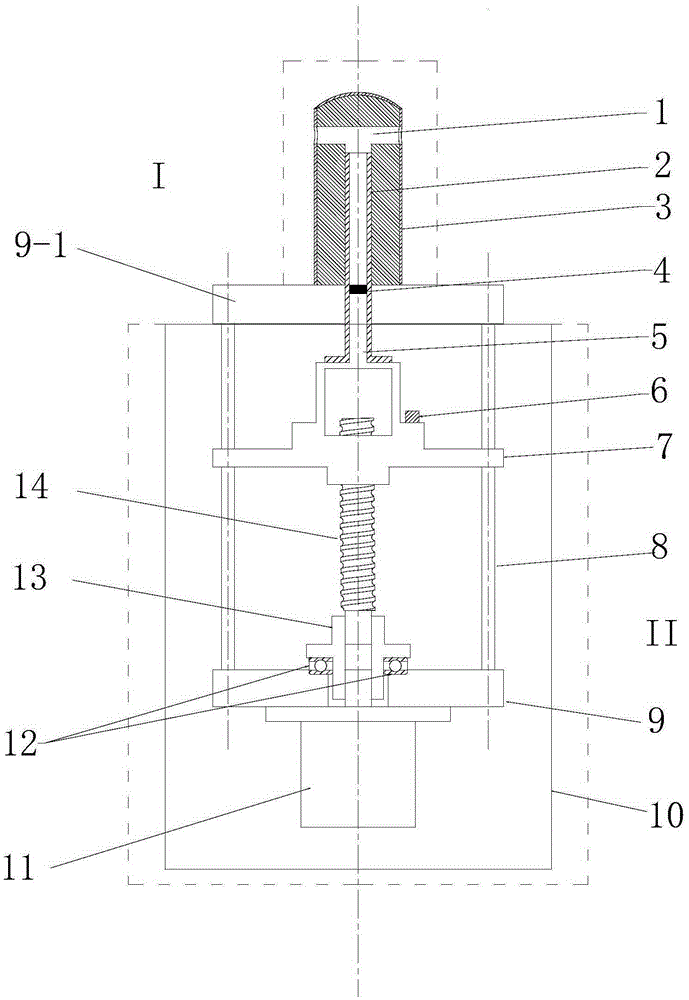

[0025] Such as figure 1 , 2 shown. The present invention is an immersion type ultrasonic measuring device for adjusting the measurement flow channel gap, comprising a measuring head I and an adjustable distance device II;

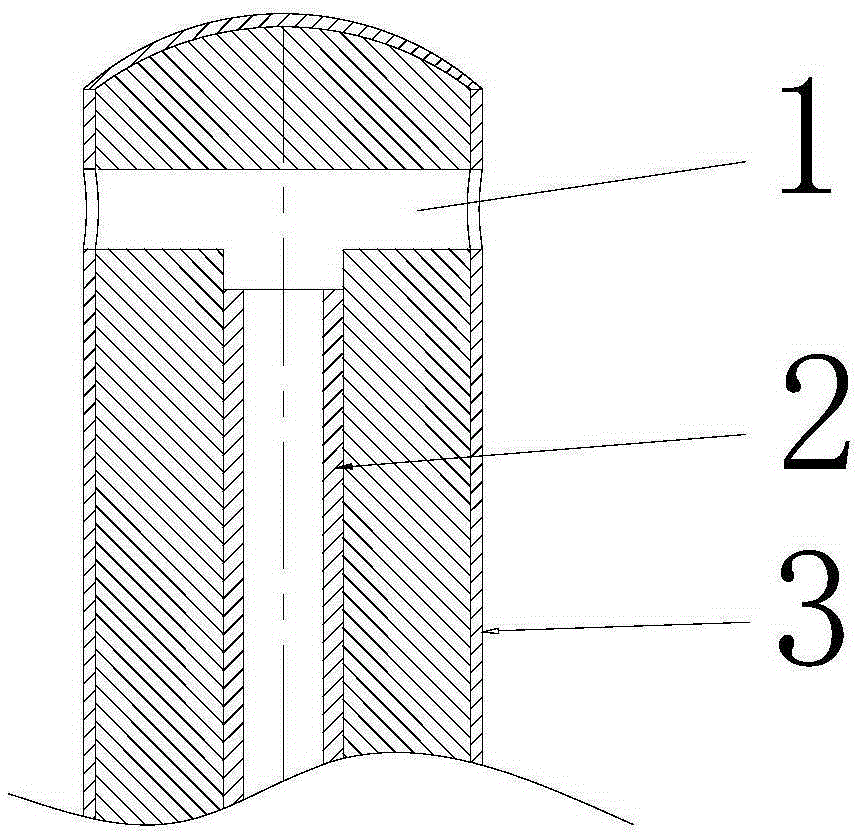

[0026] The measuring head 1 includes a measuring head body 3. At the end of the measuring head body 3, there is a slit flow channel 1 for the melt to pass through in the radial direction, and a probe channel is opened on one side of the slit flow channel 1. , the probe channel is provided with a buffer rod 2 with a cladding layer, and the ultrasonic probe 4 is fixedly installed in the buffer rod 2; the axis of the probe channel is perpendicular to the axis of the slit flow channel 1;

[0027] The buffer rod 2 is fixed on the adjustable distance device II, and the adjustable distance device II is provided with a displacement sensor 6; the adjustable distance device II drives the buffer rod 2 to move axially along the probe channel, so as to realize the ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com