A leak detection device

A technology of tightness detection and sealed box, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the acceleration and deceleration rate of fluid, etc. Hot tin seal is not tightly sealed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings.

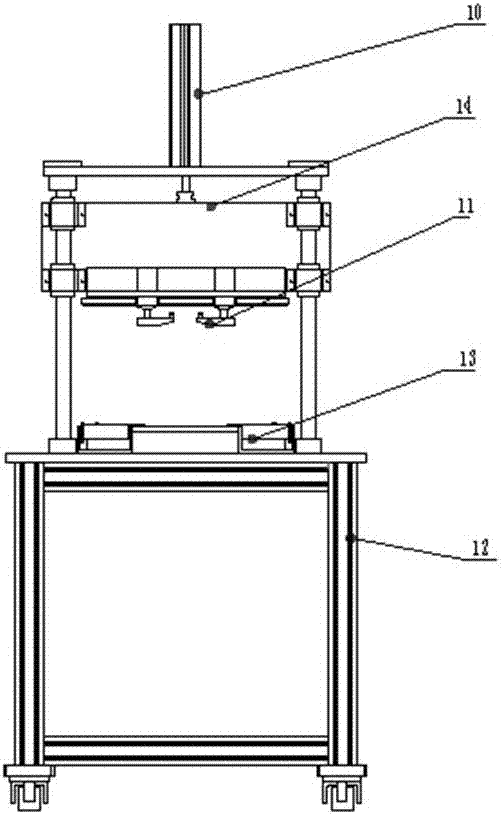

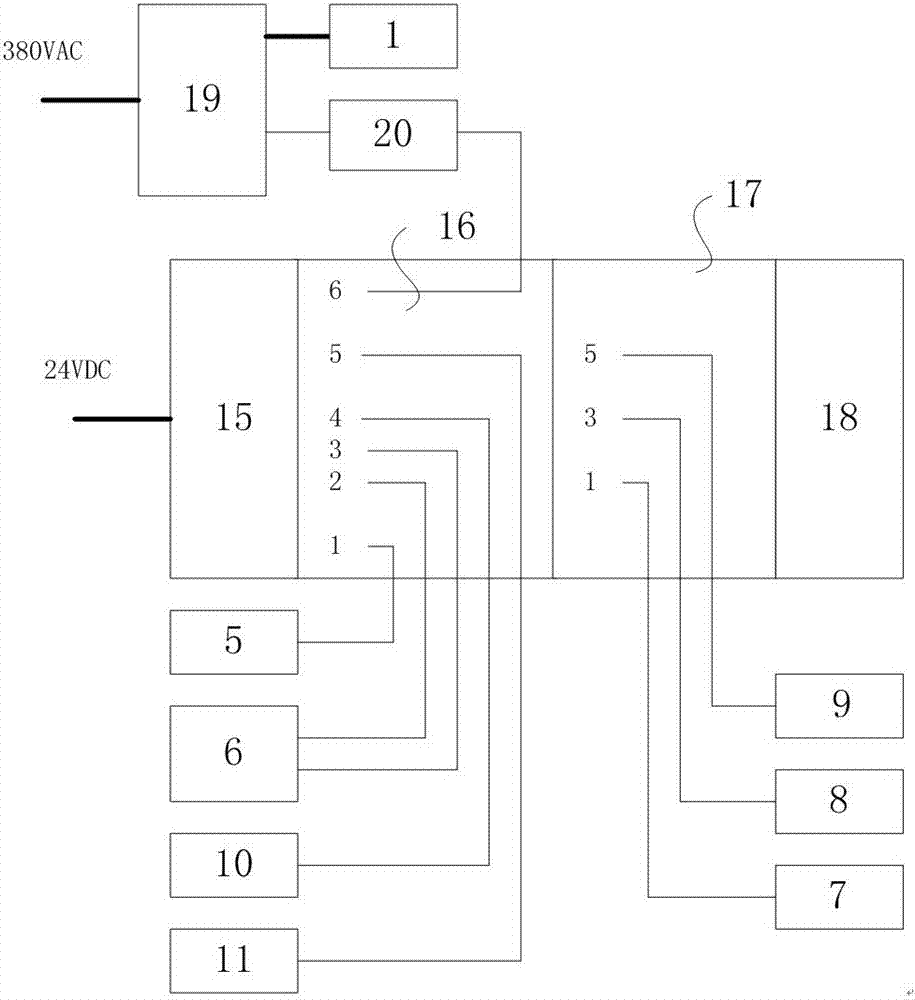

[0055] The detection device for iron box airtightness of the present invention includes: a detection mechanism and a control system.

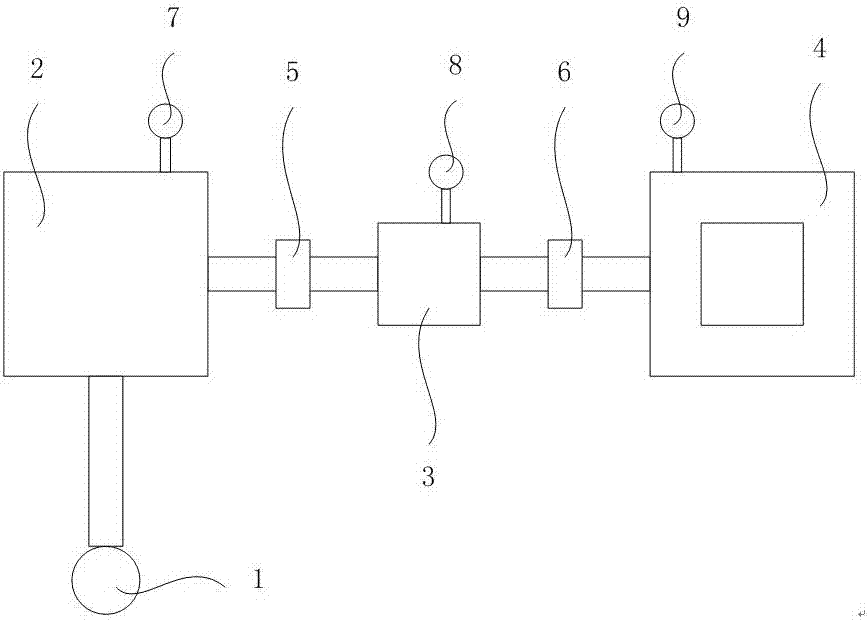

[0056] The detection mechanism includes: a vacuum pump 1, an air storage tank 2, a comparison tank 3, a sealed box 4, a first vacuum shut-off valve 5, a second vacuum shut-off valve 6, a first vacuum sensor 7, a second vacuum sensor 8, a first vacuum sensor Three vacuum sensor 9, upper and lower cylinder 10, positioning cylinder 11, frame 12.

[0057] The sealed box 4 includes: a sealed box base 13 and a sealed box upper cover 14 .

[0058] The connection relationship of the detection mechanism is:

[0059] The air outlet of the vacuum pump 1 is connected to the air inlet of the air storage tank 2 through a trachea.

[0060] The gas outlet of the gas storage tank 2 is connected to the air inlet of the comparison tank 3 through a trache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com