Method for evaluating damage accumulation inside steel structure thick plate

A steel structure and damage evolution technology, which is applied in the direction of testing material strength by applying stable tension/compression, and testing material strength by applying repetitive force/pulsation force, can solve the problem of difficult to accurately evaluate the damage accumulation of thick steel plate materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0094] A method for describing and evaluating internal damage accumulation of steel structural slabs, comprising the steps of:

[0095] Establish the elastic-plastic damage constitutive model for thick steel plates, deduce the incremental form of the stress component of the model, and compile the corresponding material subroutine for the incremental form;

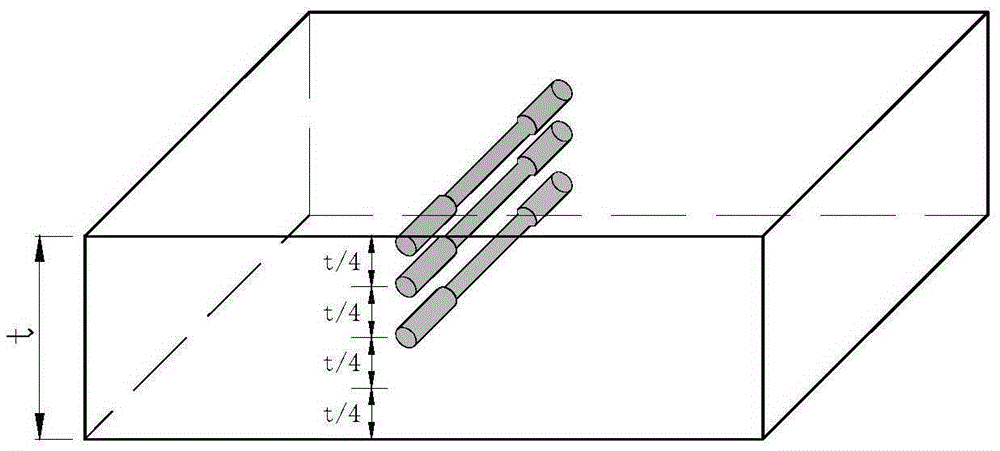

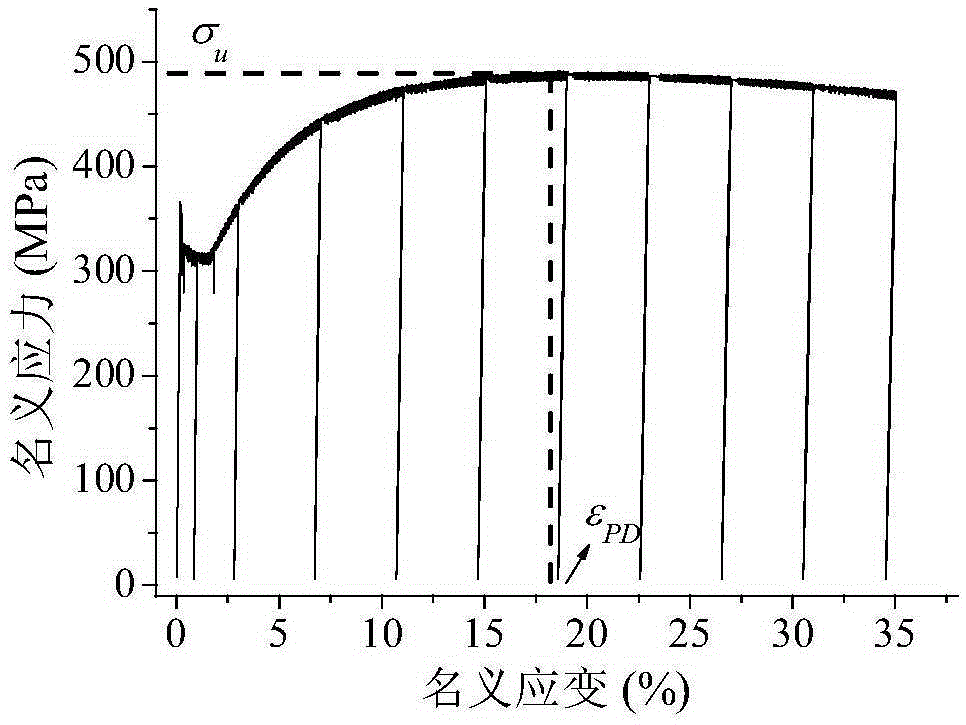

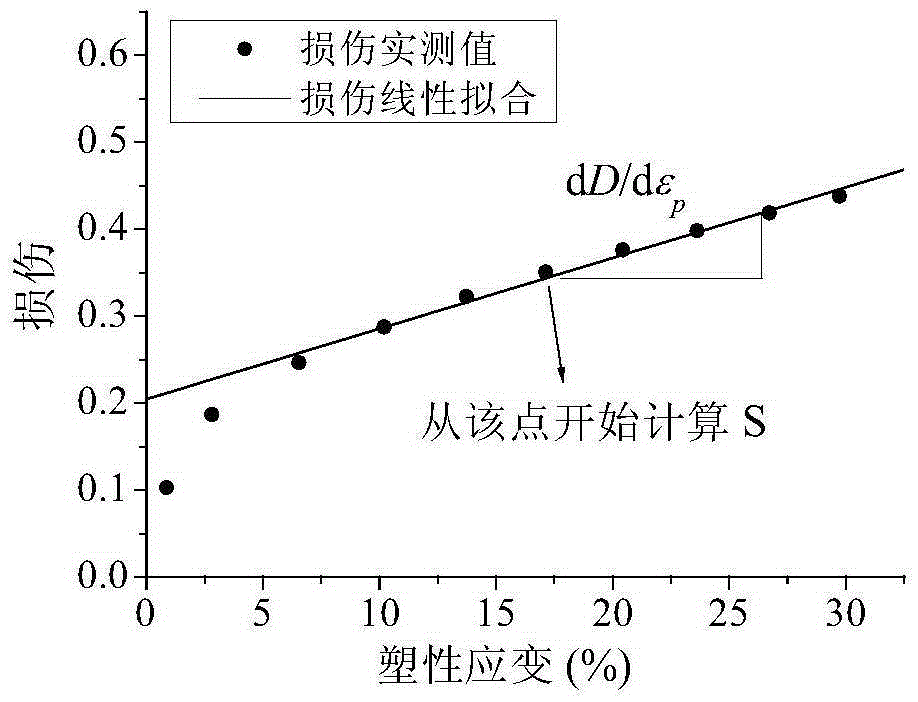

[0096] The thick steel plate is taken layer by layer along the thickness direction, and the elastoplastic parameters and damage parameters of each layer of material are determined through tests;

[0097] Establish the finite element model of the thick steel plate, introduce the compiled material subroutine into the finite element analysis, and assign different material properties to the material parameters of different layers;

[0098] The finite element model is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com