{0><}0{>Method for measuring contents of gold and silver in gold mud sample by virtue of fire assay

A technology of fire testing gold and medium gold content, which can solve the problems such as the difference in the properties of gold mud materials in the production process by removing certain components, weighing, investigating stages/state changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Include the following steps:

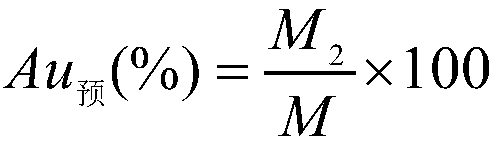

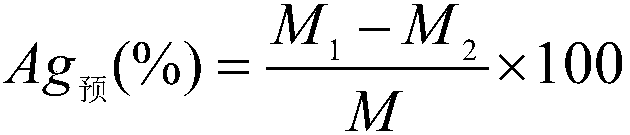

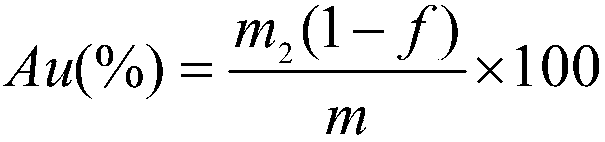

[0064] (1) Prediction of gold and silver content

[0065] Weigh 100mg of the sample, the mass is M, wrap 14g of lead foil, put it into the ash dish that has been preheated at 950°C for 30 minutes, carry out ash blowing at 880°C, after 30 minutes of ash blowing, take out the ash dish to cool, and then put Take it out and hammer it into thin slices, weigh and record its mass M 1 Add 1.5 times the amount of silver to observe the color of the combined grains, wrap 5 grams of lead foil and carry out ash blowing again, take out the ash dish to cool after the ash blowing ends; then take out the gold and silver combined grains and hammer them into thin slices, put them in a 25 ml colorimetric tube, add (1 +5) 10 ml of dilute nitric acid, boil in a water bath for 40 minutes, pour out the acid solution, then add 10 ml of 80°C (1+1) nitric acid, continue to boil in a water bath for 40 minutes, pour out the acid solution, and wash the gold particles ...

Embodiment 2

[0110] Include the following steps:

[0111] (1) Prediction of gold and silver content

[0112] Weigh 100 mg of the sample, the mass is M, wrap 15 grams of lead foil, put it into the ash dish that has been preheated at 980°C for 25 minutes, carry out ash blowing at 900°C, after 25 minutes of ash blowing, take out the ash dish to cool, and then put the gold and silver particles Take it out and hammer it into thin slices, weigh and record its mass M 1 Add 2.3 times the amount of silver to observe the color of the combined grains, wrap 6 grams of lead foil and carry out ash blowing again, take out the ash dish to cool after the ash blowing ends; then take out the gold and silver combined grains and hammer them into thin slices, put them in a 25 ml colorimetric tube, add (1 +5) 13 ml of dilute nitric acid, boil in a water bath for 35 minutes, pour out the acid solution, then add 13 ml of 90°C (1+1) nitric acid, continue to boil in a water bath for 35 minutes, pour out the acid so...

Embodiment 3

[0157] Include the following steps:

[0158] (1) Prediction of gold and silver content

[0159] Weigh 100 mg of the sample, the mass is M, wrap 16 grams of lead foil, put it into the ash dish that has been preheated at 1000°C for 20 minutes, carry out ash blowing at 920°C, after 20 minutes of ash blowing, take out the ash dish to cool, and then mix the gold and silver particles Take it out and hammer it into thin slices, weigh and record its mass M 1 Add 3.0 times the amount of silver to observe the color of the combined grains, wrap 7 grams of lead foil and carry out ash blowing again, take out the ash dish to cool after the ash blowing ends; then take out the gold and silver combined grains and hammer them into thin slices, put them in a 25 ml colorimetric tube, add (1 +5) 15 ml of dilute nitric acid, boil in a water bath for 30 minutes, pour out the acid solution, then add 15 ml of 100°C (1+1) nitric acid, continue to boil in a water bath for 30 minutes, pour out the acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com