Negative-pressure rapid butting device for sample feeding of micro-fluidic chip

A technology of microfluidic chip and docking device, which is applied in the direction of analyzing materials and instruments, and can solve the problems that gas path joints cannot be realized, and achieve high sealing performance and improve sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

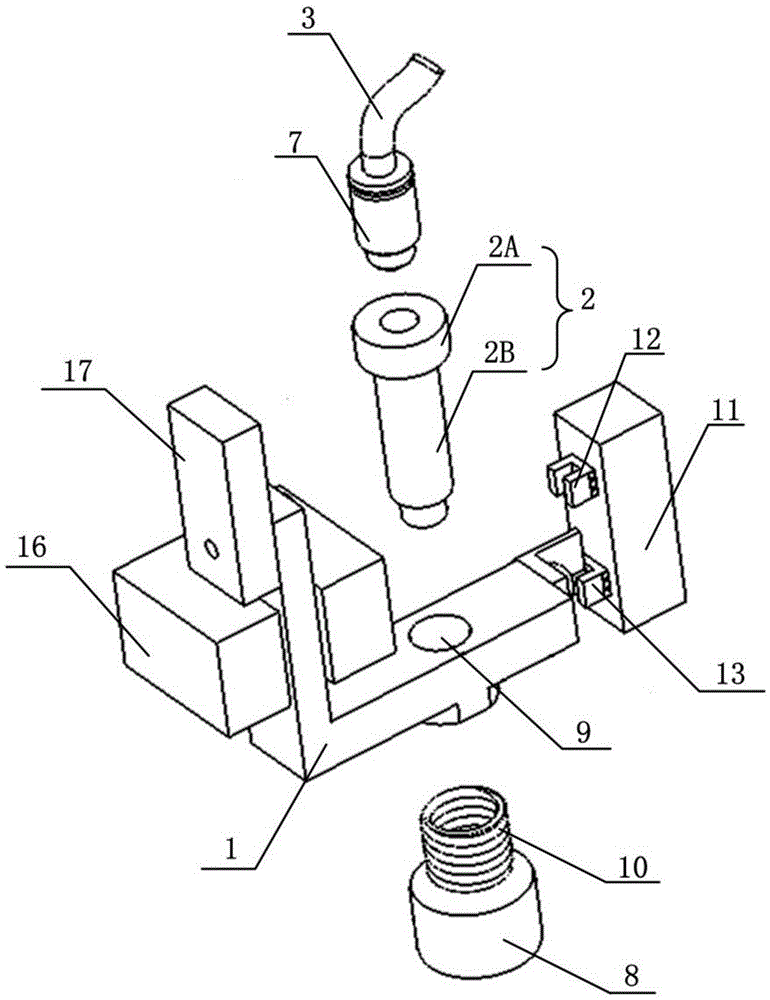

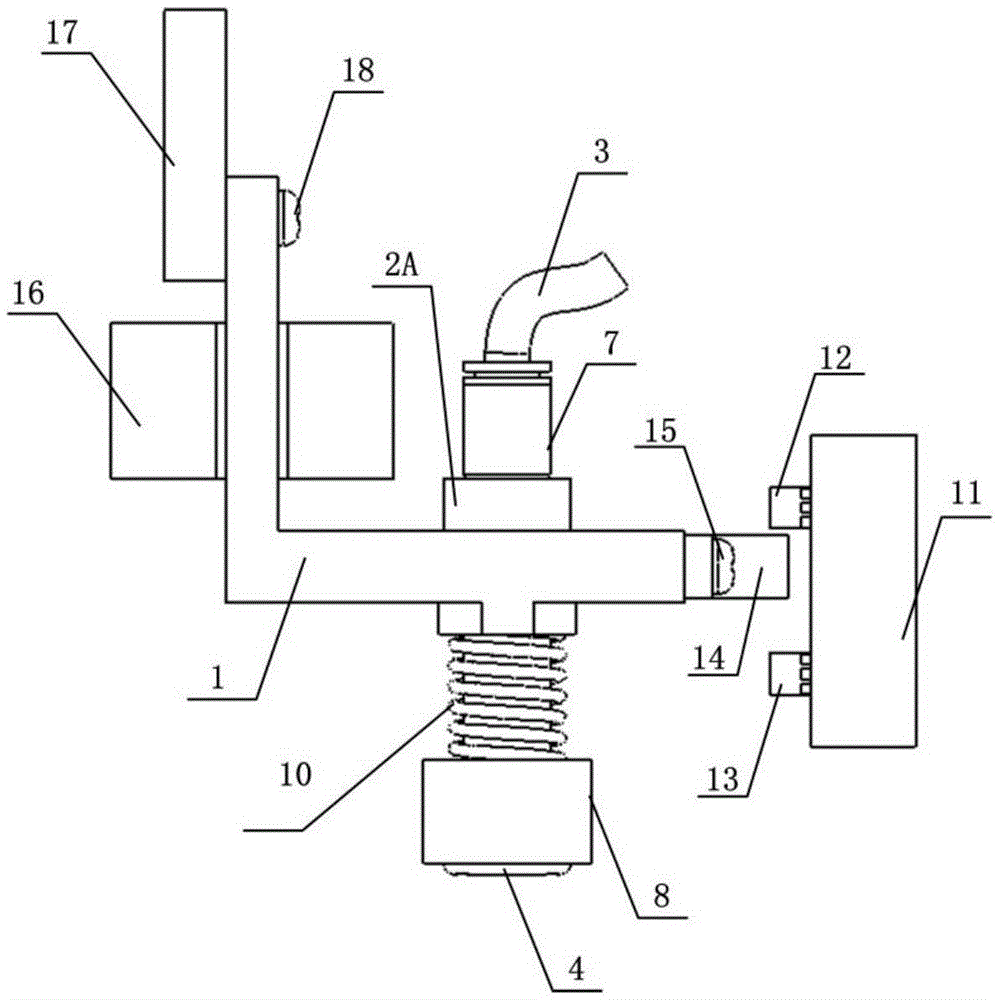

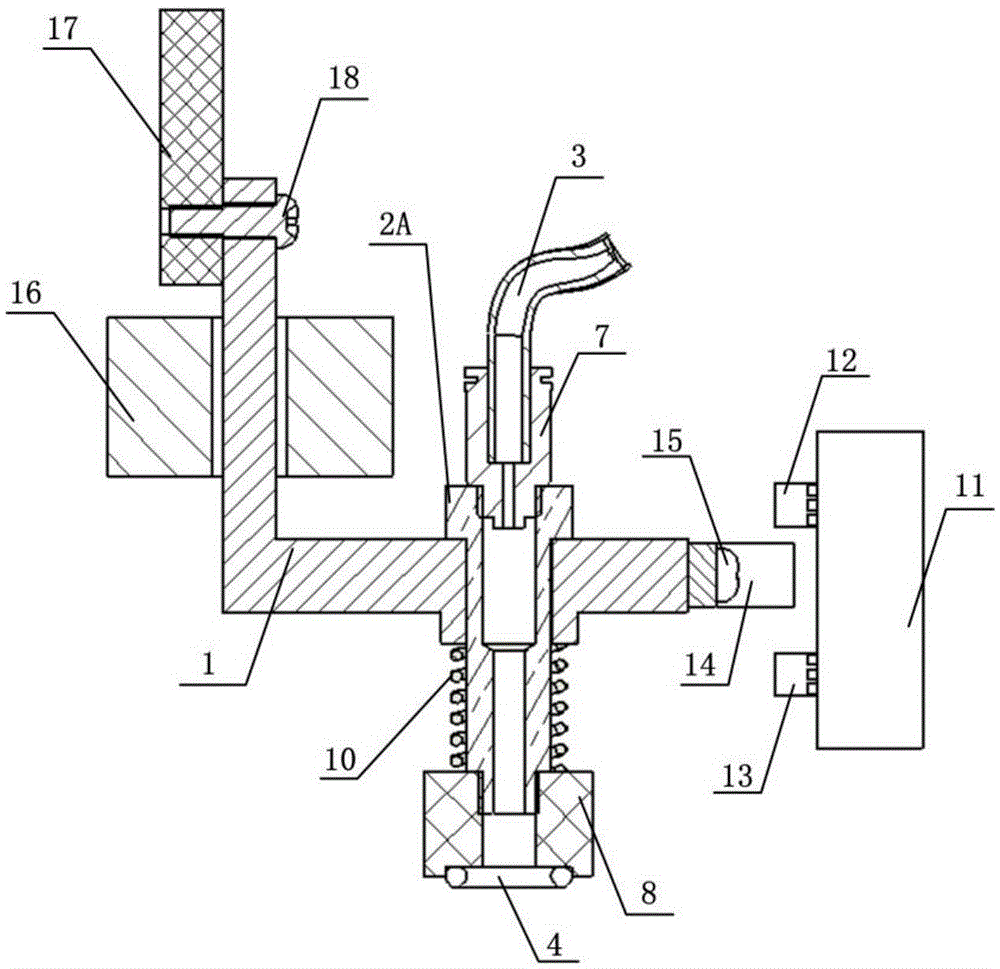

[0042] Such as Figure 1 to Figure 3 As shown, the negative pressure fast docking device for microfluidic chip injection according to the present invention includes: a driving part 1, which can reciprocate in the vertical direction; The pipeline 3 that enters the negative pressure, and the lower end is connected with the elastic sealing member 4; the follower 2 is connected to the active member 1, and driven by it, it moves downward to squeeze the microfluidic chip 5 to be docked under negative pressure. After the negative pressure is connected, it is withdrawn, wherein both the follower 2 and the sealing member 4 are of hollow structure; the hollow structure of the sealing member 4 is aligned with the air hole 6 when squeezed.

[0043]The negative pressure rapid docking device for microfluidic chip injection provided by the present invention, through the active part 1 capable of reciprocating vertically and the driven part 2 connected thereto, the driven part 2 and the sealin...

Embodiment 2

[0053] On the basis of Example 1, this example provides a method for rapid negative pressure insertion and withdrawal of samples into the microfluidic chip 5 using the negative pressure rapid docking device of Example 1.

[0054] Negative pressure docking fast access, before negative pressure docking, such as Figure 4a to Figure 4b As shown, the active part 1 is located at the position of the reset position switch 12, the microfluidic chip 5 to be docked under negative pressure is ready, the driving part 17 drives the active part 1, and drives the gas circuit joint 7 and the driven part 2 through the elastic part 10 , the interface piece 8 , the sealing piece 4 and the position switch triggering device 14 move toward the microfluidic chip 5 in the vertical direction. Movement to a certain moment, the sealing member 4 and the air hole 6 of the microfluidic chip 5 begin to contact, due to the obstruction of the microfluidic chip 5, the follower 2, the gas path joint 7, the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com