Polymeric drug delivery system for treating surgical complications

A polymer and drug technology, applied in the field of polylactic acid, can solve the problems of sternal wound infection and the incidence of mediastinitis are not very effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0196] Embodiment 1: the preparation of polymer-drug powder

[0197] Tyrosine polyesteramide (P22-27.5) powders containing rifampicin (10%) and minocycline (10%) drugs were prepared by grinding polymer films. Polymer films containing rifampicin and minocycline were prepared by solvent casting. Briefly, 8 g of tyrosine polyester amide P22-27.5 were dissolved in 36 ml of THF. In separate vials, 1 g of rifampicin and 1 g of minocycline were dissolved in 4 ml of methanol. The two solutions were mixed and poured into TEFLON pans (10 cm diameter x 1.9 cm depth). The solution was left in a fume hood at room temperature for 16-18 hours to evaporate the solvent. Place the dish in a 50°C oven under vacuum for 24 hours. The formulation foamed and formed a film. The film was crushed into a powder using a small mixer. As a result, 8.7 g of tyrosine polyester amide polymer powders containing 10% each of rifampicin and minocycline in the MW range of 6 kDa to 70000 kDa were prepared by ...

Embodiment 2

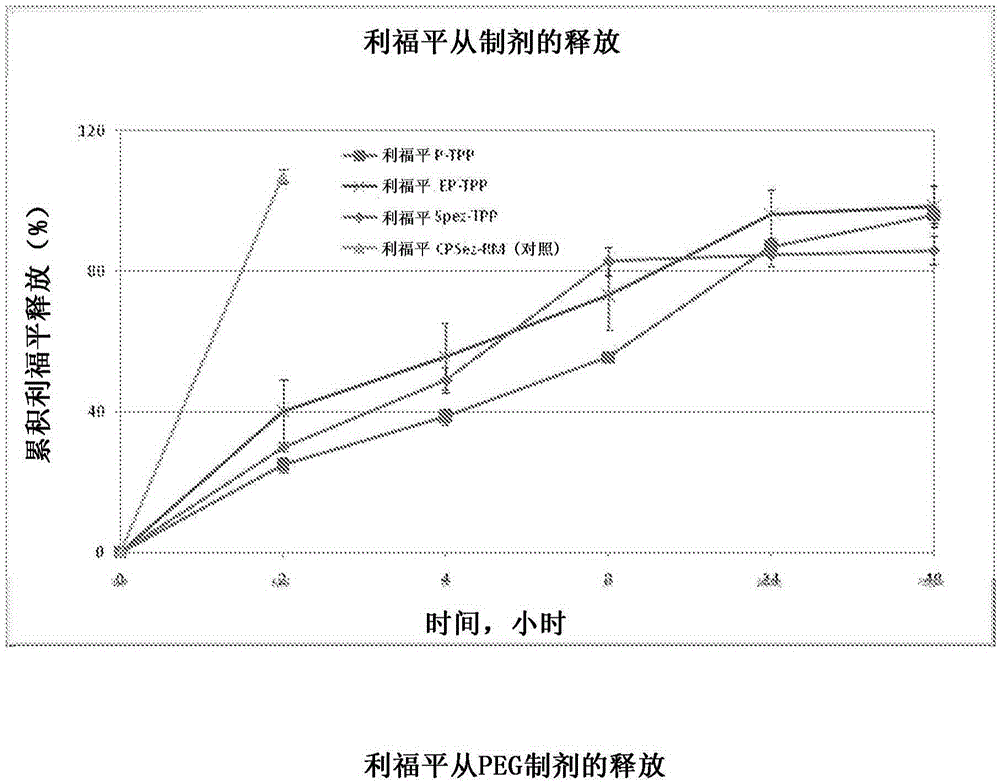

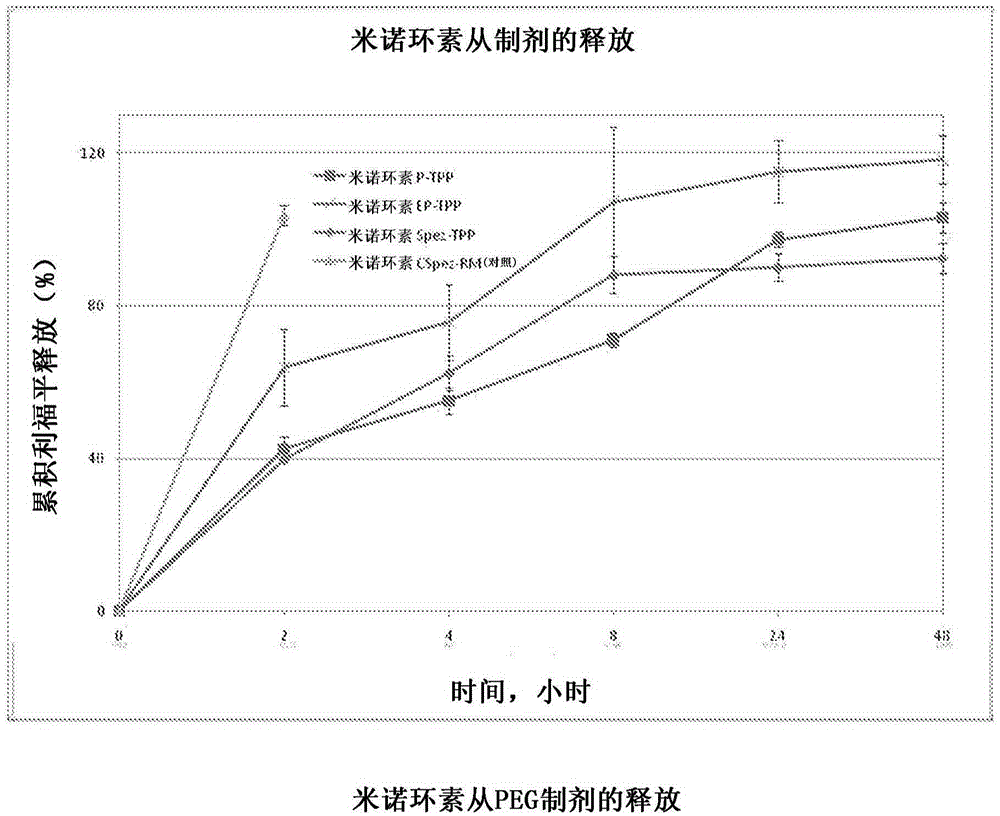

[0198] Example 2: Preparation of PEG-polymer formulations

[0199] Various formulations were prepared in which P22-27.5-drug powder was combined with various ratios of PEG (MW400) to obtain various polymer-drug powder combinations. Table 2 below shows the different combinations.

[0200] Table 2: P22-27.5-rifampicin-minocycline formulations with PEG400

[0201] #

Embodiment 3

[0202] Embodiment 3: Viscosity determination

[0203] The viscosity of the oily (lubricating oil) formulations was measured on a Brookfield viscometer (Model DVII+Pro, Brookfield Engineering Lab Inc., Middleboro, MA) equipped with a thermometer and 4 different spindles. Formulation #5 mentioned in Table 2 was taken into a 20ml scintillation vial and the viscosity was measured using spindle #63 at a shear rate of 10 rpm under ambient conditions. The viscosity of the formulation is 2230-2260 cp (centipoise).

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com