concrete bolt

A concrete and bolt technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve problems such as failure, and achieve the effect of reducing brittle fracture tendency, reducing brittle fracture tendency, and avoiding stress peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

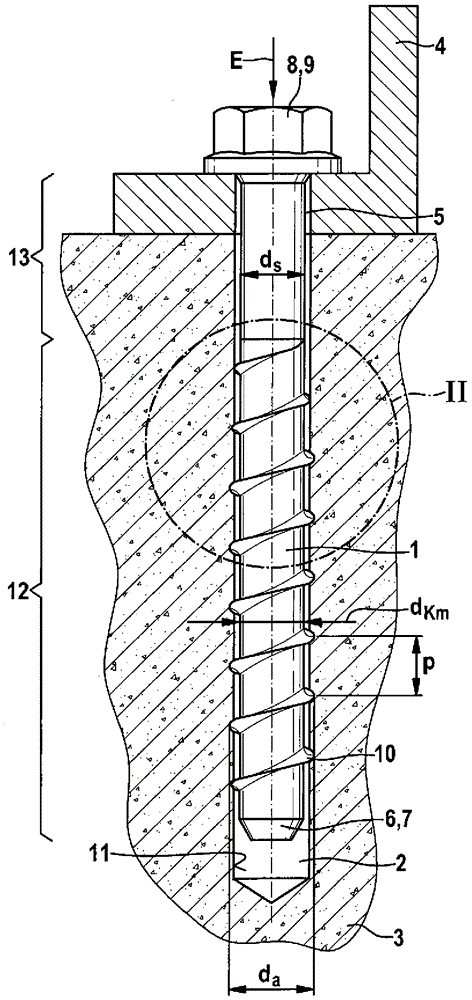

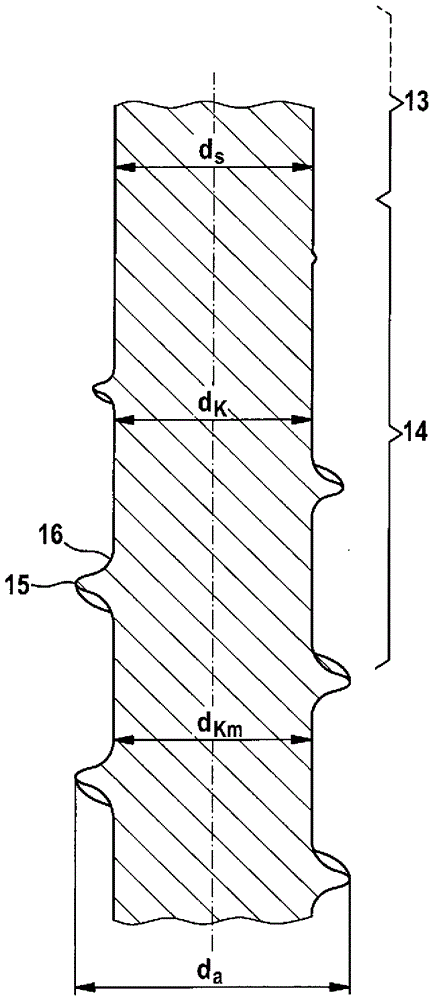

[0017] The thread-cut concrete bolt 1 according to the invention shown in the drawing is intended to be screwed into a pre-drilled hole 2 in a foundation 3 made of concrete, a wall or another mineral material. The concrete bolt 1 is screwed into the borehole 2 without dowels or other auxiliary measures, while an internal thread is automatically cut in the foundation 3 and serves to fix the object 4 in the form of a steel angle bracket. For this purpose, the concrete bolt 1 is inserted through the through-hole 5 of the body 4 before being screwed into the foundation 3 . figure 1 Shows the fully docked state. The concrete bolts 1 together with the foundation 3 form the fixture.

[0018] The concrete screw 1 has a frusto-conical constriction 6 at the front screw end 7 in the insertion direction E and has a tool engagement measure 8 at the rear screw end 9 . In the exemplary embodiment shown, the tool action measure 8 is an external hexagon, this head shape is not mandatory.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap