High-carbon duplex stainless steel material and preparation method thereof

A duplex stainless steel, high-carbon technology, used in manufacturing tools, heat treatment equipment, casting and molding equipment, etc., can solve the problem of wear resistance, pressure resistance can not meet the requirements, hardness and tensile strength are lower than requirements, and the tendency to crack is large. and other problems, to achieve the effect of excellent comprehensive service performance, improvement of anti-wear and anti-corrosion performance, and reduction of brittle fracture tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

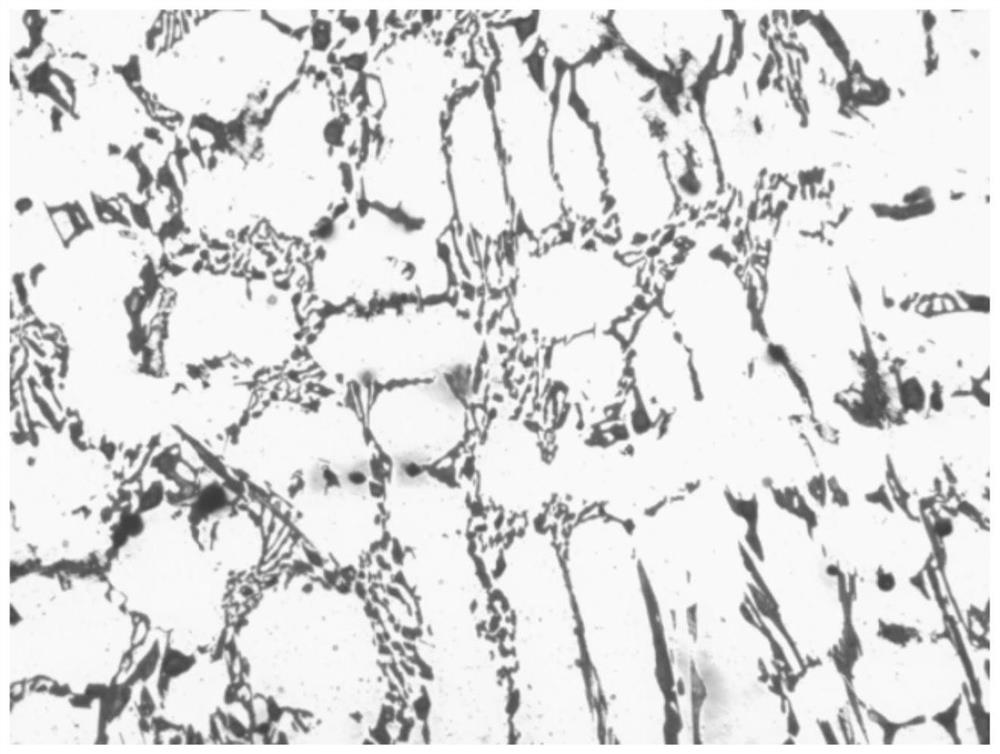

Image

Examples

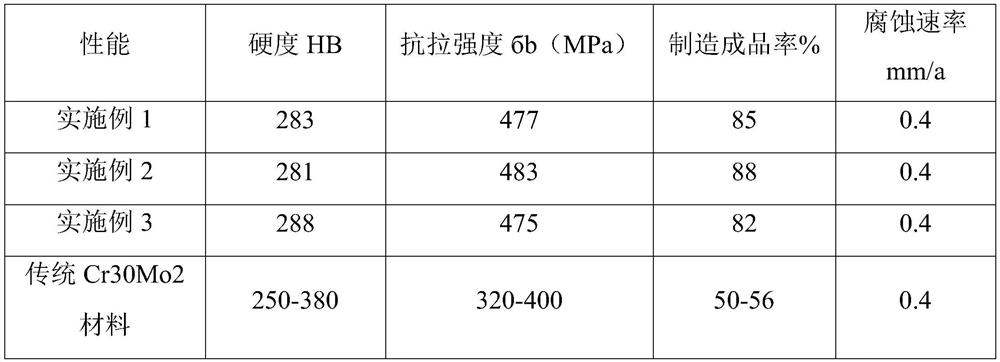

Embodiment 1

[0031] A high-carbon duplex stainless steel material, including the following chemical elements in mass percentage:

[0032] C: 0.8%, Si: 1.12%, Mn: 0.4%, P: 0.04%, S: 0.03%, Cr: 28.0%, Ni: 0.38%, V: 0.136%, Mo: 1.7%, Nb: 0.14%, and the balance of Fe.

[0033] The preparation method of the above-mentioned high-carbon duplex stainless steel material comprises the following steps:

[0034] a. Weigh scrap steel, ferrochrome, ferromolybdenum, ferromanganese, nickel plate, ferrovanadium and ferroniobium according to the proportion of the above chemical elements in high carbon duplex stainless steel materials; Add ferromanganese and ferromanganese into the intermediate frequency furnace in turn, heat up to 1620°C for heating and melting, after the raw materials are melted by 40%, add 3# Yupont alloy liquid purifying agent to continue heating and melting, after melting, add ferrovanadium with a block size of 25mm and ferroniobium, melted and then released from the furnace to obtain...

Embodiment 2

[0038] A high-carbon duplex stainless steel material, including the following chemical elements in mass percentage:

[0039] C: 0.914%, Si: 0.493%, Mn: 0.265%, P: 0.037%, S: 0.015%, Cr: 29.5%, Ni: 0.222%, V: 0.142%, Mo: 1.776%, Nb: 0.145%, and the balance of Fe.

[0040] The preparation method of the above-mentioned high-carbon duplex stainless steel material comprises the following steps:

[0041] a. Weigh scrap steel, ferrochrome, ferromolybdenum, ferromanganese, nickel plate, ferrovanadium and ferroniobium according to the proportion of the above chemical elements in high carbon duplex stainless steel materials; Add ferromanganese and ferromanganese into the intermediate frequency furnace in turn, heat up to 1650°C for heating and melting, after the raw materials are melted by 50%, add 3# Yupont alloy liquid purifying agent to continue heating and melting, after melting, add ferrovanadium with a block size of 25mm and ferroniobium, melted and then released from the furnace ...

Embodiment 3

[0045] A high-carbon duplex stainless steel material, including the following chemical elements in mass percentage:

[0046] C: 1.1%, Si: 0.581%, Mn: 0.227%, P: 0.32%, S: 0.022%, Cr: 32.0%, Ni: 0.17%, V: 0.145%, Mo: 2.2%, Nb: 0.15%, and the balance of Fe.

[0047] The preparation method of the above-mentioned high-carbon duplex stainless steel material comprises the following steps:

[0048] a. Weigh scrap steel, ferrochrome, ferromolybdenum, ferromanganese, nickel plate, ferrovanadium and ferroniobium according to the proportion of the above chemical elements in high carbon duplex stainless steel materials; Add ferromanganese and ferromanganese into the intermediate frequency furnace in turn, heat up to 1680°C for heating and melting, after the raw materials are melted by 60%, add 3# Yupont alloy liquid purifying agent to continue heating and melting, after melting, add ferrovanadium with a block size of 25mm and ferroniobium, melted and then released from the furnace to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com