Sweet potato peeling device

A technology of red glutinous rice and leather case, which is applied in the fields of grain pod removal, grain degermination, and grain processing, etc., can solve the problems of equipment blockage, complicated operation procedures, and heavy labor burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

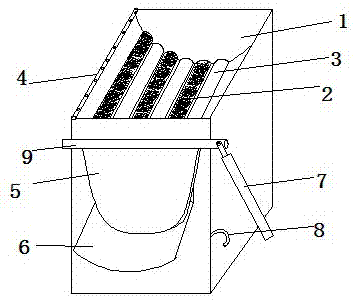

[0014] The reference signs in the description of the drawings are: peeling box 1, brush roller 2, drive roller 3, pressure water spray pipe 4, rotating baffle plate 5, feeding trough 6, handle 7, locking groove 8, rotating shaft 9 .

[0015] Such as figure 1 As shown, the technical solution provides a sweet potato peeling device, including a peeling device and a discharge device, and the peeling device includes a peeling box 1, and the inside of the peeling box 1 is an arc structure, and the inside of the peeling box 1 is equipped with 4 Root brush roller 2 and 4 transmission rollers 3 with smooth surface. Brush rollers 2 and drive rollers 3 are arranged alternately along the inner surface of the peeling box 1 . The right ends of the brush roller 2 and the driving roller 3 are respectively sheathed with mutually meshing gears, wherein the driving roller 3 is powered by a motor to drive the brush roller 2 to rotate in reverse. In order to peel the sweet potato better, the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com