A method for separating and recovering aluminum, potassium and ammonium from a mixed solution containing aluminum sulfate, potassium sulfate and ammonium sulfate

A technology for separating, recovering and mixing solutions, which is applied in the fields of alkali metal sulfite/sulfite, chemical instruments and methods, ammonium sulfate, etc., and can solve the problems of unreasonable recovery and utilization of potassium and sodium, unsatisfactory precipitation efficiency, reagents, etc. Large consumption and other issues, to achieve efficient separation and recycling, improve resource utilization, and save the separation and recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

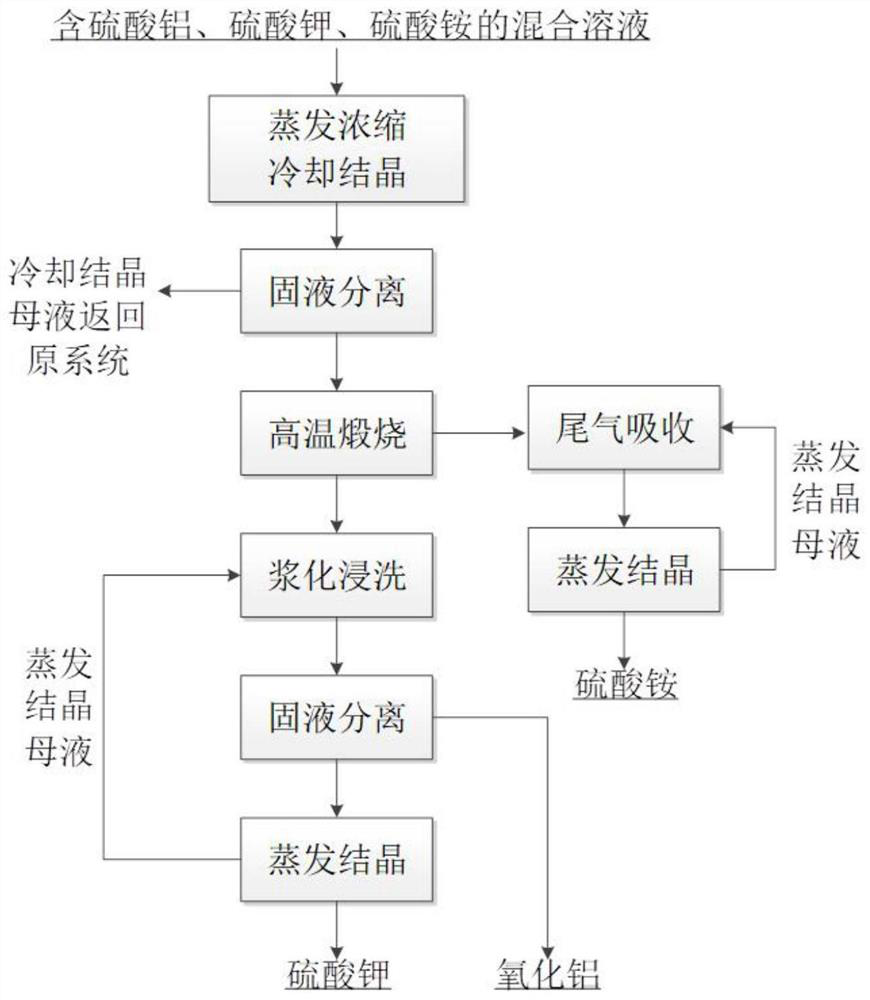

[0084] The present embodiment provides a method for separating and recovering aluminum, potassium and ammonium from a mixed solution containing aluminum sulfate, potassium sulfate and ammonium sulfate, which comprises the following steps:

[0085] (1) The mixed solution containing aluminum sulfate, potassium sulfate and ammonium sulfate is evaporated and concentrated at 85°C, and the total concentration of potassium alum and ammonium alum is obtained as a concentrated solution of 15wt%. The cooling rate of min carries out cooling crystallization, obtains the mixed crystal of potassium alum and ammonium alum;

[0086] (2) filtering the mixed crystal obtained in step (1) and the cooling crystallization mother liquor to realize solid-liquid separation;

[0087] (3) calcining the mixed crystals separated in step (2) at 850°C at high temperature for 3 hours, and slurrying and rinsing the high-temperature calcined product for 3 hours with stirring at 70°C, The mass ratio of the vol...

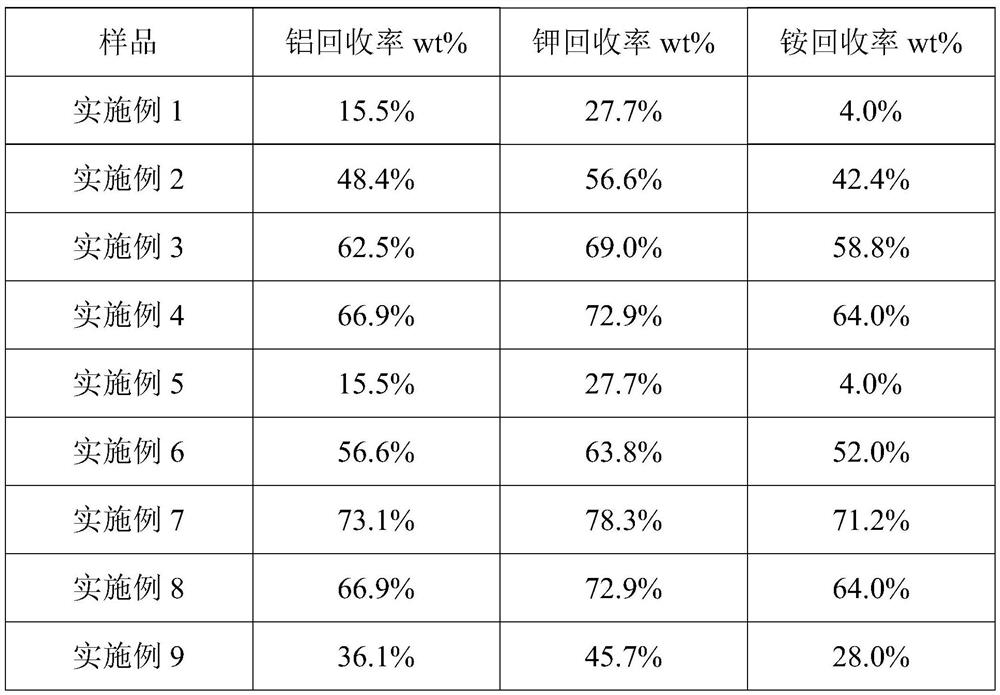

Embodiment 2

[0091] This embodiment provides a method for separating and recovering aluminum, potassium and ammonium from a mixed solution containing aluminum sulfate, potassium sulfate and ammonium sulfate, except that the mixed solution containing aluminum sulfate, potassium sulfate and ammonium sulfate is carried out in step (1). Evaporated and concentrated, the total concentration that obtains potassium alum and ammonium alum is replaced with the concentrated solution of 25wt%, all the other are identical with embodiment 1.

Embodiment 3

[0093] This embodiment provides a method for separating and recovering aluminum, potassium and ammonium from a mixed solution containing aluminum sulfate, potassium sulfate and ammonium sulfate, except that the mixed solution containing aluminum sulfate, potassium sulfate and ammonium sulfate is carried out in step (1). Evaporated and concentrated, the total concentration that obtains potassium alum and ammonium alum is replaced with the concentrated solution of 35wt%, all the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com