Sand making machine

A technology of sand making machine and crushing chamber, which is applied in the direction of grain processing, etc., which can solve the problems of not being able to meet the discharge requirements of different sand making speeds, and achieve the effects of low cost, small kinetic energy, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

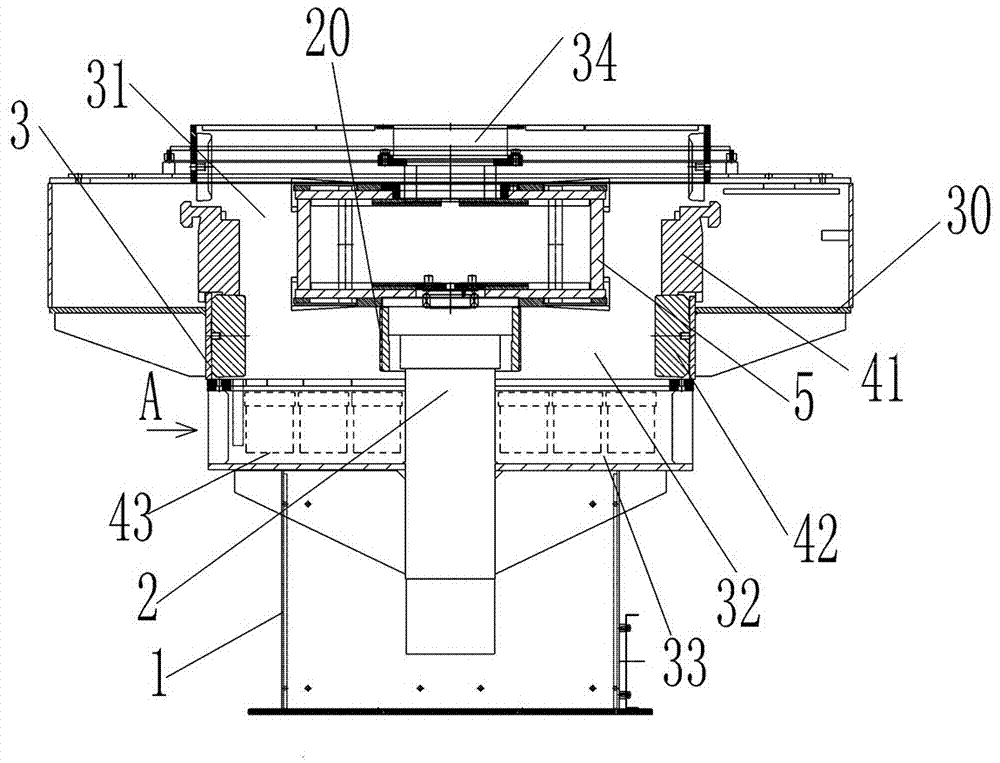

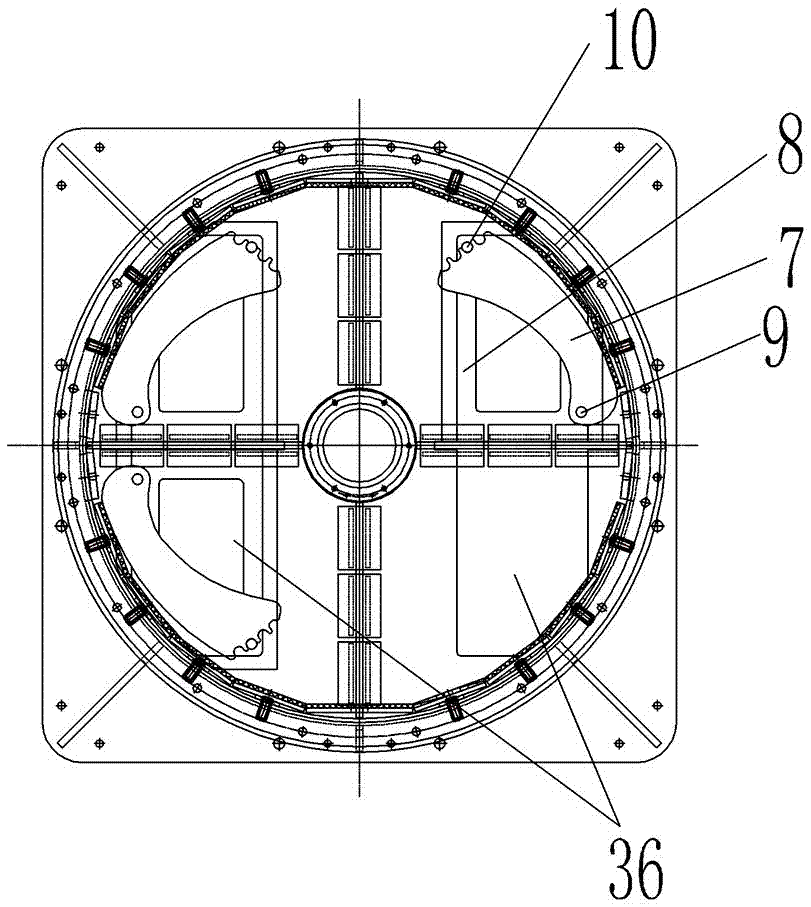

[0028] Such as Figure 1 to Figure 5 As shown, an embodiment of a sand making machine with a discharge port adjustment device, the sand making machine in this embodiment includes a chassis 1, and a crushing chamber assembly 3 is arranged on the chassis 1, and the crushing chamber assembly 3 A spindle assembly 2 extending vertically is arranged in the middle, and a rotor 5 is arranged on the top of the spindle assembly 2 .

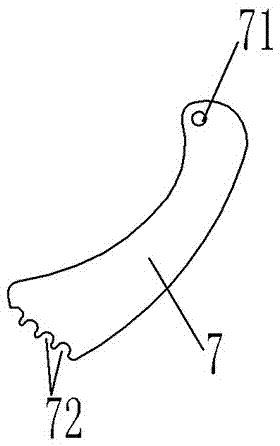

[0029] The crushing chamber assembly 3 includes a housing 30 with a crushing chamber. The upper part of the housing 30 is provided with a feed port 34 communicating with the crushing chamber. The upper part of the crushing chamber is a primary crushing area 31 corresponding to the rotor. The circumferential direction of the housing 30 is A primary anti-friction lining 41 arranged around the rotor 5 is provided on the side wall. The lower part of the crushing chamber is a blanking area 33, and the bottom plate 3 of the housing 30 is provided with a discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com