Progressive die for safety belt fixing nut stiffening plate

A technology for fixing nuts and reinforcing plates, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of unstable parts quality, potential safety hazards in operation, high machine tool occupancy rate, etc., achieve high repeatable assembly accuracy, reduce mold Difficulty of assembly, effect of improving part quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

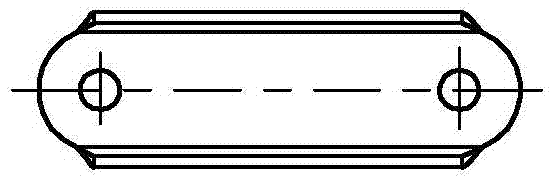

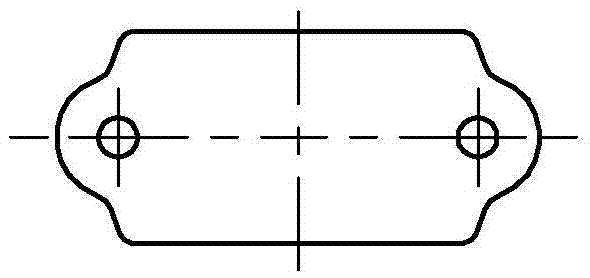

[0029] Embodiment 1: A safety belt fixing nut reinforcement plate progressive die, including an upper die assembly, a lower die assembly and a stripper plate 9, the upper die assembly includes an upper die base 4, and an upper die base The connected upper die backing plate 6 and the punch fixing plate 8 connected with the upper die backing plate are provided with two punching punches 12, one local shape punching punch 22 and 1 bending-cutting punch 11.

[0030] The lower mold assembly includes a lower mold base 1, a lower mold backing plate 14 connected with the lower mold base and an integral die 2 connected with the lower die backing plate. 2 punching die holes 201 that cooperate with the 2 punching punches of the upper die assembly, 1 local shape punching die hole 202 that cooperates with the local shape punching die of the upper die assembly and the One bending-cutting die groove 203 for the bending-cutting punch of the upper die assembly. Described bending-cutting die g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com