Automatic wire segmentation shearing-bending forming machine

An automatic segmenting and forming machine technology, applied in the field of building materials processing equipment, can solve the problems of large equipment investment, cumbersome operation, and affecting processing efficiency, and achieve the effects of improving efficiency, simple operation, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

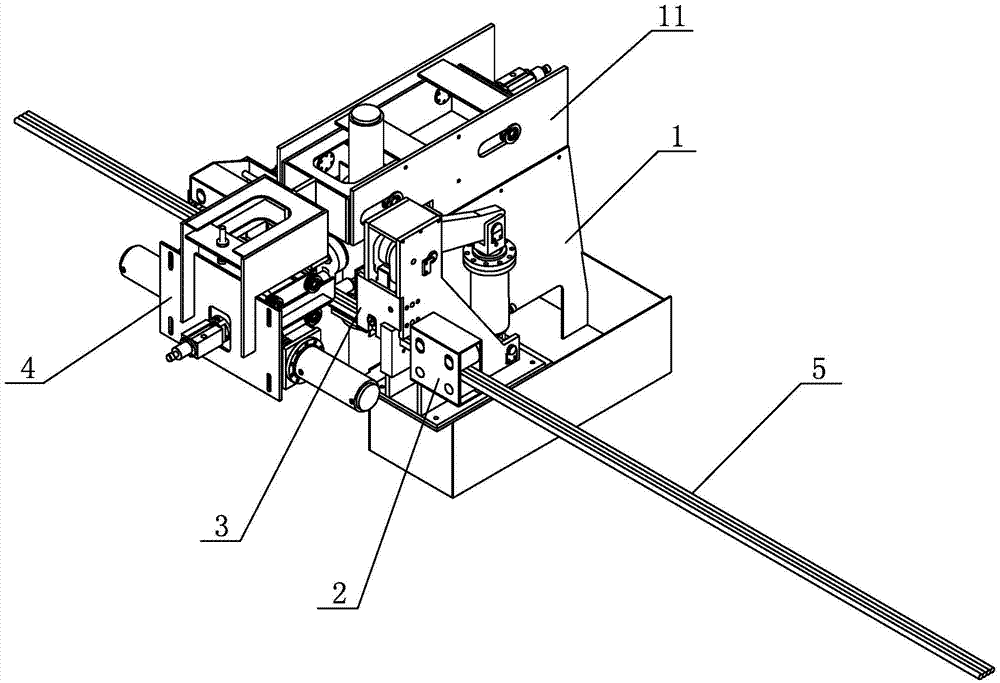

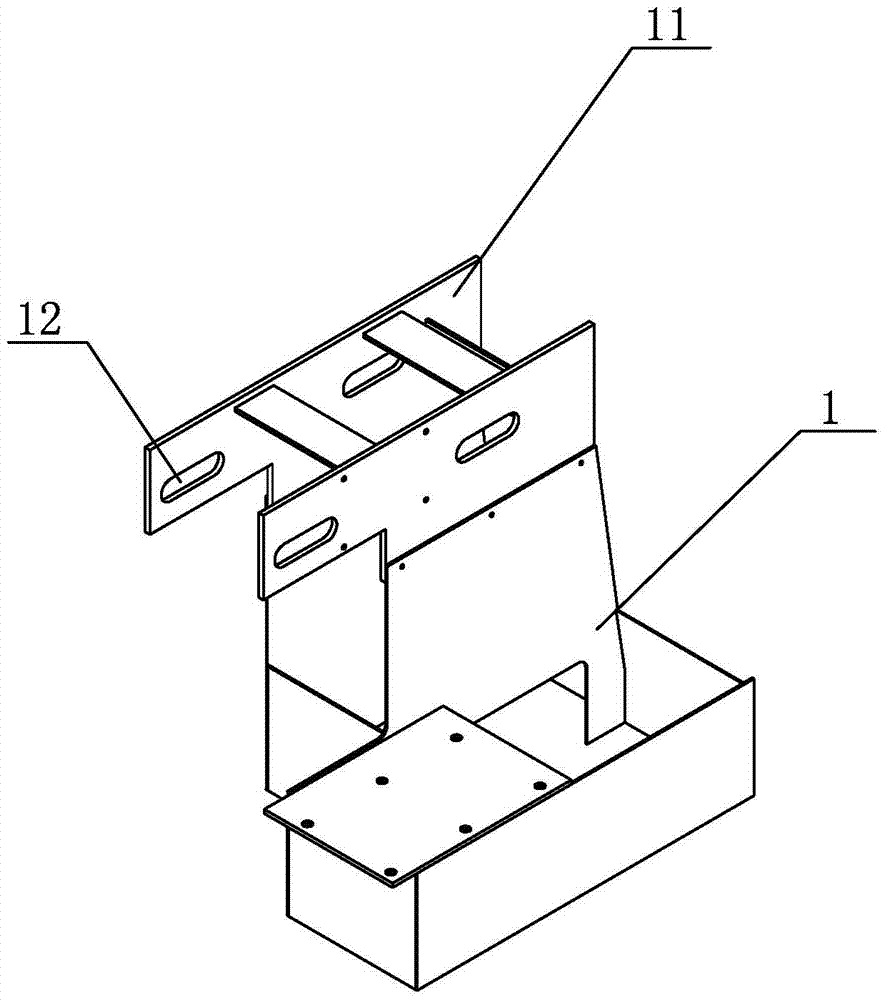

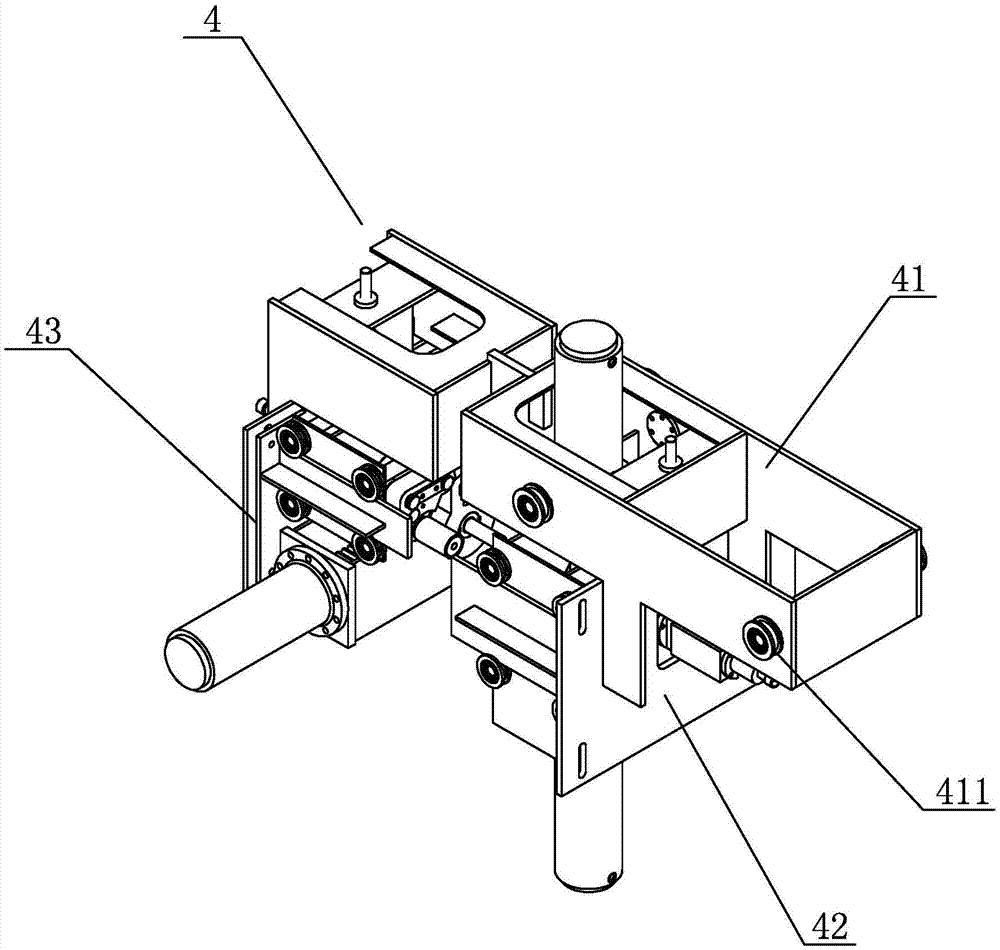

[0045] refer to figure 1 , The preferred embodiment provided by the present invention is an automatic segmental shearing and bending machine for wire rods, including a frame 1 on which a feeding mechanism 2, a dividing shearing mechanism 3 and a multi-directional displacement bending mechanism 4 are installed.

[0046] The feeding mechanism 2 adopts a roller or drum structure. Preferably, in this embodiment, a feeding mechanism 2 is provided in front of the multidirectional displacement and bending mechanism 4, and a second feeding mechanism 6 is also provided behind the multidirectional displacement and bending mechanism 4, and the feeding mechanism 2 is used for cutting The wire before cutting is fed, and the second feeding mechanism 6 is used to feed the cut wire, and the two feeding mechanisms are used together. At the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com