Polishing machine applied to aluminum plate surface machining

A surface processing and polishing machine technology, which is applied in the field of polishing machines, can solve the problems of general polishing effect of polishing machines, poor operation safety performance, and prone to safety accidents, etc., so as to improve operation safety performance, simplify installation steps, and compact and reasonable overall design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

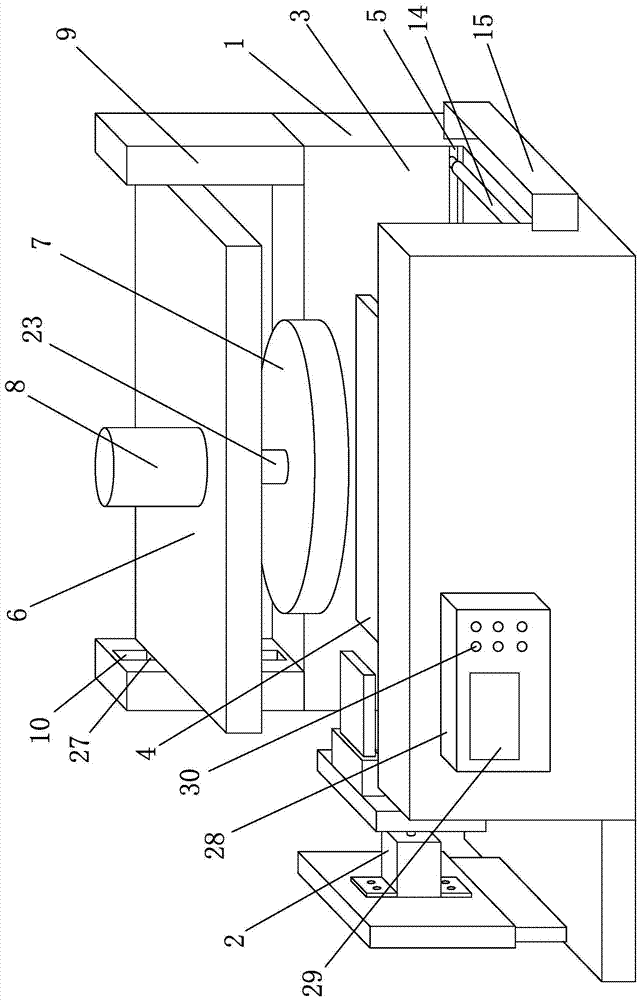

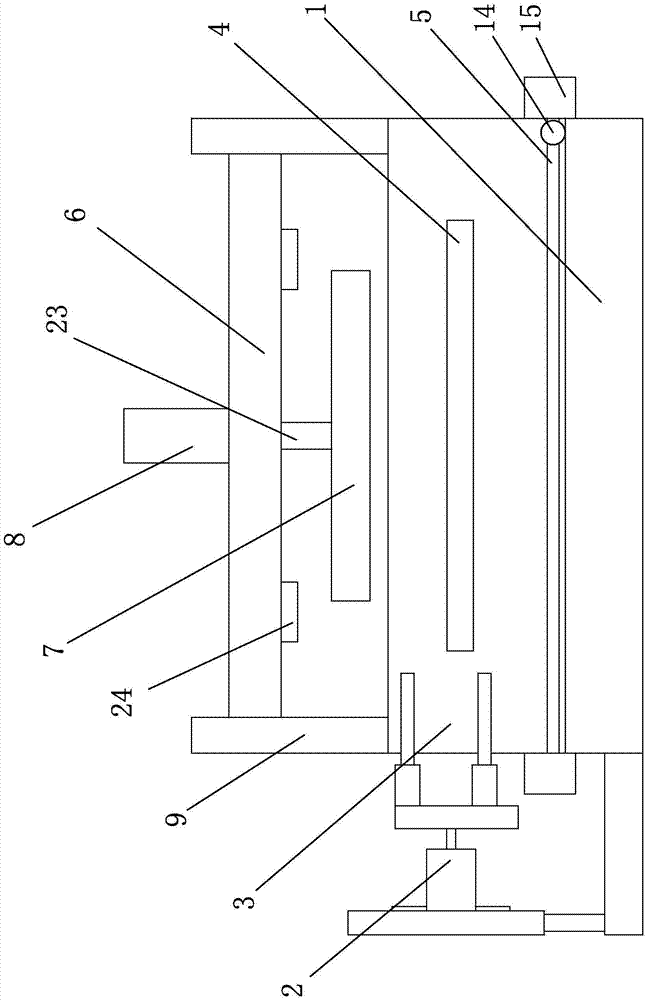

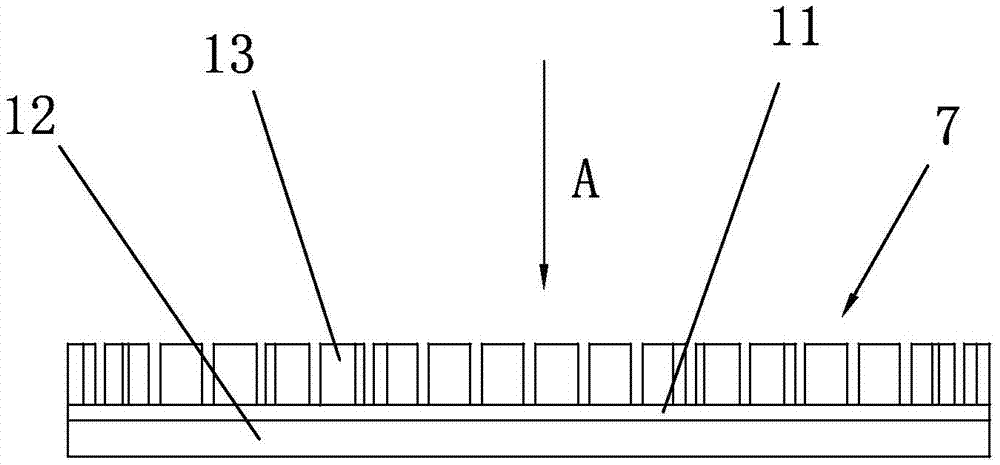

[0032] Such as Figure 1 to Figure 6 As shown, it is a polishing machine applied to the surface processing of aluminum plates according to the present invention, which includes a working platform 1, a polishing device, a cleaning device and a turning device 2. An operating platform 28 is arranged on the front end of the working platform 1, and an operating platform 28 is arranged on it. There is an operation display screen 29 and operation buttons 30, and the design of the operation console 28 makes the operation of the entire polishing machine more convenient and simple. Through the operation display screen 29, the processing conditions of the aluminum plate can be displayed more intuitively on the operation display screen 29 , so that the operator can find problems in time and avoid machining errors. Through the design of the operation button 30, it is convenient for the operator to open, close and set other parameters for the polishing machine. The design of the bit through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com