Polishing solution stirring device and method

A technology of a stirring device and a magnetic stirring device, which is applied in chemical instruments and methods, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of mechanical oil stains and impurities in polishing liquid, achieve enhanced stirring effect, and flexible placement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

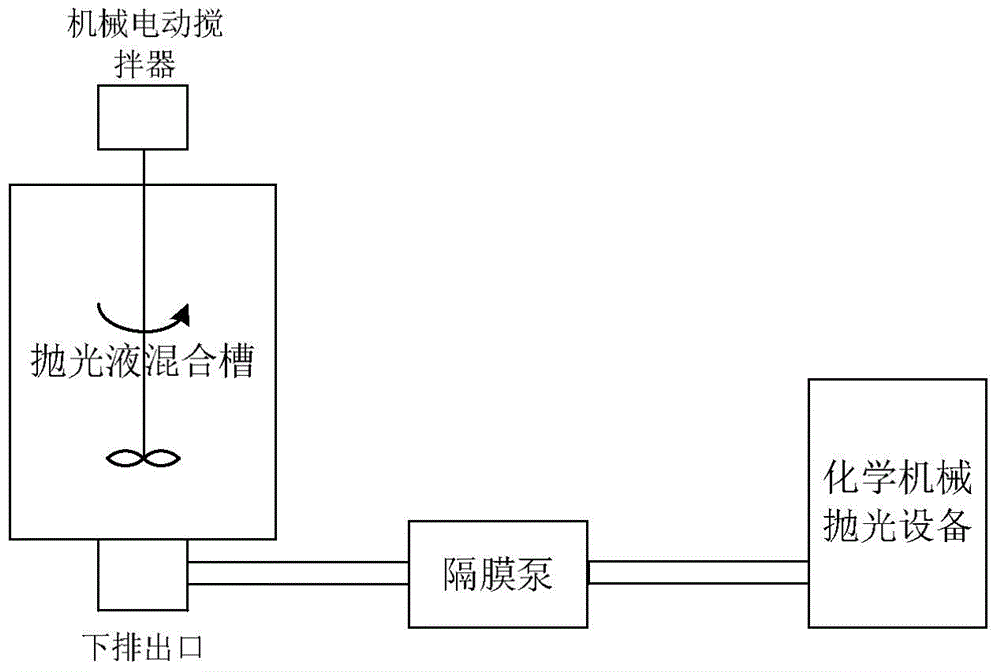

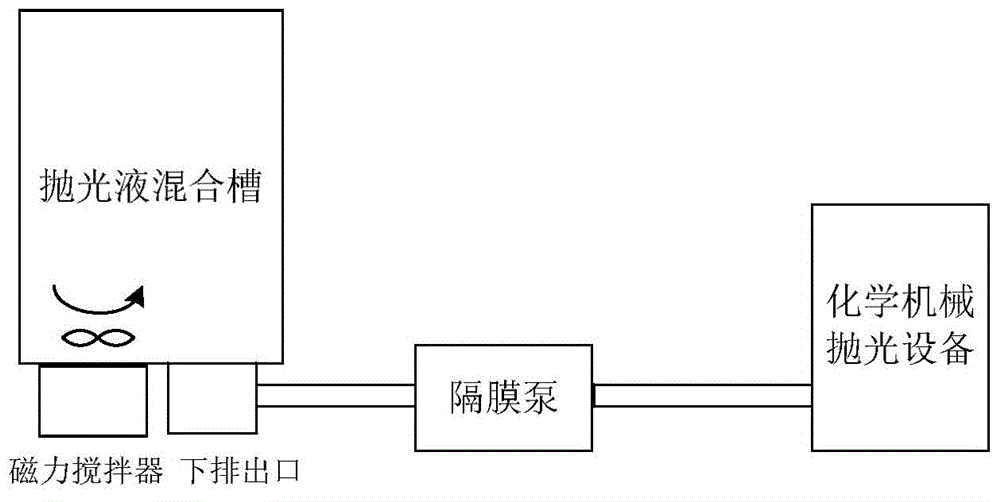

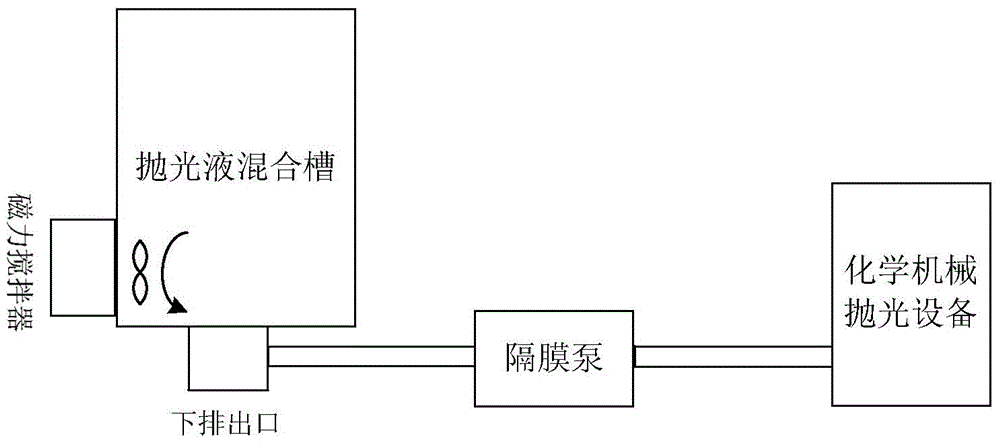

[0023] The invention provides a polishing liquid stirring device and method for directly stirring without using a mechanical motor, so as to avoid the problems of mechanical oil stains and other impurities. Specifically, the present invention provides a polishing liquid stirring device, the device comprising:

[0024] The mixing tank is used to hold the polishing liquid, and the bottom of the mixing tank has a lower outlet for the liquid to flow out;

[0025] A magnetic stirring device, including a magnetic stirrer fixed on the outside of the mixing tank, and a magnetic stirring rotor fixed on the inside of the mixing tank;

[0026] a diaphragm pump with a fluid inlet connected to a lower discharge at the bottom of the mixing tank; and

[0027] The chemical mechanical polishing equipment is connected to the fluid outlet of the diaphragm pump, and the polishing solution mixed in the mixing tank is supplied to the chemical mechanical polishing equipment through the isolation pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com