Composite reinforcing rib wall panel forming tool

A composite material and reinforcing rib technology, which is applied in the field of composite material wall panel forming tooling, can solve problems such as affecting flight safety and easy degumming, and achieve the effects of convenient and accurate positioning, good bonding and forming quality, and reliable forming and pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below.

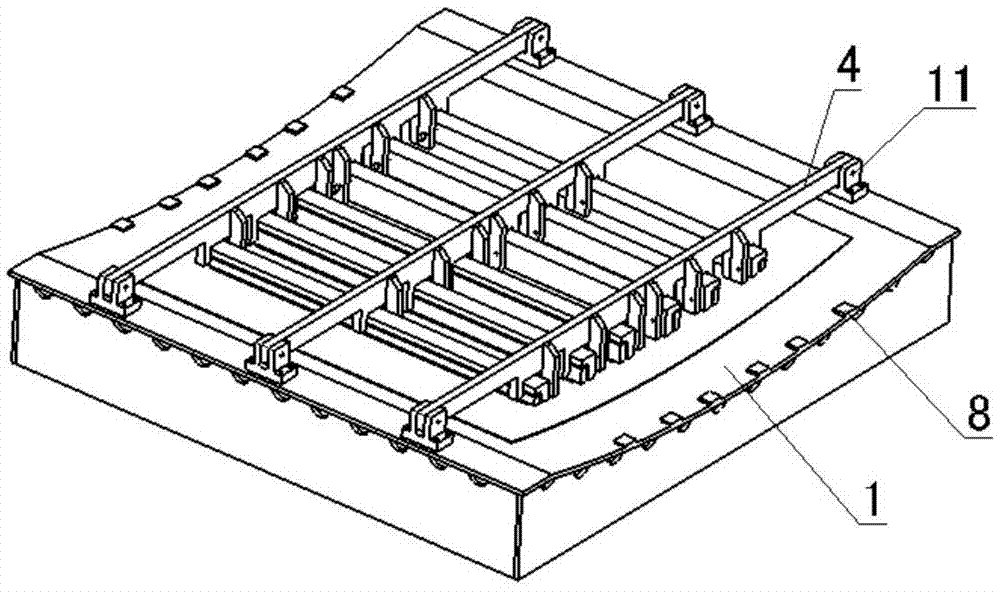

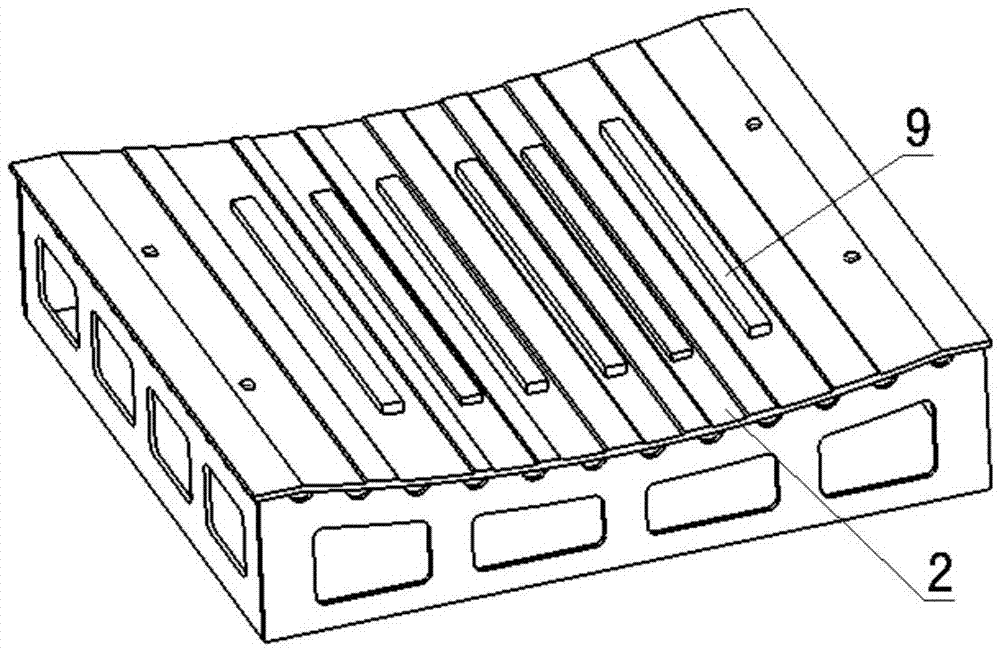

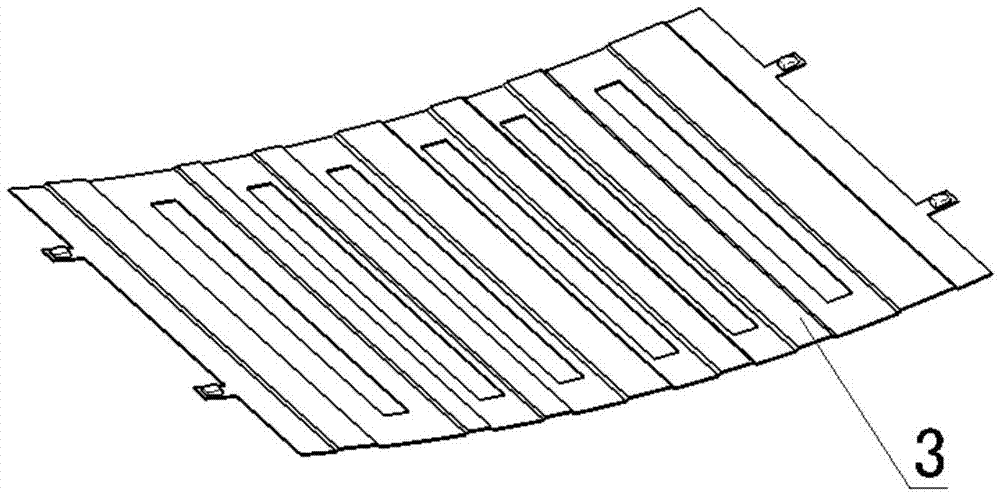

[0022] A composite wall panel forming tool with reinforcing ribs, the reinforcing ribs are in an inverted "J" shape, cover plate 3, positioner 4, positioning block 11, mandrel 5, rubber block 6, equalizing steel plate 7, wiring block 8. Occupying block 9, paving mold 10, compression screw 12, and vacuum bag 13. The mandrel 5 is used for paving materials in the C-shaped area on one side of the rib, and is also used for the positioning of the beam rib during the bonding forming process. The paving mold 10 is only used for laying the Z-shaped area on the side of the rib. The cover plate 3 is formed by the cover plate forming die 2, and its mold-adhesive surface is the upper surface of the wall panel skin, which is used to abut against the upper surface of the wall panel skin during the bonding process to ensure the forming quality. The cover plate forming die 2 is installed In the area of the reinforceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com