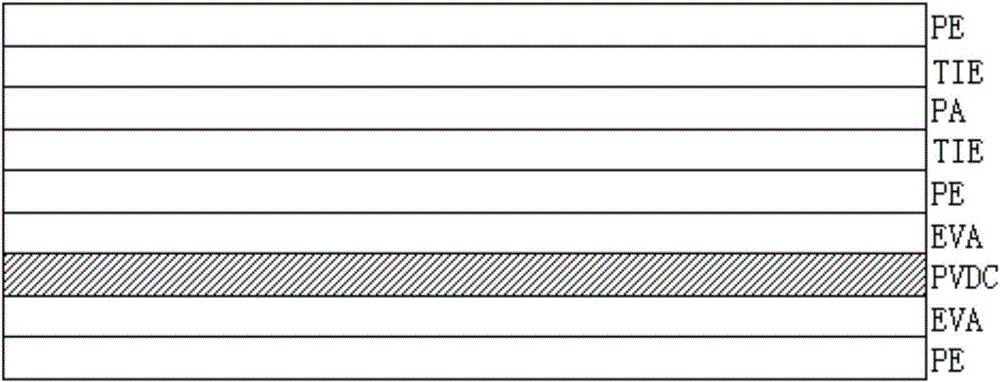

PE/TIE/PA/TIE/PE/EVA/PVDC/EVA/PE nine-layer co-extruded deep-drawing film

A PVDC and TIE technology, applied in the field of packaging materials, can solve problems such as the structure does not overcome the defects of the composite film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

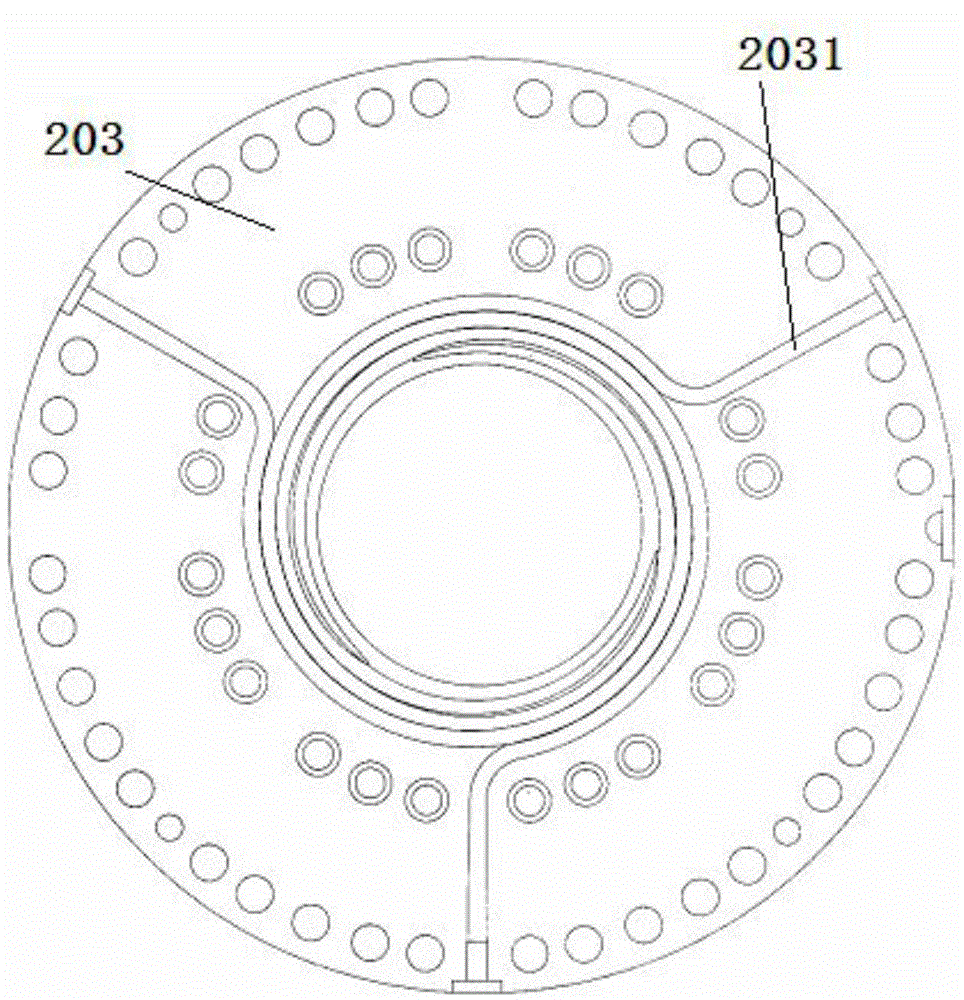

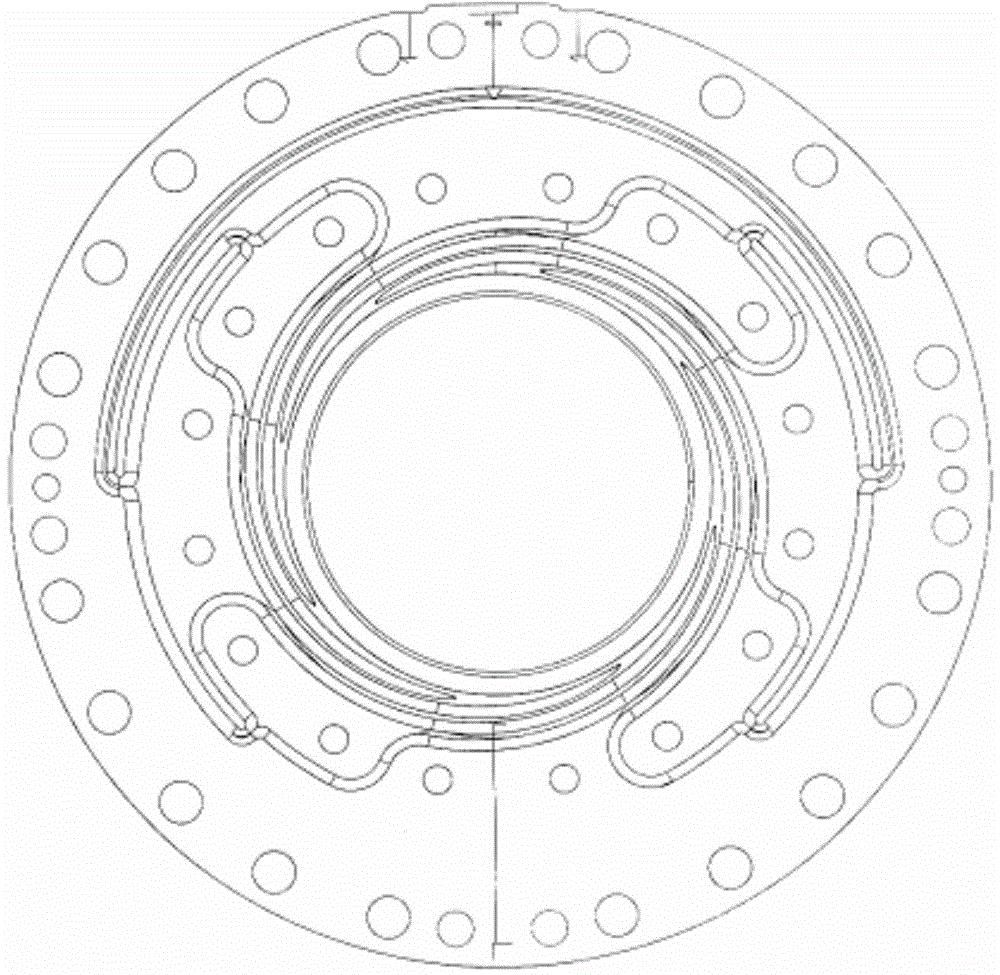

[0015] The present invention is specifically described below in conjunction with accompanying drawing, and the structure of 5 layers of co-extruded stretched film is as follows: figure 1 As shown, from outside to inside are PP or PE, EVA, PVDC, EVA, PE. The present invention adopts a kind of PVDC multi-layer co-extrusion mold to prepare, as figure 2 , image 3 As shown, the mold has a plurality of ring-shaped or tapered core columns, and multiple layers of mold layers for extruding different materials are arranged on the periphery of the core columns; flow channel; PVDC layer 203 adopts multi-entrance flow channel 2031 design, and three flow channels 2031 form a spiral shape at the center; make the raw material of each extruder of PVDC within 1 / 3 to the circumference during the molding process That's it. Other numbers of channels can also be used, such as 2, 4, etc., which can be set according to the thickness of the film and the number of layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com