Main cotton carding roller supporting device of carding machine

A supporting device and carding machine technology, which is applied in deburring devices, fiber processing, textiles and papermaking, etc., can solve problems that have not been seen in the corresponding enlightenment, and achieve the effect of raising height and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

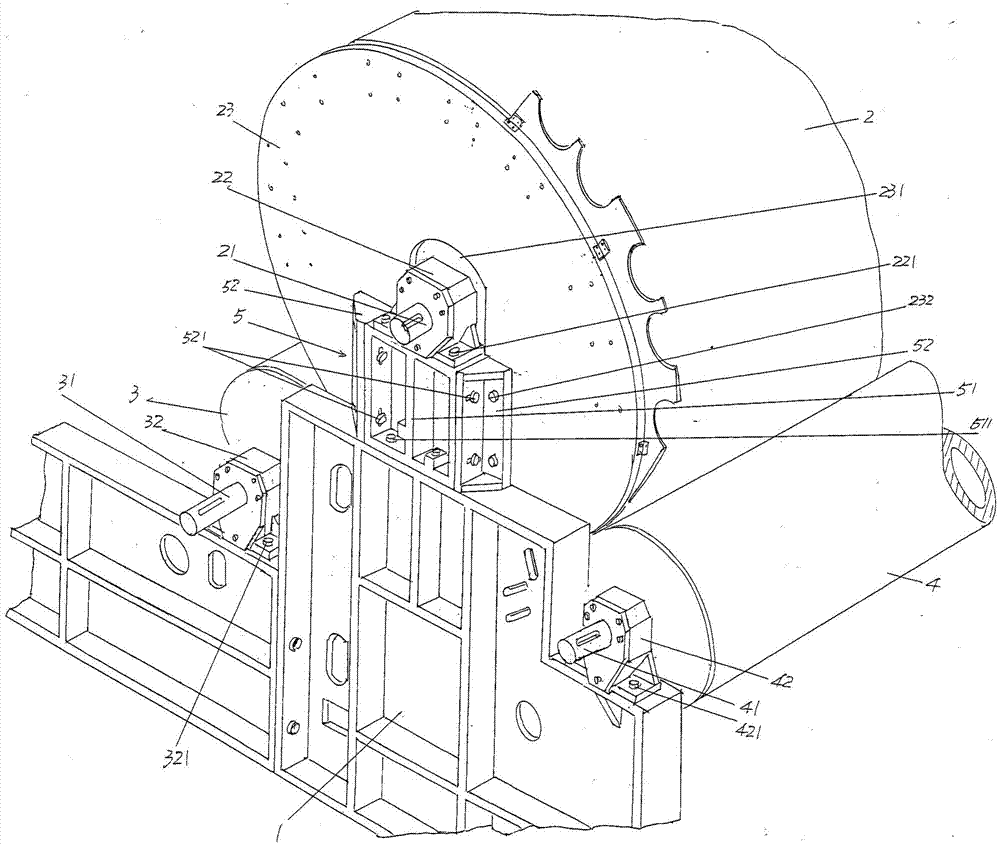

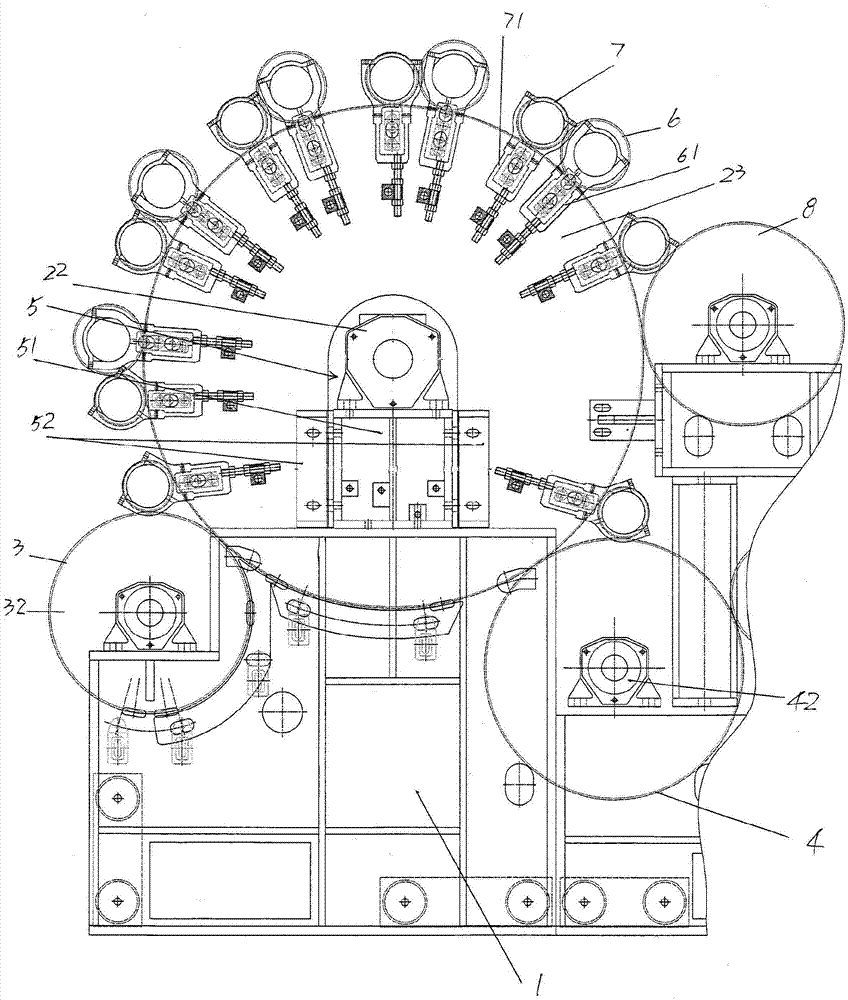

[0020] See figure 1 , a pair of frame wallboards 1 which belong to the structural system of the carding machine and are arranged face to face, and a main comb which is rotatably supported between the pair of frame wallboards 1 by the main carding roller shaft support bearing seat 22 Cotton roller 2, corresponding to the position below the left side of the length direction of main carding roller 2, is supported in the cotton-feeding disorderly roller 3 and Corresponding to the position below the right side of the length direction of the main carding roll 2, the lower air disorder roller 4 is rotatably supported between a pair of frame wallboards 1 by the lower air disorder roller shaft support bearing housing 42 . exist figure 1 Although only one of the pair of frame wall panels 1 on the front side is shown in the figure, it will not cause confusion for understanding. For the same reason, the aforementioned main carding roller shaft support bearing housing 22, Advancing the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com